Cummins 4B Engine Parts - Fuel Pump Section

Loading...

Loading... Fuel System Components for Cummins 4B Engine

The fuel system in the Cummins 4B 3.9L engine is the heart of its diesel combustion cycle. A precise and durable fuel pump setup ensures efficient fuel delivery, cold start reliability, and long-term durability in industrial and marine environments. Diesel Pro Power is proud to offer high-quality, in-stock fuel pumps and related components backed by 40,000+ satisfied customers worldwide.

This section covers everything from mechanical fuel pumps to fuel filter assemblies, fuel shutoff solenoids, gaskets, and Racor-style water separators—designed for rugged operation in commercial diesel engines.

Mechanical Fuel Transfer Pumps for Cummins 4B

The Cummins 4B fuel transfer pump plays a critical role in moving diesel from the tank to the injection system. On the 4B engine, these are most commonly mechanical lever- or piston-style pumps and are compatible with both rotary and inline injection systems.

Mechanical Lever-Style Fuel Transfer Pump

A robust lever-style mechanical pump is ideal for legacy Cummins 4B applications where simplicity and mechanical reliability are prioritized. This pump uses a manual diaphragm and spring-loaded lever to pull fuel from the tank and deliver it to the injection pump under low pressure.

-

Designed for 4B, 4BT, and 6BT engines

-

Compatible with rotary-style injection pumps

-

Simple installation using gasket and bolts

-

Ideal for field service, agriculture, and marine engines

This pump is often used in situations where battery-independent operation is required or where the use of an electric pump is not suitable.

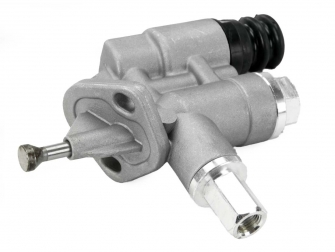

Mechanical Piston-Style Fuel Transfer Pump

The piston-style variant is engineered for higher reliability in applications with non-rotary (inline) injection pumps. It delivers consistent low-pressure fuel supply, even in environments with variable suction or long fuel lines.

-

Piston-style action with improved fuel metering

-

Often used in Cummins 4B engines paired with inline Bosch or similar mechanical injection systems

-

Built to meet industrial-grade service intervals

These two mechanical fuel transfer pumps form the foundation of the Cummins 4B low-pressure fuel delivery system and are supported by premium-quality gaskets.

Fuel Transfer Pump Gaskets & Installation Hardware

Fuel Pump Cover Plate Gaskets

Each mechanical fuel pump installation requires reliable sealing between the pump and engine block. Diesel Pro Power supplies OEM-style gaskets that are precision cut for the Cummins 4B, 4BT, and compatible models. Two gaskets are typically used per pump:

-

Provides secure fuel-tight seal

-

Made of durable materials to resist diesel and vibration

-

Compatible with 4BT, 6BT, 6CT, ISC, and QSC platforms

These gaskets are small, but critical. A leaking fuel pump gasket can cause suction problems, air intrusion, or premature pump wear.

Fuel Injection Pump Gasket for Cummins 4B

When servicing or replacing the fuel injection pump, it’s essential to install a new injection pump gasket. Diesel Pro Power provides Cummins-compatible injection pump gaskets for 4B, 4BT, 4BTA, 6B, and 6BT engines:

-

Maintains injection pump seal integrity

-

Designed to withstand high-pressure fuel exposure

-

Should be replaced during every pump removal

Proper installation prevents fuel leaks and ensures consistent pump timing and performance.

Fuel Shutoff Solenoids for 12-Volt Systems

An essential part of the Cummins 4B fuel system is the fuel shutoff solenoid, which controls diesel flow to the injection pump during engine start and shutdown. Our replacement solenoids are rated for 12-volt electrical systems, commonly found on marine and generator setups.

-

Used on 3.9L, 5.9L, and 6.7L Cummins engines

-

Securely mounts to pump housing or bracket

-

Rapid shutoff response improves safety

-

Prevents fuel leakage into cylinders when engine is off

Solenoids are a frequent failure point in older 4B engines and should be replaced if hard starting or failure to shut down occurs.

