Cummins 6BTA Parts - Oil Section

Loading...

Loading... Cummins 6BTA Engine Oil System Parts Catalog

The Cummins 6BTA is a workhorse engine renowned for its performance in both marine and industrial applications. To keep this engine running reliably in demanding environments, the oil system must operate with precise efficiency. This section is dedicated to oil system components—including oil pumps, coolers, filters, gaskets, pressure switches, and more—engineered specifically for the Cummins 6BTA.

Diesel Pro Power is the trusted source for over 40,000 satisfied customers worldwide. Whether you're rebuilding an engine, replacing a worn-out pump, or performing preventative maintenance, we provide high-quality Cummins 6BTA oil system parts shipped fast and built to last.

Complete Oil Pump Solutions for Cummins 6BTA Engines

The oil pump is the heart of the lubrication system. Without a reliable oil pump, even the most well-built diesel engine can suffer premature wear. The Cummins 6BTA engine utilizes gear-driven oil pumps, and Diesel Pro Power offers premium replacements to match factory performance and fit.

Gear-Driven Oil Pump for Front Gear Train (23/24 Helix Teeth)

This oil pump is compatible with 6BTA engines featuring a front gear train and a 23/24 helix tooth configuration. These helix gears reduce gear noise and deliver smooth, efficient oil delivery under load.

Compatible with CPL Numbers:

591, 599, 714, 721, 742, 831, 1279, 1288, 1519, 1522, 1523, 1524, 1551, 1816, 1889, 1914, 1948, 1961, 1962, 1975, 2014, 2063, 2071, 2122, 2205, 2208, 2242, 2243, 2292, 2347, 2372, 2373, 2446, 2447, 2486, 2530, 2686, 2891, 2893, 8208, 8217, 8236, 8266, 8267, 8304, 8305, 8306, 8444

Applications:

-

Marine propulsion

-

Generator sets

-

Hydraulic power units

-

Commercial fishing vessels

-

Construction equipment

Features:

-

Precision-machined gears for consistent pressure

-

Helical gear design to reduce wear and vibration

-

Cast iron housing for long-term durability

-

Drop-in replacement for OEM fit

Straight Tooth Gear Oil Pump (22/24 Straight Teeth)

This version of the oil pump uses straight-cut gears, typically used in specific CPL-configured variants of the 6BTA engine. Straight tooth gears offer direct engagement and simplicity in design, useful in certain marine and industrial configurations.

Compatible with CPL Numbers:

742, 8206

Applications:

-

Heavy-duty stationary equipment

-

Marine auxiliary drives

-

Pumping systems

-

Agricultural tractors

Features:

-

Straight-tooth gears for direct torque transfer

-

OEM-quality design

-

Durable housing with precision-machined internals

Oil Cooler Assemblies for Cummins 6BTA

Keeping oil temperatures within the correct range is vital. Diesel Pro Power supplies high-efficiency Cummins oil coolers designed for the 6BTA engine platform.

5-Plate Oil Cooler

A 5-plate oil cooler is typically used in moderate-duty marine and industrial engines where oil flow and cooling requirements are balanced. The plate design promotes efficient heat exchange.

Applications:

-

Compact marine gensets

-

Light-duty industrial equipment

-

Marine propulsion systems under 250 HP

Benefits:

-

Compact design for tight engine rooms

-

Corrosion-resistant plates

-

Enhances oil longevity and engine efficiency

7-Plate Oil Cooler

For higher output engines or harsher environments, a 7-plate oil cooler provides added heat dissipation. More plates mean a greater surface area for cooling without sacrificing oil flow rates.

Applications:

-

Commercial marine propulsion

-

Generator sets with high-load duty cycles

-

Industrial compressors or pumps

Benefits:

-

Improved oil temperature control

-

Greater durability under prolonged operating heat

-

Compatible with QSB and ISB variants as well

Oil Filters for Cummins 6BTA

Oil filters ensure that contaminants are removed from the lubrication circuit, protecting bearings, camshafts, and pistons. Diesel Pro Power stocks high-performance spin-on filters specifically designed for the 6BTA engine.

Spin-On Oil Filter – Standard Length

Dimensions:

-

Outside Diameter: 3.66 inches

-

Height: 5.35 inches

-

Thread Size: 1-16 UN

This standard-length spin-on filter is designed to meet the lubrication needs of most 6BTA configurations. It balances high flow rate and filtration efficiency.

Use Case:

-

Routine maintenance intervals

-

Applications with low-to-moderate duty cycles

Spin-On Oil Filter – Extended Length

Dimensions:

-

Outside Diameter: 3.66 inches

-

Height: 6.95 inches

-

Thread Size: 1-16 UN

Designed for high-duty applications where extended service intervals or higher contaminant loads are expected. This filter offers more filtration media than the standard size.

