Cummins 6B Engine Parts - Cylinder Head Section

Loading...

Loading... Cylinder Heads & Related Components for Cummins 6B Engine

The Cummins 6B is a naturally aspirated 5.9L four-stroke inline six-cylinder diesel engine, widely used in industrial, marine, and agricultural equipment. Unlike its turbocharged variants—the 6BT and 6BTA—the 6B does not include a turbocharger, which means lower operating temperatures, reduced airflow demand, and simplified head design. Maintaining a healthy cylinder head is critical for ensuring reliable compression, optimal valve timing, and overall engine efficiency. This section provides a comprehensive overview of the cylinder head assembly and related components for the Cummins 6B, excluding references to 6BT or 6BTA models.

New Cylinder Head Assembly for Cummins 6B

A replacement cylinder head for the Cummins 6B engine is typically supplied fully assembled with valves and springs pre-installed. These new heads are cast to OEM specifications, ensuring durability and compatibility. They are ideal for operators dealing with cracked, warped, or otherwise damaged cylinder heads that can’t be repaired.

Key Features:

-

Pre-installed intake and exhaust valves

-

Pre-loaded valve springs

-

7mm injector tube ports

-

Cast iron construction

-

Compatible with marine and industrial configurations

-

No turbocharger ports or oil feed return lines

This head is engineered for direct fitment on the naturally aspirated Cummins 6B engine. No machining is required prior to installation.

Intake Valves for Cummins 6B

Each cylinder in the 6B engine uses one intake valve, totaling six valves per engine. Intake valves regulate the flow of the air-fuel mixture into the combustion chamber and must withstand high heat and pressure.

Intake Valve Highlights:

-

Hardened tip and stem for long life

-

Precision machined sealing face

-

Designed to operate with naturally aspirated flow characteristics

-

Works in conjunction with OEM valve guides and springs

Proper seating and sealing of intake valves are essential for maintaining compression and preventing air leakage. Always inspect for wear or carbon buildup when servicing.

Exhaust Valves for Cummins 6B

Exhaust valves allow the hot combustion gases to exit the cylinder. On the Cummins 6B, each cylinder also uses one exhaust valve, resulting in six total. These valves must withstand higher thermal loads compared to intake valves.

Features:

-

Forged or nitrided steel construction

-

Precision fit for 6B cylinder head guides

-

Compatible with valve rotators (described below)

-

Designed for long service intervals in marine and industrial settings

Exhaust valve failure can result in compression loss, blow-by, and overheating. Replace them if you observe pitting, cracking, or signs of valve seat recession.

Valve Rotators (Exhaust Only)

Valve rotators help evenly distribute wear across the valve face by rotating the valve slightly each time it opens. On the Cummins 6B, rotators are installed on the exhaust valves only.

Key Benefits:

-

Prevents hot spots and uneven seat wear

-

Reduces the likelihood of valve sticking

-

Extends exhaust valve service life

Rotators should always be inspected when replacing valves or valve springs. If they exhibit binding or irregular movement, replacement is recommended.

Valve Springs for Cummins 6B

Valve springs ensure that valves return to their closed positions quickly and maintain proper seating under pressure. The 6B uses distinct intake and exhaust valve springs.

Intake Valve Springs:

-

Optimized for lower spring force due to non-turbocharged application

-

Prevent valve float at operating RPM range

Exhaust Valve Springs:

-

Heavier construction for thermal resilience

-

Designed to maintain spring force under prolonged heat exposure

It’s important to use the correct spring for each valve type to avoid timing issues or valve seat damage.

Valve Guides and Seals

Valve guides provide a channel through which the valve stem moves. They stabilize valve motion and maintain alignment with the valve seat.

Intake and Exhaust Valve Guides:

-

Made from high-strength alloy or cast iron

-

Precisely machined to fit the 6B head

-

Require careful press-fit installation

Valve guide seals prevent oil from seeping into the combustion chamber via the valve stem. Replacing seals during any top-end rebuild helps prevent oil consumption and smoking issues.

Valve Inserts (Valve Seats)

Valve seat inserts are replaceable rings that provide a hardened sealing surface for the intake and exhaust valves. These are especially critical in industrial and marine environments where the engine experiences extended periods of heavy loading.

