Repuestos para Cummins 4B - Sección Conjunto de Reparación

Loading...

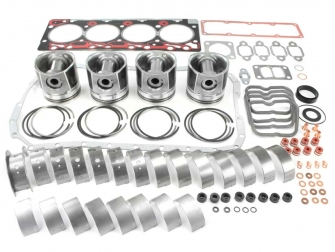

Loading... Cummins 4B Overhaul Kits – Complete Rebuild Parts and Accessories

At Diesel Pro Power, we specialize in providing complete overhaul solutions for Cummins 4B engines — the naturally aspirated, 3.9-liter diesel workhorse used in countless industrial, agricultural, and stationary applications. Our overhaul kits are engineered for simplicity, reliability, and compatibility, each matched precisely to Cummins CPL numbers and compression ratios to ensure a successful rebuild.

With over 40,000 satisfied customers and a reputation for fast shipping and expert support, Diesel Pro Power offers more than just rebuild kits. We provide the tools, filters, gaskets, and accessories you need to complete the job correctly and confidently.

Cummins 4B Engine Overview

The Cummins 4B is a 4-cylinder, 3.9L naturally aspirated diesel engine. It is part of the Cummins B Series and is designed without a turbocharger, making it simpler and more compact than the 4BT or 4BTA.

Key Specs:

-

Engine Type: Inline 4-cylinder, naturally aspirated

-

Displacement: 3.9 Liters (239 cu. in.)

-

Fuel System: Mechanical direct injection

-

Applications: Industrial power units, generators, agricultural machinery, compact construction equipment

Due to its mechanical design, the 4B remains popular in remote or rugged environments where reliability and ease of service are priorities.

When Should You Overhaul a Cummins 4B Engine?

Signs that your Cummins 4B engine needs an overhaul include:

-

Low compression

-

Increased blow-by

-

Hard starting or poor cold weather performance

-

Excessive oil consumption

-

Visible exhaust smoke

-

Poor fuel economy

-

Contaminants in oil or coolant

Rather than replacing the engine entirely, a full overhaul using the correct kit restores the original factory specifications and performance at a lower cost.

What’s Included in a Cummins 4B Overhaul Kit?

Each rebuild kit contains everything needed to refresh your 4B’s core rotating and sealing components. This includes:

-

Pistons and piston rings (matched to compression ratio)

-

Cylinder liners (wet sleeves)

-

Main bearings

-

Connecting rod bearings

-

Piston pins and retaining clips

-

Full upper and lower gasket sets

-

Front and rear crankshaft seals

Each kit is precision-matched to specific CPLs (Control Parts List numbers), ensuring correct fitment and performance.

CPL Number Compatibility – Choose the Correct Kit

Cummins uses CPL numbers to define exact engine configurations. Selecting the correct overhaul kit for your engine’s CPL ensures proper compression, fitment, and durability.

Overhaul Kit for Cummins 4B – Compatible with CPL Numbers:

2, 1965, 1966, 1967, 2109, 2144, 2302, 2351, 2359, 2396, 2478, 2599, 2623, 8442

Standard compression pistons. Common for general industrial and stationary 4B builds.

Overhaul Kit for Cummins 4B – Compatible with CPL Numbers:

1839, 2001, 2195

Designed for regional and early production engines. Includes matched compression components.

Overhaul Kit for Cummins 4B – Compatible with CPL Numbers:

2197, 8104

Features pistons with 15.3:1 compression ratio, ideal for emissions-sensitive or high-altitude operations.

Overhaul Kit for Cummins 4B – Compatible with CPL Numbers:

594, 595, 741, 1520, 1525, 2377, 696, 710, 793, 826, 937, 1173, 1278

Uses 16.5:1 compression pistons. Common in general-use industrial equipment.

Overhaul Kit for Cummins 4B – Compatible with CPL Numbers:

591, 681, 721, 725, 843, 895, 981, 1172, 1259, 1312, 1522, 1932

Includes 17.3:1 compression ratio pistons for better combustion and improved cold starts.

Overhaul Kit for Cummins 4B – Compatible with CPL Numbers:

690, 727, 730, 762, 763, 817, 857, 858, 1201, 1202, 1209, 1268, 1277, 1287, 1508, 1631, 1659, 2021, 2272, 2273, 2340, 2414

This kit features 17.5:1 compression pistons—the highest for 4B engines, supporting increased combustion pressure.