Use Case:

-

Marine applications with high RPM load cycles

-

Generators running continuously

-

Equipment in dusty or contaminated environments

Oil Filter Removal Wrench

Working on your Cummins 6BTA engine? Diesel Pro Power carries a universal oil filter removal wrench designed to fit filter diameters from 4-21/32 inches to 5-5/32 inches. This wrench fits filters used in Cummins, Detroit Diesel, and Caterpillar engines.

Key Features:

-

Adjustable band design

-

Ideal for confined engine spaces

-

Durable handle and grip

Oil System Gaskets for a Leak-Free Seal

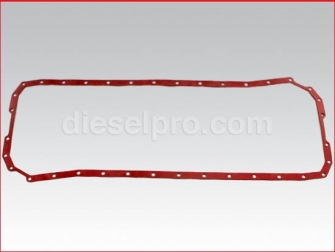

Cummins Oil Pan Gasket

The oil pan gasket is essential for keeping oil sealed inside the sump. Diesel Pro Power offers direct-replacement gaskets that match factory specifications, ensuring a snug, leak-free seal during engine rebuilds or service intervals.

Features:

-

Heat-resistant elastomer design

-

Precision cut for tight tolerance fit

-

Compatible with 4B and 6B series

Oil Cooler Core Gasket

Located between the oil cooler and engine block, this gasket must withstand extreme oil temperatures and pressure. Failure here can lead to cross-contamination or pressure drops.

Material:

-

High-density rubber with metal inserts

Key Benefits:

-

Prevents leaks at core junction

-

Maintains oil pressure stability

Filter Head Gasket

This gasket ensures a tight seal at the filter head assembly—where oil pressure begins its circulation through the engine. A faulty gasket in this area can cause oil starvation and pressure drops.

Compatibility:

-

4B and 6B engines

-

Marine and industrial oil filter assemblies

Fuel & Oil Pressure Switches

Monitoring oil pressure is critical for protecting engine internals. Diesel Pro Power offers multiple pressure switches that activate alarms or shut-off systems when pressure falls below safety thresholds.

Fuel & Oil Pressure Switch – 5 PSI Make/Break

This switch activates a circuit when pressure reaches 5 PSI. Ideal for low-pressure warning systems or start-up diagnostics.

Specifications:

-

1/8" NPT thread

-

Compact and reliable design

Fuel & Oil Pressure Switch – 10 PSI Make/Break

Commonly used as a safeguard in marine applications to trigger alarm systems if oil pressure drops too low.

Fuel & Oil Pressure Switch – 20 PSI Make/Break

Installed in engines running higher pressure oil systems, or those with stricter monitoring standards.

Fuel & Oil Pressure Switch – 27 PSI Make/Break

Designed for heavy-duty configurations where high-pressure alarm thresholds are required, such as in high-load generators or propulsion systems.

Oil System Zinc for Marine 6BTA Engines

Zinc anodes protect metal surfaces within the oil cooler and fuel cooler by sacrificing themselves to corrosion—essential for saltwater marine environments.

Zinc Plug Features:

-

NPT 3/8” brass plug

-

Zinc length: 1 inch

-

Prevents galvanic corrosion in marine oil coolers

Oil Pressure & Temperature Gauges

Whether your 6BTA is powering a fishing vessel or industrial equipment, monitoring oil pressure and temperature is vital. Diesel Pro Power offers reliable gauges:

Mechanical Gauges

-

No external power source required

-

Direct reading from engine systems

Electrical Gauges – 12V & 24V

-

Compatible with vessel electrical systems

-

Backlit for easy viewing in low light

-

Alarm integration available

Choosing the Right Oil Pump for Your CPL Number

When replacing your oil pump, it's essential to match the pump to the CPL number (Control Parts List) assigned to your Cummins 6BTA engine. Each CPL number reflects a specific engine configuration, and selecting the correct pump ensures proper gear meshing and lubrication performance.

If you’re unsure which CPL your engine has, you’ll find it stamped on the data tag located on the side of your engine block. Diesel Pro Power’s knowledgeable team can help cross-reference CPLs and ensure you receive the right component for your build.

Preventing Oil System Failures

Oil system problems are among the most common causes of catastrophic engine failure. Some best practices to follow when maintaining your 6BTA include:

-

Replace the oil pump at major overhaul intervals

-

Always use a new oil pan gasket when resealing

-

Check zincs during every oil change in marine applications

-

Replace filters with each oil change and monitor differential pressure

-

Use OEM-quality oil pressure switches and test alarm systems regularly

Applications: Where the Cummins 6BTA Oil System Shines

-

Marine Propulsion Engines: Tugs, trawlers, and pilot boats rely on clean, pressurized oil to handle rough operating conditions.

-

Standby Generators: Oil pumps ensure uninterrupted lubrication during high-RPM cycles.

-

Construction Machinery: Excavators, loaders, and cranes use 6BTA engines under heavy load; oil circulation is key.

-

Agricultural Equipment: Tractors and irrigation pumps rely on consistent pressure to manage field work.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588