Repuestos para Cummins 4BT - Sección Conjunto de Reparación

Loading...

Loading... Cummins 4BT Overhaul Kits – Complete Rebuild Parts and Accessories

Diesel Pro Power provides a comprehensive selection of Cummins 4BT overhaul kits and supporting parts for complete engine restoration. As the turbocharged sibling of the 4B, the 4BT engine delivers the same rugged durability with added performance from forced induction. Our overhaul kits are specifically matched to CPL numbers and compression ratios to ensure correct fitment and factory-grade performance.

Whether you run your Cummins 4BT in agricultural equipment, industrial machinery, marine auxiliary applications, or off-road platforms, Diesel Pro Power has the rebuild solution you need — backed by fast shipping and the trust of over 40,000 satisfied customers.

Cummins 4BT Engine Overview

The Cummins 4BT is a turbocharged 3.9-liter inline 4-cylinder diesel engine. It shares its displacement and basic architecture with the 4B but adds a turbocharger and other enhancements for higher power output and improved efficiency.

Key Specs:

-

Engine Type: Inline 4-cylinder, turbocharged

-

Displacement: 3.9L (239 cu. in.)

-

Fuel System: Mechanical direct injection

-

Applications: Agriculture, construction, marine auxiliary, power generation, repower projects

The 4BT is prized for its balance of power and simplicity. It remains a top choice for equipment where serviceability and performance are both priorities.

When to Rebuild a Cummins 4BT Engine

Typical signs that a Cummins 4BT needs an overhaul include:

-

Loss of power or compression

-

Turbocharger inefficiency

-

Excessive oil consumption

-

Fuel in the oil or coolant

-

Blue, white, or black exhaust smoke

-

Hard starts, especially in cold conditions

-

High blow-by or crankcase pressure

A complete rebuild restores compression, sealing, and internal clearances, extending the life of your engine by thousands of operating hours.

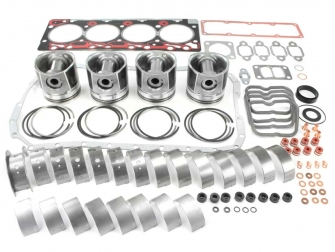

What’s Included in a Cummins 4BT Overhaul Kit?

Each Diesel Pro Power 4BT rebuild kit includes:

-

Turbo-rated pistons and rings

-

Cylinder liners

-

Connecting rod and main bearings

-

Upper and lower gasket sets

-

Piston pins and retainers

-

Front and rear crankshaft seals

All kits are CPL-matched and compression-specific, ensuring piston bowl shape and fuel delivery specs are correct for your engine.

CPL Number Compatibility – Select the Right Kit

Your Cummins engine's CPL (Control Parts List) number determines the correct rebuild kit configuration. Diesel Pro Power offers the following CPL-specific kits for the 4BT:

Overhaul Kit for Cummins 4BT – Compatible with CPL Numbers:

2, 1965, 1966, 1967, 2109, 2144, 2302, 2351, 2359, 2396, 2478, 2599, 2623, 8442

Overhaul Kit for Cummins 4BT – Compatible with CPL Numbers:

1839, 2001, 2195

Overhaul Kit for Cummins 4BT – Compatible with CPL Numbers:

2197, 8104

-

Compression ratio: 15.3:1

Overhaul Kit for Cummins 4BT – Compatible with CPL Numbers:

594, 595, 741, 1520, 1525, 2377, 696, 710, 793, 826, 937, 1173, 1278

-

Compression ratio: 16.5:1

Overhaul Kit for Cummins 4BT – Compatible with CPL Numbers:

591, 681, 721, 725, 843, 895, 981, 1172, 1259, 1312, 1522, 1932

-

Compression ratio: 17.3:1

Overhaul Kit for Cummins 4BT – Compatible with CPL Numbers:

690, 727, 730, 762, 763, 817, 857, 858, 1201, 1202, 1209, 1268, 1277, 1287, 1508, 1631, 1659, 2021, 2272, 2273, 2340, 2414

-

Compression ratio: 17.5:1

Matching Compression Ratio to Application

Compression Ratio Chart:

-

15.3:1 – Emissions-restricted or cold-climate operation

-

16.5:1 – Standard industrial and mixed-duty configurations

-

17.3:1 – High-efficiency applications

-

17.5:1 – Heavy-duty and high-pressure builds

Matching the correct ratio maintains fuel economy and prevents starting issues or combustion instability.