Compression Ratio Guide

Using the correct compression ratio is essential. Mismatching can cause:

-

Power loss

-

Poor starting

-

Overheating

-

Premature wear

Quick Reference:

-

15.3:1 – Lower compression for emissions or specialized uses

-

16.5:1 – Standard industrial setup

-

17.3:1 & 17.5:1 – High-efficiency or cold-start optimized configurations

Supporting Parts for a Complete Rebuild

Lower Gasket Set

Covers critical sealing surfaces like the oil pan, front cover, and rear main. Required when disassembling the lower end.

Expansion Plug Kit

Includes all freeze plugs for the 4B block. Replace them during rebuilds to prevent future coolant leaks.

Salvage Sleeve (Standard)

Used to restore scored or worn cylinder bores. Enables reuse of engine blocks that would otherwise need machining.

Piston Cooling Nozzles

Spray oil on the underside of the piston crown. Helps control temperature and reduce the risk of piston damage. One required per cylinder.

Filters and Fluids: Don't Reuse Old Components

Oil Filter

Protects your freshly rebuilt engine from break-in debris and contaminants.

Fuel Filter

Delivers clean diesel to injectors. A clogged filter can immediately damage rebuilt components.

Fuel/Water Separator

Removes water from diesel fuel. Critical for longevity in humid or marine environments.

Tools for a Professional-Grade Overhaul

Feeler Gauge (.002–.025 in)

Used to set valve lash during top-end reassembly. Accurate valve adjustment is key to performance.

Piston Ring Assembly Tool

Makes installation safer and cleaner. Prevents ring breakage and ensures proper seating.

Oil Filter Wrench

Designed for Cummins spin-on filters. Makes removal and installation easy and mess-free.

Fuel Filter Wrench

Specifically designed to remove large, high-torque fuel filters without damage.

Cooling System Essentials

Radiator Cleaner

Flushes corrosion and debris from the cooling system. Helps ensure your rebuilt engine runs at proper temperature.

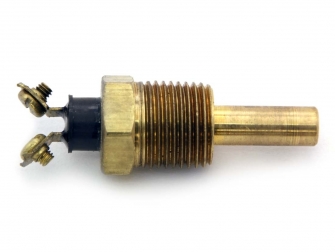

Temperature Switch

Triggers cooling fans or warning lights at 205°F. A valuable safety feature to protect your investment.

Engine Monitoring: Mechanical and Electrical Gauges

Post-rebuild, accurate monitoring is essential. We offer:

-

Mechanical oil pressure gauges

-

Coolant temperature gauges

-

12V and 24V electrical gauge options

Replace outdated or inaccurate gauges to protect your engine during break-in and beyond.

Frequently Asked Questions About Cummins 4B Overhaul Kits

Do I need to pull the engine to rebuild it?

Usually yes. Full overhauls require access to the crankshaft and liners. However, some top-end repairs can be done in-frame.

How many hours can I expect after a rebuild?

With quality parts and proper maintenance, a rebuilt Cummins 4B can last 10,000 to 20,000+ hours depending on load and operating conditions.

Do I need machine work?

That depends on engine wear. We offer salvage sleeves and standard-sized parts for light rebuilds, but blocks with heavy wear may require machining.

Additional Resources

2007 Cummins 4B Cylinder Compression Specs Explained: A Comprehensive Guide

A Step-by-Step Guide to Installing a Cummins 4B Sea Water Pump

Practical Guide to Servicing Your Cummins 6B, 6BT, 6BTA, 4B, 4BT, 4BTA Engines

FAQ: Servicing Cummins 6B, 6BT, 6BTA, 4B, 4BT, 4BTA Engines

Introduction - Cummins B Series Engines (6B, 6BT, 6BTA, 4B, 4BT, 4BTA)

Understanding Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

General Maintenance Requirements for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Oil and Lubrication Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Cooling System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Fuel System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Air Intake and Turbocharger Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Cylinder Head and Valve Adjustment for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Electrical System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Exhaust System and Emissions Control for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Common Problems and Troubleshooting Guide for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Major Overhaul and Rebuild Considerations for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Storage and Long-Term Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Recommended Aftermarket Parts for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Conclusion: Ensuring Long-Term Reliability for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Gratis a USA: 1-888-433-4735

Gratis a USA: 1-888-433-4735 Internacional: 305-545-5588

Internacional: 305-545-5588