Cummins ISC Parts - Fuel Pump Section

Loading...

Loading... -

-

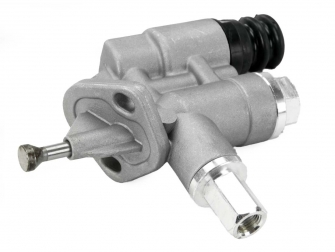

Cummins Fuel Transfer Pump

3936319

Pump Style Mechanical Piston, Used with non-rotary pumpsPrice: $ 101.38 -

-

Cummins Fuel Filter

3890017

3.7" diameter, 5.46" height, thread: + 13/16- 18" - 14 UNF-28Price: $ 32.59 -

-

-

-

-

-

-

-

1000 Racor Replacement fuel and water separator filter unit

1000

Filter element 2020 includedPrice: $ 449.65 -

-

-

-

-

-

-

-

Fuel & Oil Pressure Switch - 10 PSI Make/Break

23520024

10 PSI make/break with 1/8 nptPrice: $ 99.79 -

Fuel & Oil Pressure Switch - 20 PSI Make/Break

23520025

20 PSI make, break with 1/8 nptPrice: $ 96.44 -

Fuel & Oil Pressure Switch - 27 PSI Make/Break

23511819

27 PSI make/break with 1/8 nptPrice: $ 81.10 -

Cummins ISC Parts – Fuel Pump & Fuel System Components

The Cummins ISC engine is a proven mid-range diesel powerplant that relies on a precise and durable fuel delivery system. At the heart of this system is the fuel transfer pump, fuel filters, solenoids, and associated hardware that ensure clean, consistent fuel delivery under demanding marine and industrial conditions. Whether you are maintaining a commercial vessel, heavy-duty equipment, or a generator powered by a Cummins ISC, the health of your fuel system directly impacts performance, efficiency, and reliability.

Diesel Pro Power supplies a complete catalog of Cummins ISC fuel pump and related components, trusted by over 40,000 satisfied customers worldwide. Below, you’ll find an in-depth guide to each part, its role in the system, and how it integrates into the larger fuel supply network.

Fuel Transfer Pumps for Cummins ISC Engines

Mechanical Lever-Style Fuel Transfer Pump

The mechanical lever-style transfer pump is one of the most reliable methods of fuel delivery for Cummins ISC applications. This pump uses a lever mechanism driven by the engine camshaft to draw diesel fuel from the tank and push it into the injection system. Known for its simplicity, it provides consistent pressure without relying on electronics.

Key benefits:

-

Long service life under heavy-duty use

-

Dependable operation in marine and industrial settings

-

Compatible with earlier versions of Cummins ISC and similar mid-range engines

Mechanical Piston-Style Fuel Transfer Pump

Another option for Cummins ISC applications is the piston-style transfer pump. This design is typically used with non-rotary injection pump configurations, offering excellent pressure consistency. The piston design allows for smooth fuel delivery, making it suitable for ISC engines that operate at steady load conditions for long durations, such as in marine propulsion or generator applications.

Both pump types require a secure seal to prevent leaks and loss of fuel pressure, which leads to the importance of proper gaskets.

Gaskets and Seals for Cummins Fuel Transfer Pumps

Cover Plate Gasket

Every fuel pump requires high-quality gaskets to prevent leaks and maintain pressure. The cover plate gasket is a small but critical part of the Cummins ISC fuel pump assembly. Two gaskets are typically used per pump, ensuring a tight seal around the cover plate and preventing diesel fuel seepage.

Benefits of genuine Cummins gaskets:

-

Designed for perfect fit and alignment

-

Heat- and fuel-resistant materials for long life

-

Reduces the risk of fuel contamination due to leaks

Cummins ISC Fuel Filters

Fuel cleanliness is vital for protecting the injectors and pump of the Cummins ISC engine. Contaminated fuel can cause injector damage, loss of performance, and even catastrophic failure. Diesel Pro Power offers several spin-on fuel filters for the ISC and related Cummins engines.

