Cummins ISM Parts - Cylinder Head Section

Loading...

Loading... Cylinder Heads & Related Components for Cummins ISM

The Cummins ISM engine is a highly regarded heavy-duty diesel platform known for its balance of power, durability, and fuel efficiency. Designed for on-road commercial vehicles, power generation, and select industrial applications, the ISM offers high torque in a compact, efficient footprint. Over time, routine top-end service becomes essential to keep these engines operating at peak performance.

In this section of our Cummins ISM catalog, you'll find everything needed to service or replace the cylinder head and associated top-end components. Whether you're doing preventive maintenance, correcting a head gasket failure, or performing a full in-frame overhaul, we provide high-quality, ready-to-ship parts trusted by thousands of customers around the world.

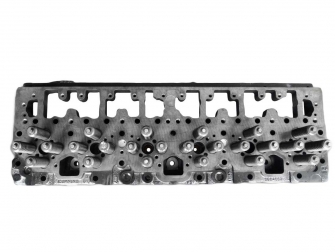

New Cylinder Head for Cummins ISM Engines

Our new ISM cylinder heads are preassembled and include installed intake and exhaust valves, springs, and retainers. These heads are engineered for direct replacement and eliminate the need for time-consuming valve installation and precision machining.

Key Benefits:

-

Ready-to-install with valve train components preloaded

-

Manufactured to meet or exceed OEM tolerances

-

Ideal for fleet rebuilds, power units, and generator sets

-

Compatible with ISM, M11, and QSM platforms (check application)

A new head is the best option for engines with cracked castings, warped sealing surfaces, or valve seat damage beyond repair. These cylinder heads restore lost compression, reduce oil consumption, and ensure longer engine life after top-end service.

Intake and Exhaust Valves

ISM intake valves manage the airflow into the combustion chamber during the intake stroke. They must withstand high stress and precise movement to maintain efficiency. Over time, these valves can wear or become pitted, which can cause:

-

Poor compression

-

Hard starting

-

Reduced power output

Replacing intake valves during a head rebuild ensures proper sealing and air-fuel delivery to the cylinder.

Exhaust valves in the ISM engine release hot combustion gases into the exhaust manifold. They operate in a high-temperature, high-pressure environment and are particularly prone to erosion or burning if not properly sealed. Common failure signs include:

-

White smoke at startup

-

Valve leakage

-

Engine knock or poor performance

We supply exhaust valves built from hardened materials to ensure longevity in demanding applications.

Valve Springs

Valve springs play a critical role in the timing and operation of the ISM valve train. These springs close the valves after camshaft actuation and keep them seated during combustion. When springs fatigue or fail, it can lead to valve float, misfires, or even piston-to-valve contact in worst-case scenarios.

During any top-end service, it's best practice to replace all valve springs to maintain proper spring pressure and prevent premature wear on new valves or seats.

Cylinder Head Bolts

Cylinder head bolts are designed to stretch slightly when torqued to specification, providing uniform clamping force to the head and gasket. Because they are torque-to-yield fasteners, they must be replaced whenever the cylinder head is removed.

The Cummins ISM engine uses two types of head bolts:

-

Standard main head bolts (29 per engine)

-

Supplemental small bolts (3 per engine)

Reusing old bolts may result in uneven head pressure, warping, or head gasket leaks. Always use new bolts for optimal sealing integrity and head alignment.

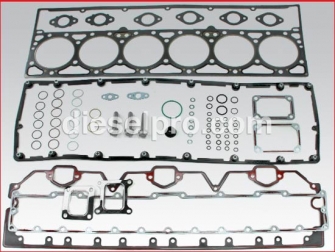

Upper Gasket Set for ISM Engines

The upper gasket set includes every gasket and seal needed to complete the installation of a new or rebuilt cylinder head. A complete set typically includes:

-

Cylinder head gasket

-

Rocker cover gasket

-

Thermostat housing gaskets

-

Valve stem seals

-

Injector seals

-

EGR gaskets (if applicable)

Using a full upper set ensures that no old or compromised gaskets are reused, reducing the chance of oil leaks or coolant contamination after reassembly.

