Repuestos para Cummins 4BTA - Sección Conjunto de Reparación

Loading...

Loading... Cummins 4BTA Overhaul Kits – Complete Turbocharged Rebuild Solutions

Diesel Pro Power offers a premium selection of overhaul kits and supporting components for Cummins 4BTA engines. As the turbocharged and aftercooled variant of the legendary B Series platform, the 4BTA delivers dependable power in demanding environments—from marine auxiliary setups to industrial machinery and mobile equipment.

Our Cummins 4BTA overhaul kits are precision-engineered to match OEM specifications and CPL numbers, ensuring your rebuild restores factory-level performance and long-term durability. With over 40,000 customers worldwide, Diesel Pro Power is a trusted source for reliable engine overhaul components and fast global shipping.

Cummins 4BTA Engine Overview

The Cummins 4BTA is a 3.9-liter inline 4-cylinder diesel engine equipped with both a turbocharger and an aftercooler. It shares the same base architecture as the 4BT but incorporates charge air cooling to increase thermal efficiency and horsepower output.

Key Specs:

-

Engine Type: Inline 4-cylinder, turbocharged and aftercooled

-

Displacement: 3.9L (239 cu. in.)

-

Fuel System: Mechanical direct injection

-

Induction: Turbocharged with aftercooling

-

Applications: Marine propulsion and auxiliaries, agriculture, construction, industrial platforms, gensets

The 4BTA is known for its excellent torque curve, long service life, and suitability for high-demand, high-temperature operating environments.

Indicators That a 4BTA Engine Needs Rebuilding

If your Cummins 4BTA is experiencing any of the following issues, an engine overhaul may be necessary:

-

Reduced power and turbo boost

-

Increased oil consumption or fuel dilution

-

Hard starting or rough idle

-

Blue or white exhaust smoke

-

Coolant loss with no external leaks

-

High blow-by or crankcase pressure

-

Detected wear during scheduled maintenance inspections

A proper rebuild restores your engine’s compression, internal clearances, and sealing integrity — critical for turbocharged, high-pressure diesel systems.

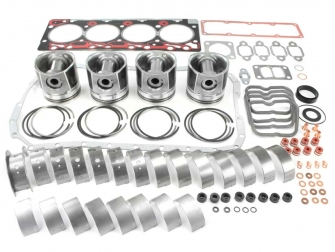

What’s Included in a 4BTA Overhaul Kit?

Each Cummins 4BTA rebuild kit from Diesel Pro Power includes:

-

Turbo-rated pistons matched by compression ratio

-

Piston rings and wrist pins

-

Cylinder liners

-

Connecting rod bearings

-

Main bearings

-

Full upper and lower gasket sets

-

Crankshaft front and rear seals

-

Retainers and snap rings

All kits are CPL-verified to ensure correct piston bowl design, fuel delivery geometry, and compression standards.

CPL Number Compatibility – Select the Correct 4BTA Kit

Diesel Pro Power organizes each 4BTA overhaul kit by its CPL (Control Parts List) compatibility. Always confirm your engine’s CPL number on the dataplate before ordering.

Overhaul Kit for Cummins 4BTA – Compatible with CPL Numbers:

2, 1965, 1966, 1967, 2109, 2144, 2302, 2351, 2359, 2396, 2478, 2599, 2623, 8442

Overhaul Kit for Cummins 4BTA – Compatible with CPL Numbers:

1839, 2001, 2195

Overhaul Kit for Cummins 4BTA – Compatible with CPL Numbers:

2197, 8104

-

Compression Ratio: 15.3:1

Overhaul Kit for Cummins 4BTA – Compatible with CPL Numbers:

594, 595, 741, 1520, 1525, 2377, 696, 710, 793, 826, 937, 1173, 1278

-

Compression Ratio: 16.5:1

Overhaul Kit for Cummins 4BTA – Compatible with CPL Numbers:

591, 681, 721, 725, 843, 895, 981, 1172, 1259, 1312, 1522, 1932

-

Compression Ratio: 17.3:1

Overhaul Kit for Cummins 4BTA – Compatible with CPL Numbers:

690, 727, 730, 762, 763, 817, 857, 858, 1201, 1202, 1209, 1268, 1277, 1287, 1508, 1631, 1659, 2021, 2272, 2273, 2340, 2414

-

Compression Ratio: 17.5:1

Compression Ratios and 4BTA Performance

Compression ratio impacts combustion efficiency, cold-start performance, emissions, and power output. The 4BTA’s turbocharged and aftercooled configuration requires matched piston and head chamber geometry.

