Cummins 6BTA Parts - Gasket Section

Loading...

Loading... -

-

-

-

-

-

-

-

-

Cummins Oil Pan Gasket for 6B, 6BT & 6BTA Engines

4337597

Segmented Gasket. Included Oil pick up tube gasket.Price: $ 78.63 -

-

-

-

-

-

-

-

-

-

-

-

762 Hi-Temperature jointing compound for Detroit Diesel and Cummins turbos

762

225 gm tube - Temp range 550C to 760CPrice: $ 188.19 -

-

-

-

Cummins Heat Exchanger O Ring Gasket seal

3975186

2 per engine

For 4B, 4BT, 4BTA, 6B, 6BT and 6BTA engines.

Price: $ 7.35 -

Gasket Spray -High Tack Sealant (Hold & Seals Cut Gaskets)

99MA

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 25.67 -

3H Gasket Maker

3H

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 17.46 -

-

-

-

-

Gasket Maker - Ultra Blue RTV Silicone Sensor Safe

77BR

For Detroit Diesel & Cummins enginesPrice: $ 11.03 -

Cummins 6BTA Gasket Sets & Seals for Industrial and Marine Engines

When rebuilding, repairing, or maintaining your Cummins 6BTA engine—whether in a marine, industrial, or generator application—gaskets and seals play a critical role in ensuring long-term engine integrity. Diesel Pro Power carries a full selection of Cummins 6BTA gaskets, seals, and gasket makers designed to handle the high pressures and temperature demands of diesel engine performance. All our gaskets are compatible with 6BTA 5.9 engines and are engineered to OEM-level quality or better.

Whether you're working on a full in-frame rebuild or just need to replace a leaky manifold gasket, this section offers every gasket-related part you need—all in stock and ready to ship.

Complete Gasket Sets for Cummins 6BTA Engines

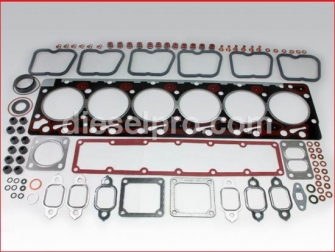

Upper Gasket Sets for Cummins 6BTA

Upper gasket sets cover the top-end of the engine including cylinder head, intake and exhaust manifold gaskets, valve cover seals, and turbo gaskets.

-

Standard Upper Gasket Set – 6BT Engines

Ideal for standard rebuilds with no machining modifications. Includes seals for the head, manifolds, valve cover, thermostat, and more. -

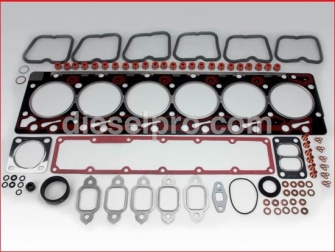

Oversized Upper Gasket Set – 0.25 mm

This gasket set is designed for engines that have had machining on the block or cylinder head. The thicker design helps maintain proper compression and sealing after resurfacing.

Each upper gasket set is engineered to meet Cummins 6BTA sealing requirements and resists high combustion pressures and thermal expansion.

Lower Gasket Sets for Cummins 6BTA

Lower gasket sets include all necessary gaskets and seals for the bottom-end of your Cummins engine—typically oil pan gasket, front and rear crank seals, timing cover seals, and other base components.

-

Lower Gasket Set – Front Gear Train Engines

Designed specifically for 6BTA engines with a front gear train configuration. Includes all gaskets and oil seals necessary to properly reseal the engine base.

Individual Gaskets & Seals for Cummins 6BTA Components

Exhaust & Intake System Gaskets

A leaking exhaust or intake manifold can drastically reduce engine performance and increase emissions. These gaskets are critical for maintaining turbo efficiency and preventing backpressure issues.

-

Exhaust Manifold Gasket

High-heat resistant gasket designed to maintain seal between exhaust manifold and cylinder head under extreme pressure. -

Exhaust Manifold Outlet Connection Gasket

Seals the outlet port of the exhaust manifold. Prevents soot leakage and preserves turbocharger efficiency. -

Intake Manifold Gasket

Designed to prevent air leaks in the intake manifold. Ensures optimal air-fuel mixture delivery to all cylinders. -

Turbo Mounting Gasket

Water-cooled turbo applications only. Ensures a leak-free seal between the turbocharger and exhaust components. -

Turbo Oil Drain Gasket

Seals the oil drain line connection on the turbocharger. Helps prevent oil leaks which can lead to turbo failure.