Fuel Manifolds for Cummins 4B and 4BT

The fuel manifold is a rigid distribution block that ensures even fuel delivery across cylinders in the 4B engine. Diesel Pro Power stocks factory-style fuel manifolds for the 4B and 4BT 3.9L engines, providing:

-

Even flow distribution to each injection line

-

Durable metal construction with corrosion resistance

-

Direct bolt-on compatibility with OEM configurations

Ideal for overhaul or replacement of damaged or corroded manifolds in marine or stationary Cummins diesel installations.

Fuel Filtration for Cummins 4B Engine

Clean diesel is the foundation of reliable operation. Our Cummins 4B fuel filtration products include standard filters, water separators, and Racor-style replacements. All filters are compatible with typical 4B filter heads using M16 x 1.5 thread sizes.

Standard Fuel Filter

-

Diameter: ~2.8 inches

-

Height: ~4.6 inches

-

Micron rating for effective diesel particulate capture

-

Direct-fit for most Cummins 4B installations

Fuel Filter with Water Separator

-

Incorporates water separation stage before final filtration

-

Used in marine, off-highway, and generator applications

-

Larger filter body (~5.6 inches height) for extended service intervals

Water in diesel can cause injector scoring, fuel system corrosion, and cold-weather starting issues. We recommend always using a water-separating filter in marine environments or humid climates.

Racor-Style Fuel Water Separators

Diesel Pro Power offers a complete selection of Racor-style filter assemblies and replacement elements, designed to separate water from diesel fuel before it reaches the injection pump.

These are ideal upgrades for Cummins 4B users in:

-

Marine vessels

-

Industrial power units

-

Standby generator sets

-

Agricultural machinery

Fuel Water Separator Assemblies

-

Available in 500, 900, and 1000 series sizes

-

Each includes a spin-on element with water-repellent media

-

Top-mounted clear bowls for water inspection and drainage

Replacement Filter Elements

All elements are available in 2 Micron (Brown top) and 30 Micron (Red top) variants:

-

2010 Series – Compatible with 500 Racor housings

-

2040 Series – For 900 Racor filter heads

-

2020 Series – Designed for 1000 Racor systems

Use finer 2-micron filtration for systems needing higher injection pump protection. Use 30-micron filtration for primary filtering upstream of fine filtration.

Fuel Filter Removal Tool

Diesel Pro Power offers a fuel filter wrench specifically sized for Cummins and Detroit Diesel filters ranging from 3-7/16" to 3-3/4" diameter.

-

Non-slip design with strong torque delivery

-

Reduces damage to filter housing during removal

-

A must-have for service technicians and fleet maintenance

Fuel System Pressure Switches

Our inventory includes make-break style fuel and oil pressure switches in multiple pressure ranges: 5 PSI, 10 PSI, 20 PSI, and 27 PSI. These switches are used to monitor system integrity or activate safety shutdowns and warning lights.

-

Threaded for 1/8" NPT ports

-

Electrical switching based on pressure thresholds

-

Compatible with Cummins and Detroit Diesel setups

-

Excellent for use in gensets, boats, and industrial machines

Proper use of pressure switches adds redundancy and can prevent serious engine damage due to low oil or fuel pressure conditions.

Marine Zinc Anodes for Fuel Coolers

Cummins 4B marine applications often include a fuel cooler to regulate diesel temperature during extended operation. These coolers may be equipped with sacrificial zinc anodes that prevent corrosion within the cooler body.

-

Threaded 3/8" NPT brass plug with 1” zinc core

-

Protects against electrolysis in saltwater environments

-

Should be inspected regularly and replaced as needed

Zinc replacement is an essential part of marine diesel maintenance—neglecting it can lead to catastrophic cooler failure and fuel contamination.

Mechanical and Electric Gauges for Fuel System Monitoring

Monitoring fuel pressure, oil pressure, and system voltage is crucial for Cummins 4B engines. Diesel Pro Power stocks:

-

Mechanical gauges (standard or with alarm contact)

-

Electrical gauges for 12V and 24V systems

These gauges are built to withstand vibration and temperature changes and are trusted by marine fleets, agriculture operators, and generator OEMs.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588