Additional Components for a Complete 4BT Rebuild

Lower Gasket Set

Includes oil pan, timing cover, and crank seals. Critical to resealing the engine.

Expansion Plug Kit

Fits Storm-type 4BT and 4BTA blocks. Prevents coolant leaks and ensures thermal integrity.

Salvage Sleeve (Standard)

Repairs worn cylinder block bores to accept new liners.

Piston Cooling Nozzles

Spray oil on the underside of pistons to manage heat. One required per cylinder.

Filters and Maintenance After Rebuild

Oil Filter

Prevents debris from circulating during engine break-in.

Fuel Filter

Essential to protect your new injectors and fuel pump.

Fuel/Water Separator

Keeps moisture out of the fuel system, critical in marine and humid environments.

Essential Rebuild Tools

Feeler Gauge (.002" to .025")

Required for accurate valve lash adjustment.

Piston Ring Installation Tool

Ensures rings seat without breakage or deformation.

Fuel and Oil Filter Wrenches

Sized for Cummins-specific filters to simplify maintenance.

Cooling System Support

Radiator Cleaner

Flushes scale and corrosion from coolant pathways.

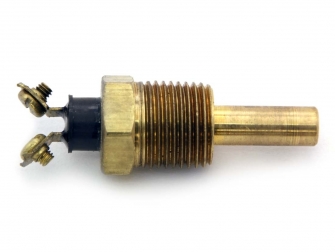

Temperature Switch

Triggers fan or warning light at 205°F. Helps prevent overheating.

Monitoring Gauges for Rebuilt 4BT Engines

-

Mechanical Oil Pressure Gauges

-

Coolant Temperature Gauges

-

12V and 24V Electric Gauges with Alarms

Install fresh gauges after rebuild to protect your investment.

FAQ: Cummins 4BT Overhaul Kits

How long does a rebuilt 4BT last?

Typically 10,000 to 20,000+ hours with proper break-in and maintenance.

Do I need machining?

That depends on wear. If cylinder liners or journals are out of spec, machining or salvage sleeves may be required.

How do I find my CPL number?

It's listed on the engine dataplate, usually riveted to the block or timing cover.

Additional Resources

2007 Cummins 4B Cylinder Compression Specs Explained: A Comprehensive Guide

A Step-by-Step Guide to Installing a Cummins 4B Sea Water Pump

Practical Guide to Servicing Your Cummins 6B, 6BT, 6BTA, 4B, 4BT, 4BTA Engines

FAQ: Servicing Cummins 6B, 6BT, 6BTA, 4B, 4BT, 4BTA Engines

Introduction - Cummins B Series Engines (6B, 6BT, 6BTA, 4B, 4BT, 4BTA)

Understanding Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

General Maintenance Requirements for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Oil and Lubrication Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Cooling System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Fuel System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Air Intake and Turbocharger Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Cylinder Head and Valve Adjustment for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Electrical System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Exhaust System and Emissions Control for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Common Problems and Troubleshooting Guide for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Major Overhaul and Rebuild Considerations for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Storage and Long-Term Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Recommended Aftermarket Parts for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Conclusion: Ensuring Long-Term Reliability for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Gratis a USA: 1-888-433-4735

Gratis a USA: 1-888-433-4735 Internacional: 305-545-5588

Internacional: 305-545-5588