Cummins 6C Engine Parts - Fuel Section

Loading...

Loading... -

-

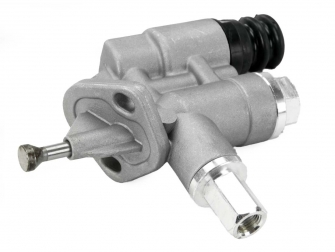

Cummins Fuel Transfer Pump

3918076

Pump Style Mechanical Piston, Used with rotary pumpsPrice: $ 64.68 -

Cummins Fuel Transfer Pump

3936319

Pump Style Mechanical Piston, Used with non-rotary pumpsPrice: $ 101.38 -

-

Cummins Fuel Filter

3890017

3.7" diameter, 5.46" height, thread: + 13/16- 18" - 14 UNF-28Price: $ 32.59 -

-

-

Cummins Fuel Filter & Water Separator

3286503

3.02" diameter, 5.62" height, thread: M16 x 1.5" - 6H INTPrice: $ 44.78 -

Cummins Injector Fuel Supply Tube Set for 6C, 6CT, 6CTA

3906783K

For cylinders 1, 2 and 3 Truck & Industrial applicationPrice: $ 213.13 -

Cummins Injector Fuel Supply Tube Set for 6C, 6CT, 6CTA

3906787K

For cylinders 4, 5 and 6 Truck & Industrial applicationPrice: $ 261.22 -

-

-

Hose Molded for Cummins 6C, 6CT & 6CTA engines

4019329

Hose for fuel cooler water inlet connectionPrice: $ 91.86 -

Hose Molded for Cummins 6C, 6CT & 6CTA engines

3866019

Hose for fuel cooler water outlet connectionPrice: $ 75.10 -

-

-

-

1000 Racor Replacement fuel and water separator filter unit

1000

Filter element 2020 includedPrice: $ 449.65 -

-

-

-

-

-

-

-

Fuel & Oil Pressure Switch - 10 PSI Make/Break

23520024

10 PSI make/break with 1/8 nptPrice: $ 99.79 -

Fuel & Oil Pressure Switch - 20 PSI Make/Break

23520025

20 PSI make, break with 1/8 nptPrice: $ 96.44 -

Fuel & Oil Pressure Switch - 27 PSI Make/Break

23511819

27 PSI make/break with 1/8 nptPrice: $ 81.10 -

Cummins 6C Engine Parts – Fuel System Components Catalog

The Cummins 6C engine is known for its balance of power, efficiency, and durability in a variety of industrial and marine roles. One of the most important systems that keeps this engine running at peak performance is the fuel system. From fuel transfer pumps to filters, injectors, and monitoring equipment, each component plays a vital role in ensuring consistent fuel delivery and optimal combustion.

This catalog focuses exclusively on fuel system components for the Cummins 6C engine, providing detailed descriptions to help you identify and select the correct part for your maintenance or overhaul project.

Fuel Transfer Pumps for Cummins 6C

The fuel transfer pump is responsible for moving diesel from the tank into the injection system. In the Cummins 6C, mechanical piston-style pumps are standard, designed for reliable operation under a range of load conditions.

Mechanical Piston Fuel Transfer Pump

The Cummins 6C uses a piston-type mechanical transfer pump engineered for steady, precise fuel delivery. Its durable internal components are designed to handle the high demands of industrial-duty cycles, ensuring consistent pressure to the fuel injection system.

Fuel Transfer Pump Gaskets

Every fuel transfer pump on a 6C engine requires proper sealing to maintain suction and prevent leaks. The Cummins fuel transfer pump gasket is made from fuel-resistant materials and fits precisely to the pump housing. On most setups, two gaskets are required per pump replacement to ensure long-term reliability.

Fuel Filters for Cummins 6C

Clean fuel is essential to maintaining injector life and preventing premature wear in the injection system. The Cummins 6C uses spin-on style fuel filters that are easy to replace and highly effective at capturing contaminants.

Standard Spin-On Fuel Filters

Designed to trap fine particles before they can enter the injection pump, these filters feature high-quality filter media and durable housings. Multiple filter sizes are available depending on the configuration of your 6C.

Fuel Filter & Water Separator Combination

In applications where moisture contamination is possible, a combination fuel filter and water separator is used. This unit removes water from diesel fuel before it reaches the injection system, protecting injectors and reducing corrosion risk.

Injector Fuel Supply Tubes

Fuel supply tubes transport diesel from the transfer pump to the injectors. On the Cummins 6C, these precision-engineered tubes must maintain high-pressure integrity to deliver consistent fuel flow.

-

Cylinders 1–3 Fuel Supply Tube Set – Feeds the front bank of cylinders with consistent fuel pressure.

-

Cylinders 4–6 Fuel Supply Tube Set – Feeds the rear bank of cylinders and ensures even combustion across the engine.

Worn or damaged tubes can cause leaks, misfires, and uneven fuel distribution, so timely replacement is essential.

Fuel Pump Shut-Off Solenoids

The fuel shut-off solenoid on a Cummins 6C is an electrically activated valve that stops fuel flow to the injection pump when the engine is shut down. Available in both 12-volt and 24-volt versions, the solenoid plays a critical role in engine safety and control.

-

12-Volt Solenoid – Common in standard electrical systems.

-

24-Volt Solenoid – Used in equipment with 24-volt setups, including many marine and heavy-equipment applications.

Fuel Cooler Water Hoses

Some Cummins 6C installations include a fuel cooler to regulate diesel temperature before it enters the injection system. Molded hoses connect this cooler to the engine’s cooling system.

-

Fuel Cooler Water Inlet Hose – Brings coolant into the fuel cooler for heat exchange.

-

Fuel Cooler Water Outlet Hose – Returns coolant to the main cooling circuit after diesel temperature has been reduced.

Fuel Filter Removal Tools

A proper filter wrench is essential for removing spin-on fuel filters from the Cummins 6C without damage. This wrench fits the standard filter sizes used on the 6C and ensures quick, clean removal during routine service.

Racor Fuel & Water Separator Systems

For many Cummins 6C applications, especially in marine environments, Racor water separator systems are used as the primary line of defense against fuel contamination. They are available in various sizes to match the engine’s fuel demand.

Racor Replacement Units

-

500 Series – Compact unit for moderate flow rates.

-

900 Series – Larger capacity for higher fuel consumption.

-

1000 Series – Maximum filtration for continuous-duty 6C installations.

Racor Filter Elements

-

Brown Top – 2 Micron – Fine filtration for maximum injector protection.

-

Red Top – 30 Micron – Coarse filtration for primary cleaning before secondary filters.

Fuel & Oil Pressure Switches

Pressure switches on the Cummins 6C monitor oil or fuel pressure and can trigger alarms or shut down the engine when pressure drops below safe limits. Available pressure settings include 5, 10, 20, and 27 PSI, these switches help protect the engine from lubrication or fuel starvation damage.

Fuel System Monitoring Gauges

Gauges allow operators to monitor fuel and oil pressure in real time. The Cummins 6C can use both mechanical and electrical gauges, depending on the installation.

-

Mechanical Gauges – Direct pressure reading via a physical connection.

-

Electrical Gauges – Use a sender unit for remote readings.

-

Alarm-Integrated Gauges – Combine monitoring with audible and visual warnings.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588