Spin-On Fuel Filters

-

Standard spin-on fuel filter: Designed with durable housing and high-capacity filtration media, ensuring long service intervals.

-

Compact spin-on filter: Used where clearance space is limited while still offering excellent filtration efficiency.

-

High-capacity spin-on filter: Larger dimensions allow for more contaminant holding capacity, ideal for extended marine or industrial duty cycles.

Each filter is engineered with precise thread and sealing dimensions, ensuring compatibility with the Cummins ISC fuel system.

Fuel Pump Solenoids for Cummins ISC Engines

12-Volt Fuel Shut-Off Solenoid

The 12-volt shut-off solenoid is designed for Cummins ISC engines installed in applications with a 12V electrical system. Its role is to control the fuel supply by engaging and disengaging flow when the ignition is turned on or off.

Applications:

-

Marine propulsion engines with 12V controls

-

Industrial equipment with standard battery systems

24-Volt Fuel Shut-Off Solenoid

For vessels and equipment running on a 24V electrical system, the 24-volt solenoid provides the same function, ensuring reliable fuel shut-off.

Key advantages of both solenoids:

-

Quick engagement/disengagement

-

Prevents fuel flow when the engine is off, reducing safety risks

-

Durable design for repeated use under heavy load cycles

Fuel Filter Tools and Accessories

Fuel Filter Removal Wrench

Changing filters on a Cummins ISC is made easier with a fuel filter removal wrench. This tool is designed to fit standard Cummins and Detroit Diesel fuel filters, ranging from 3-7/16" to 3-3/4". It ensures a secure grip without damaging the filter housing, making maintenance faster and more reliable.

Racor Fuel and Water Separators

Fuel-water separation is essential in marine applications, where moisture contamination is common. Diesel Pro Power offers Racor replacement units and elements that pair well with Cummins ISC systems.

Racor Replacement Units

-

500 series: Compact yet effective, includes a 2010 filter element.

-

900 series: Mid-capacity separator with 2040 filter element.

-

1000 series: High-capacity unit for large marine or industrial diesel systems, includes a 2020 filter element.

Racor Filter Elements

Available in different micron ratings to suit specific operating conditions:

-

2 micron brown top: Provides ultra-fine filtration for maximum injector protection.

-

30 micron red top: Designed for primary filtration, removing larger contaminants and extending the life of downstream filters.

Fuel & Oil Pressure Switches for Cummins ISC Engines

Maintaining correct fuel and oil pressure is critical for Cummins ISC engines. Pressure switches provide alerts or automatic shut-off when pressure falls below safe operating levels.

Options include:

-

5 PSI make/break switch – Protects against critically low pressure.

-

10 PSI make/break switch – Common in ISC monitoring systems.

-

20 PSI make/break switch – Provides earlier warnings for low pressure conditions.

-

27 PSI make/break switch – Used in higher-sensitivity applications where proactive alerts are necessary.

Each switch is threaded for easy installation and compatible with both Cummins and Detroit Diesel systems.

Gauges for Monitoring Fuel and Oil Pressure

Reliable monitoring is essential for safe operation. Cummins ISC systems can be paired with a variety of gauges:

-

Mechanical gauges: Provide direct, accurate readings without reliance on power supply.

-

Mechanical gauges with alarms: Offer both visual and audible alerts for added safety.

-

Electrical gauges (12V or 24V): Integrate easily with modern control panels, providing consistent monitoring across different voltage systems.

Why Proper Fuel System Maintenance Matters for Cummins ISC Engines

The fuel system of a Cummins ISC engine is more than just a transfer pump—it’s a complete network of pumps, filters, solenoids, gaskets, switches, and monitoring equipment. Together, these components:

-

Ensure clean fuel delivery

-

Maintain correct pressure for efficient combustion

-

Prevent costly downtime from contamination or leaks

-

Protect sensitive injectors and pump internals

By choosing genuine Cummins and Racor components from Diesel Pro Power, you ensure maximum reliability, backed by the trust of over 40,000 global customers.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588