Compression Ratio Chart:

-

15.3:1 – Lower pressure applications, emissions-compliant builds

-

16.5:1 – Standard-duty turbocharged 4BTA builds

-

17.3:1 – Optimized thermal performance for continuous loads

-

17.5:1 – High-torque applications or cold-weather use

Diesel Pro Power kits include pistons and gaskets that exactly match the required compression ratio.

Additional Components for a Complete Rebuild

Lower Gasket Set

Seals oil pan, timing gear housing, and crankshaft areas. Required whenever the short block is rebuilt.

Expansion Plug Kit (Storm Block)

Fits 4BTA and 4BT blocks with "storm-type" casting. Includes all necessary freeze plugs.

Salvage Sleeve (Standard)

Allows worn cylinder blocks to be restored to standard liner dimensions. A cost-effective solution to block damage.

Piston Cooling Nozzles

Spray oil beneath the piston crown to reduce operating temperatures. One nozzle is required per cylinder during a turbo rebuild.

Filters and Post-Rebuild Maintenance Parts

Oil Filter

Filters out metal debris generated during engine break-in. Use a new filter at initial startup and again after the first 20–50 hours.

Fuel Filter

Protects injectors and fuel pump from contaminants. Mandatory with every rebuild.

Fuel/Water Separator

Removes moisture that can cause injector pitting and pump damage — especially important in marine and high-humidity settings.

Essential Rebuild Tools for Cummins 4BTA

Feeler Gauge (.002"–.025")

Ensures precise valve lash adjustment after top-end reassembly.

Piston Ring Installation Tool

Prevents ring distortion and ensures proper cylinder wall seating.

Fuel Filter Wrench

Fits Cummins-style spin-on fuel filters to prevent damage during servicing.

Oil Filter Wrench

Specially designed to remove and install large-diameter Cummins oil filters with ease.

Cooling System Restoration

Radiator Cleaner

Flushes rust, scale, and deposits from internal coolant passages. A clean cooling system is essential for turbocharged engines.

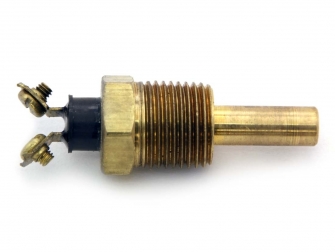

Temperature Switch (205°F)

Activates cooling fan or alarm circuit. Helps protect the 4BTA from overheating after rebuild.

Engine Monitoring After Overhaul

Replace any worn gauges to protect your investment and monitor the rebuilt engine’s health:

-

Mechanical Oil Pressure Gauges

-

Coolant Temperature Gauges

-

12V and 24V Electric Gauges

-

Gauges with Audible Alarms

Additional Resources

4BT Cummins Specs: A Detailed Overview

The Versatility of 4BT Cummins Engines: Specs and Applications

4BT Cummins Maintenance Schedule: What You Need to Know

A Step-by-Step Guide to Installing a Cummins 4BT Sea Water Pump

Practical Guide to Servicing Your Cummins 6B, 6BT, 6BTA, 4B, 4BT, 4BTA Engines

FAQ: Servicing Cummins 6B, 6BT, 6BTA, 4B, 4BT, 4BTA Engines

Introduction - Cummins B Series Engines (6B, 6BT, 6BTA, 4B, 4BT, 4BTA)

Understanding Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

General Maintenance Requirements for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Oil and Lubrication Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Cooling System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Fuel System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Air Intake and Turbocharger Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Cylinder Head and Valve Adjustment for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Electrical System Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Exhaust System and Emissions Control for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Common Problems and Troubleshooting Guide for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Major Overhaul and Rebuild Considerations for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Storage and Long-Term Maintenance for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Recommended Aftermarket Parts for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Conclusion: Ensuring Long-Term Reliability for Cummins 6B, 6BT, 6BTA, 4B, 4BT, and 4BTA Engines

Gratis a USA: 1-888-433-4735

Gratis a USA: 1-888-433-4735 Internacional: 305-545-5588

Internacional: 305-545-5588