Cooling System Gaskets

The Cummins 6BTA's cooling system is vital in marine and stationary applications. The gaskets here are engineered to maintain pressure and prevent coolant leakage.

-

Gasket to Mount the Marine Water Pump

Specialized for marine configurations. Seals the raw water pump to the engine block, ensuring consistent coolant flow. -

Marine Water Pump O-Ring

Used on the inlet and outlet ports of the marine pump. Requires two per engine for a complete seal. -

Water Pan Seal Ring

Often overlooked during repairs, this seal ensures the pan that houses the water pump does not leak or lose pressure. -

Thermostat Seal

Helps maintain the integrity of the thermostat housing. Works in both marine and industrial configurations. -

Thermostat Housing Gasket

Prevents coolant leaks around the thermostat housing and ensures proper engine temperature regulation. -

Heat Exchanger O-Ring Gasket Seal

Used in both marine 4B, 6B, 6BT, and 6BTA engines. Ensures a secure seal within the heat exchanger to avoid water intrusion.

Lubrication System Gaskets

Oil leaks are a common culprit of premature engine wear. These gaskets help ensure tight seals in all lubrication system components.

-

Oil Pan Gasket

Heavy-duty sealing material prevents oil seepage from the oil pan under engine vibration and thermal cycles. -

Oil Cooler Core Gasket

Designed to maintain a leak-free seal around the oil cooler core, preventing oil and coolant mixing. -

Filter Head Gasket

Seals the oil filter head to the engine block or adapter plate. Prevents pressure loss and potential oil starvation.

Valve Train & Cylinder Head Seals

Valve cover and push rod seals play a crucial role in keeping oil inside the engine while allowing easy access during maintenance.

-

Valve Cover Gasket

Designed specifically for 4BT and 6BT engines. Provides a reliable seal around the top of the cylinder head. -

Push Rod Cover Gasket

Often replaced during valve adjustments. Ensures the push rod chamber remains sealed and leak-free.

Fuel System Gaskets for Cummins 6BTA

Proper sealing around the fuel injection and transfer pumps is crucial to avoid fuel leaks and maintain pressure.

-

Fuel Transfer Pump Gasket

Two gaskets required per pump. Seals the pump mounting area and prevents air intrusion into the fuel system. -

Fuel Injection Pump Gasket

Prevents leaks between the pump and timing cover. Compatible with all 6B-series engine variations.

Additional Sealants & Gasket Makers

For situations where traditional gaskets aren’t enough—such as pitted surfaces or irregular mating areas—diesel-grade sealants and jointing compounds provide long-term reliability.

-

762 Hi-Temperature Jointing Compound

Rated for temperatures up to 760°C, ideal for turbo and exhaust gasket reinforcement. -

Gasket Spray – High Tack Sealant

Spray-on tacky adhesive that holds gaskets in place during assembly. -

3H Liquid Sealant

Used for sealing fine scratches or imperfect sealing surfaces on Cummins and Detroit Diesel engines. -

High Strength Threadlocker (Red)

Secures fasteners subject to vibration. Recommended for manifold bolts and turbo mounts. -

RTV Silicone Gasket Makers

-

Sensor Safe (Blue) – General-purpose, safe around sensors.

-

High Temp RTV (Red) – For turbo and exhaust applications.

-

Ultra Blue RTV – Sensor-safe, resistant to high-pressure oil and coolant.

-

Non-Hardening Pliable Sealant – Remains flexible after curing, ideal for low-temp or low-torque covers.

-

J-B Weld – Cold Weld

Epoxy bonding solution for cracked metal housings or emergency repairs.

Common Applications for These Cummins 6BTA Gaskets

These gasket components are used in marine propulsion systems, commercial fishing boats, industrial generator sets, irrigation pumps, construction equipment, and more. Common platforms for Cummins 6BTA engines include:

-

Marine propulsion engines with raw water cooling

-

Diesel-powered generators in stationary installations

-

Industrial pumps for water and hydraulic systems

-

Off-road heavy equipment

-

Fire pump systems

-

Power units for construction and oilfield applications

Why Choose Diesel Pro Power for Cummins 6BTA Gaskets?

With over 40,000 satisfied customers worldwide, Diesel Pro Power provides fast shipping, excellent customer service, and the industry's most complete Cummins 6BTA gasket inventory. Our components are engineered for long-lasting reliability under high-load conditions common in marine and industrial environments.

Each gasket or seal is hand-selected to meet or exceed OEM standards, so you can perform repairs and overhauls with complete confidence. Whether you're doing a top-end rebuild or fixing a small coolant leak, we have you covered.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588