Cummins ISB 5.9 Parts - Fuel Pump & Injector Section

Loading...

Loading... Cummins ISB 5.9 Fuel Pumps, Injectors & Fuel System Components

The Cummins ISB 5.9L diesel engine has earned a global reputation for unmatched reliability, versatility, and fuel efficiency in both industrial and marine applications. Whether powering fishing vessels, commercial generators, agricultural equipment, or construction machinery, the ISB 5.9 depends on a finely tuned fuel system to deliver consistent power and performance.

At the heart of this system are fuel pumps, injectors, filtration units, and various supporting components such as gaskets, manifolds, and pressure monitoring devices. A well-maintained fuel delivery system ensures clean, pressurized fuel reaches the combustion chamber in precise amounts, allowing for optimal combustion, reduced emissions, and extended engine life.

This detailed catalog explores every key part of the Cummins ISB 5.9 fuel system, explaining its function, maintenance requirements, and available aftermarket product options. You’ll also find expert installation guidance, troubleshooting tips, and component selection advice tailored to industrial and marine operators.

Overview of the Cummins ISB 5.9 Fuel System

The fuel system in the Cummins ISB 5.9 is engineered to maintain exact fuel delivery pressure and volume, even under high-load or continuous-duty conditions. In heavy-duty environments—especially marine service—fuel quality can vary significantly, making filtration, pressure control, and reliable pump operation essential.

Primary Fuel System Components

-

Fuel Transfer Pumps — Move fuel from the tank to the injection system under steady pressure.

-

Fuel Injectors & Injector Kits — Atomize fuel into a fine mist for efficient combustion.

-

Injection Pump Gaskets & Seals — Prevent leaks and maintain pressure integrity.

-

Fuel Filters & Water Separators — Remove particulates, debris, and moisture from the fuel.

-

Fuel Manifolds — Evenly distribute fuel to multiple injectors.

-

Pressure Switches & Gauges — Provide real-time monitoring and safety shutdown capability.

When each of these components is maintained with high-quality aftermarket parts, the ISB 5.9 runs more efficiently, produces more power per gallon of fuel, and operates cleaner.

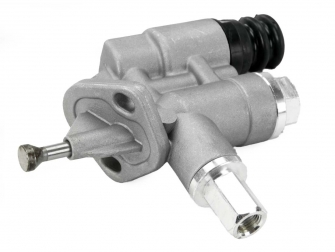

Fuel Transfer Pumps for Cummins ISB 5.9

Fuel transfer pumps are the first stage in the fuel delivery process, drawing fuel from the tank and supplying it to the injection system. The ISB 5.9 can use both mechanical lever-style and mechanical piston-style pumps depending on the configuration and CPL (Control Parts List) specifications.

Mechanical Lever-Style Transfer Pumps

-

Function: Operated via a camshaft-driven lever that moves a diaphragm, pulling fuel through inlet valves and pushing it toward the injection pump.

-

Advantages: Simple design, fewer moving parts, less susceptible to electrical failures.

-

Applications: Ideal for stationary engines, industrial generators, and marine vessels where reliability is critical and electrical systems may be limited.

Benefits for Marine Use:

-

Works reliably even in humid or salt-rich environments.

-

Less affected by electrical system faults caused by corrosion.

Mechanical Piston-Style Transfer Pumps

-

Function: Uses a reciprocating piston mechanism instead of a diaphragm for fuel movement.

-

Advantages: Higher fuel pressure output, suitable for engines using non-rotary fuel injection pumps.

-

Applications: Common in continuous-duty industrial machines and high-demand marine engines where sustained fuel pressure is essential.

Performance Notes:

-

Better suited for engines that operate under constant heavy load.

-

Offers longer service life in applications with variable fuel quality.

Maintenance Tips for Transfer Pumps

-

Inspect for leaks — Any diesel smell or visible seepage near the pump housing should be addressed immediately.

-

Replace gaskets at service intervals — Prevents fuel seepage and air intrusion.