Intake & Exhaust Valve Inserts:

-

Machined from hardened steel or iron alloys

-

Interference fit into the cylinder head

-

Allow for reconditioning during rebuilds

Replacing worn or pitted valve seats is essential to restore compression and prevent valve blow-by.

Cylinder Head Bolts for Cummins 6B

Cylinder head bolts are critical for achieving proper torque and sealing between the head and engine block. The Cummins 6B uses two lengths of bolts depending on location within the head pattern.

Bolt Sizes:

These bolts are torque-to-yield and should not be reused. Always replace them during a head gasket or full top-end rebuild. Proper torque sequencing is critical to avoid warping the head or compromising the seal.

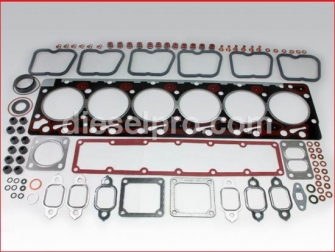

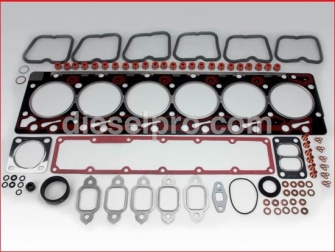

Gasket Sets for Cylinder Head Assembly

Standard Upper Gasket Set:

-

Includes cylinder head gasket

-

Intake and exhaust manifold gaskets

-

Valve cover gasket

-

Miscellaneous seals and o-rings

Oversize Gasket Set (0.25 mm):

-

For use after decking (resurfacing) the cylinder head or block

-

Helps maintain proper compression height

Always inspect gasket mating surfaces and clean thoroughly before installation. Never reuse head gaskets or seals.

Push Rods

Push rods transfer motion from the camshaft to the rocker arms in an overhead valve (OHV) engine like the Cummins 6B.

Features:

-

Precision-machined ends

-

Hardened construction for durability

-

Direct OEM length for 6B geometry

Bent or worn push rods can result in incorrect valve timing, misfires, or valve train noise.

Fuel Manifold (for Related Head-Mounted Applications)

Although not technically part of the head, the fuel manifold mounts to the cylinder head and distributes fuel to each injector. For the naturally aspirated Cummins 6B, fuel systems are mechanically timed and head-mounted components must remain in alignment.

Rocker Arm Hardware

Each cylinder on the 6B engine uses a rocker arm to actuate both intake and exhaust valves. The following hardware ensures proper function:

Heavy Hex Nuts:

-

Used to adjust rocker arm lash

-

Torque-sensitive—must be checked during every top-end service

Temperature Switch:

While not part of the cylinder head directly, the temperature switch is often located nearby and monitors coolant temperature. Ensuring accurate readings is essential to avoid overheating and head warping.

Installation Best Practices

-

Clean Surfaces Thoroughly: Before installing a new cylinder head, ensure both the head and block surfaces are completely clean and flat.

-

Follow Torque Specs: Use a calibrated torque wrench and follow the correct torque pattern when installing head bolts.

-

Pre-Lube Components: Lightly oil valve guides, push rods, and rocker arms to reduce wear during startup.

-

Check Valve Lash: Once the head is installed, set the valve lash to OEM specifications. Recheck after engine warm-up.

-

Use New Gaskets: Never reuse a head gasket or valve cover gasket.

Common Symptoms of Cylinder Head Issues

-

White smoke: May indicate a cracked head or failed head gasket leaking coolant

-

Loss of compression: Can stem from leaking valves or damaged valve seats

-

Overheating: Often caused by internal head cracks or warped deck surfaces

-

Oil in coolant: A clear sign of head gasket failure or internal head damage

Early detection and timely repair of cylinder head issues can prevent complete engine failure and costly downtime.

Why Choose Diesel Pro Power for 6B Cylinder Head Parts?

With over 40,000 satisfied customers, Diesel Pro Power offers one of the most complete selections of Cummins 6B engine cylinder head components online. All parts are inspected for quality and compatibility before shipping. Our knowledgeable team can help you select the correct parts based on your engine build and application. Orders ship fast, and support is available in English and Spanish.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588