Cummins 6B Engine Parts - Fuel Pump Section

Loading...

Loading... -

-

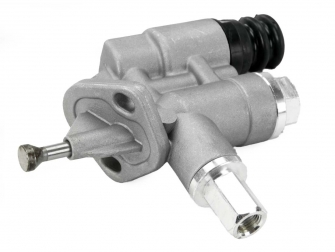

Cummins Fuel Transfer Pump

3936319

Pump Style Mechanical Piston, Used with non-rotary pumpsPrice: $ 101.38 -

-

-

-

-

-

Cummins Fuel Filter & Water Separator

3286503

3.02" diameter, 5.62" height, thread: M16 x 1.5" - 6H INTPrice: $ 44.78 -

-

-

-

1000 Racor Replacement fuel and water separator filter unit

1000

Filter element 2020 includedPrice: $ 449.65 -

-

-

-

-

-

-

Zinc for Cummins Marine Engine Fuel and Oil Coolers

3957921

Brass plug NPT 3/8”, zinc length 1”Price: $ 20.77 -

-

Fuel & Oil Pressure Switch - 10 PSI Make/Break

23520024

10 PSI make/break with 1/8 nptPrice: $ 99.79 -

Fuel & Oil Pressure Switch - 20 PSI Make/Break

23520025

20 PSI make, break with 1/8 nptPrice: $ 96.44 -

Fuel & Oil Pressure Switch - 27 PSI Make/Break

23511819

27 PSI make/break with 1/8 nptPrice: $ 81.10 -

Cummins 6B Engine Fuel Pump & Fuel System Components

The Cummins 6B engine is renowned for its reliability and versatility, serving in both marine and industrial applications worldwide. A critical element of its performance lies in its fuel delivery system—particularly the fuel pump, fuel filtration, and related components. This section provides a comprehensive look at all the essential Cummins 6B fuel system parts available through Diesel Pro Power, including mechanical and electrical components, filters, gaskets, shutoff systems, manifolds, pressure switches, and more.

With over 40,000 satisfied customers, Diesel Pro Power supplies genuine and aftermarket fuel system parts designed for durability, OEM-level fit, and optimal engine performance.

Mechanical Fuel Transfer Pumps for Cummins 6B

The fuel transfer pump is the heart of the 6B’s fuel delivery system. Its job is to pull fuel from the tank, deliver it to the injection system at the correct pressure, and ensure the engine runs smoothly under varying loads.

Lever-Style Mechanical Transfer Pump

This lever-actuated mechanical pump is engineered for dependable performance in demanding environments. It’s widely used in both 4BT and 6BT configurations and offers consistent fuel supply, even in high-vibration applications.

-

Robust metal housing resists corrosion.

-

Manual priming lever for ease of maintenance.

-

Common in marine applications where reliability is crucial.

Piston-Style Mechanical Transfer Pump

Designed for use with non-rotary injection pumps, this mechanical piston pump delivers smooth, constant fuel flow.

-

Precision-machined internals for efficient fuel delivery.

-

Works exceptionally well in industrial generator sets and stationary engine applications.

-

Reduced moving parts for longer service life.

Fuel Pump Gaskets & Seals

Cover Plate Gasket

These cover plate gaskets are used in pairs for each fuel pump installation. They ensure a tight seal between the pump and mounting plate, preventing fuel leaks that can reduce performance and cause air intrusion.

Fuel Injection Pump Gasket

The injection pump gasket provides a secure seal at the high-pressure pump connection.

-

Designed to handle the intense pressures of diesel injection systems.

-

Prevents fuel seepage that could lead to reduced efficiency or hard starting.

Fuel Shutoff Solenoids

12-Volt Fuel Shutoff Solenoid

This component electronically stops fuel flow to the injection pump when the engine is shut down.

-

Critical for safety in marine applications.

-

Allows remote shutoff in industrial installations.

-

Rugged coil and plunger design withstands high-heat environments.

Fuel Manifold Assemblies

While the 6B typically uses direct pump-to-injector lines, in some configurations (especially in 4B and 4BT engines) a fuel manifold is used to distribute fuel evenly.

-

Heavy-duty metal construction.

-

Prevents uneven fuel delivery that could cause cylinder misfires.

-

Ideal for multi-cylinder marine gensets.

Fuel Filtration Solutions

Proper fuel filtration is essential for diesel engine longevity. Contaminants like water, rust, and debris can cause injector damage and power loss.

Primary Spin-On Fuel Filters

Compact, easy-to-change filters designed to trap particulates before fuel reaches the injection pump.

-

High-efficiency filtration media.

-

Threaded mount for quick replacement.

Fuel Filter & Water Separator Units

Combined filter/water separator assemblies are essential for marine environments, where water contamination is common.

-

Separates water before it reaches injectors.

-

Clear bowl options allow for easy inspection.

-

Designed for high-flow diesel systems.

Fuel Filter Service Tools

Fuel Filter Removal Wrench

A specialized wrench designed to fit Cummins and Detroit Diesel fuel filters ranging from 3-7/16" to 3-3/4" in diameter.

-

Prevents damage to filter housings during removal.

-

Useful in tight engine compartments.

Racor Marine Fuel & Water Separator Systems

For vessels running Cummins 6B engines, Racor marine filtration is the gold standard in fuel cleanliness.

Racor Replacement Units

Available in multiple sizes (500, 900, and 1000 series) to match flow requirements.

-

Supplied with matching filter elements.

-

Durable marine-grade construction.

Racor Filter Elements

Available in different micron ratings:

-

2 Micron (Brown Cap) – For ultra-fine filtration in final-stage protection.

-

30 Micron (Red Cap) – For primary filtration and heavy contaminant removal.

All elements are designed for quick replacement without disassembling the filter housing.

Marine Fuel System Protection

Zinc Anodes for Fuel & Oil Coolers

In saltwater environments, zinc sacrificial anodes protect coolers from galvanic corrosion.

-

Threaded brass plug with replaceable zinc core.

-

Essential for marine cooling systems connected to the fuel system.

Fuel & Oil Pressure Switches

Monitoring system pressure is vital for avoiding catastrophic engine damage. Diesel Pro Power offers pressure switches for various trip points:

-

5 PSI Make/Break – Common for low-pressure warning systems.

-

10 PSI Make/Break – Often used for auxiliary alarms.

-

20 PSI Make/Break – Higher threshold for critical systems.

-

27 PSI Make/Break – For advanced shutdown systems in high-performance applications.

Each switch features 1/8 NPT threads for secure installation.

Gauges for Monitoring Fuel & Oil Systems

Accurate fuel and oil pressure readings are critical for preventive maintenance.

-

Mechanical Gauges – Simple, direct-read instruments for quick feedback.

-

Mechanical Gauges with Alarms – Provide visual and audible alerts.

-

Electrical Gauges – Available in 12V and 24V configurations for a variety of installations.

Maintenance Tips for Cummins 6B Fuel Pumps & Filtration Systems

-

Replace fuel filters regularly – Prevents injector wear and loss of power.

-

Inspect fuel pump gaskets – A leaking gasket can introduce air into the fuel system, causing hard starts.

-

Check for water in separators – Drain regularly in marine applications.

-

Monitor pressure readings – Sudden drops in fuel pressure may indicate a failing pump or clogged filter.

-

Protect against corrosion – In marine environments, keep zinc anodes in good condition.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588