-

Prime before startup — Especially after replacing a pump, ensuring proper fuel pressure before ignition.

-

Monitor starting performance — A weak pump may cause extended cranking or irregular idle.

Fuel Injection Components for the Cummins ISB 5.9

Injector Kits

Fuel injectors are precision-engineered to atomize diesel into a fine spray, enabling efficient combustion.

Key Features:

-

Compatible with multiple Cummins B-series engines, including the ISB 5.9.

-

Built to high-quality aftermarket standards for spray pattern, pressure, and fuel delivery.

-

Designed to match specific CPL numbers for perfect compatibility.

Why Replace Injectors?

-

Restored power and efficiency — Eliminates performance loss due to worn nozzles.

-

Reduced smoke output — Improves combustion quality.

-

Smoother engine operation — Reduces knocking and uneven idle.

Fuel Injection Pump Gaskets

-

Prevent fuel leaks at the pump-to-housing connection.

-

Maintain fuel system pressure integrity.

-

Essential whenever the pump is removed for service.

Fuel Filtration & Water Separation

Clean fuel is critical to the ISB 5.9’s performance. Even small amounts of dirt or water can cause injector wear, pump damage, and performance loss.

Standard Diesel Fuel Filters

-

Capture microscopic debris such as dust, rust, and carbon.

-

Protect injectors from abrasive wear.

Fuel Filters with Integrated Water Separation

-

Remove both solid contaminants and water — a common cause of corrosion and injector damage.

-

Essential in marine environments, where tank condensation is a frequent problem.

Racor-Style Fuel & Water Separator Systems

Widely used in marine, industrial, and heavy-duty truck applications for advanced filtration.

Available Sizes:

-

500 series — Compact; best for single small to mid-size engines.

-

900 series — Mid-capacity for commercial marine or industrial generators.

-

1000 series — High-flow filtration for large or multi-engine installations.

Micron Ratings

-

2 Micron — Captures extremely fine particles for maximum injector protection.

-

30 Micron — Best as a primary filter to capture larger debris before secondary filtering.

Best Practice: Use a two-stage system — 30 micron primary filter followed by a 2 micron secondary for optimal protection.

Fuel Manifolds

A fuel manifold evenly distributes pressurized diesel from the transfer pump to the injectors.

Benefits:

-

Maintains balanced fuel pressure across cylinders.

-

Prevents uneven combustion that can lead to rough running or cylinder imbalance.

-

Designed to withstand vibration and heat cycles in continuous-duty operations.

Fuel & Oil Pressure Monitoring

Pressure Switches

Available in calibrated settings (5, 10, 20, 27 PSI):

-

Trigger alarms or shutdown systems if pressures drop below safe limits.

-

Prevent catastrophic engine damage.

Installation Tip: Always use switches that match Cummins specifications for your CPL.

Gauges

-

Mechanical Gauges — Reliable, no power source required.

-

Electric Gauges — Available in 12V and 24V; integrate with modern dashboards.

-

Alarm-Integrated Gauges — Provide visual and audible warnings.

Fuel System Maintenance for Cummins ISB 5.9

Maintenance Best Practices:

-

Replace fuel filters at manufacturer intervals or more frequently in dirty conditions.

-

Drain water separators weekly in marine service.

-

Inspect hoses for softness, swelling, or cracking.

-

Keep spare filters and gaskets on board for marine applications.

-

Use diesel conditioners to prevent microbial growth.

Applications of the Cummins ISB 5.9 Fuel System

The ISB 5.9 fuel system serves:

-

Marine propulsion — Fishing boats, passenger ferries, workboats.

-

Industrial machinery — Stationary generators, water pumps.

-

Agriculture — Tractors, harvesters.

-

Construction — Excavators, loaders, cranes.

Why Choose Diesel Pro Power for Cummins ISB 5.9 Fuel System Parts?

-

40,000+ satisfied customers worldwide.

-

Expert technical support for correct part selection.

-

Fast, reliable international shipping.

-

Only high-quality aftermarket parts for maximum service life.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588