Valve Inserts and Guides

Valve seat inserts are hardened rings pressed into the cylinder head to provide a sealing surface for intake and exhaust valves. These are wear items that can become pitted, cracked, or recessed over time.

Inserts should be replaced when resurfacing a head or when the sealing area is damaged. Installing new inserts ensures reliable valve seating and protects new valves from premature wear.

Valve guides are cylindrical sleeves that maintain the alignment of the valve stem as it opens and closes. Excessive valve guide wear can lead to oil passing into the combustion chamber, leading to:

-

Increased oil consumption

-

Blue smoke from exhaust

-

Valve chatter or instability

We carry durable valve guides engineered for the ISM’s operating profile, offering long-term reliability even in demanding environments.

Valve Guide Seals

Also called stem seals, these rubber components prevent oil from leaking into the combustion chamber along the valve stem. In turbocharged engines like the ISM, failing valve stem seals can lead to:

-

Blue smoke at startup

-

Oil fouling on injectors or plugs

-

Reduced cylinder pressure

New valve stem seals are included in the upper gasket set but are also available individually. Always replace them during a cylinder head rebuild or when changing valve guides.

Rocker Cover Gaskets and Housing Seals

The rocker cover gasket seals the upper portion of the cylinder head, preventing oil from leaking out of the valve train area. Cummins updated the design of these gaskets for improved sealing and ease of installation.

Replacing this gasket during any top-end service avoids the common problem of slow oil leaks at the top of the engine.

This gasket sits beneath the rocker cover housing and also needs to be replaced if that assembly is removed during head replacement. Like the rocker cover gasket, it ensures the oil stays within the valve train system and prevents it from leaking externally onto the block or exhaust.

Engine Temperature Switch

This thermal sensor is designed for use on Cummins ISM engines and compatible diesel platforms. It is calibrated to close at approximately 205°F and is commonly installed on marine or industrial equipment with engine protection systems.

It can trigger engine shutoff, alarms, or emergency indicators in the event of overheating, protecting your investment before serious damage occurs.

When to Replace the Cylinder Head on an ISM Engine

Signs that your ISM cylinder head may need replacement include:

-

Coolant leaking into the combustion chamber (white smoke)

-

Head gasket failure from overheating or warping

-

Cracks in the casting between valves or injector ports

-

Burned or recessed valve seats

-

Excessive oil usage with no external leaks

-

Frequent overheating even with a new radiator or thermostat

If any of the above symptoms are present, it's often more cost-effective and reliable to install a new head than to attempt further resurfacing or re-machining of a damaged unit.

Top-End Rebuild Checklist for Cummins ISM

Performing a full top-end rebuild? Here's what you'll need:

|

Component |

Function |

|

Cylinder Head (Complete) |

Base for all valve train functions |

|

Intake & Exhaust Valves |

Control air in/out of the combustion chamber |

|

Valve Springs |

Provide proper closing force for each valve |

|

Valve Seats & Guides |

Stabilize and seal valve movement |

|

Valve Stem Seals |

Prevent oil leakage into combustion |

|

Head Bolts |

Torque-to-yield fasteners that must be replaced |

|

Upper Gasket Set |

Required for reassembly and sealing |

|

Rocker Cover & Housing Gaskets |

Prevent external oil leaks |

|

Engine Temperature Switch |

Helps monitor for overheating events |

Installing new components across the entire top end ensures long-term reliability and protects your investment in a premium diesel platform like the Cummins ISM.

Applications of the Cummins ISM Engine

The ISM engine is found in a broad range of heavy-duty applications, including:

-

Over-the-road trucks (freight, tanker, and vocational use)

-

Construction equipment (cranes, loaders, and haulers)

-

Power generation systems

-

Agricultural machinery

-

Airport ground support vehicles

Because of its wide adoption, the ISM benefits from a strong aftermarket support network—but choosing precision-matched components remains critical for performance and compliance.

Why Order From Diesel Pro Power?

Trusted by over 40,000 customers worldwide, Diesel Pro Power offers:

-

Direct-fit components stored and inspected in-house

-

Same-day shipping on most ISM cylinder head parts

-

Technical support from real diesel engine experts

-

Competitive pricing without compromising on quality

We specialize in Cummins, and we’re here to help you finish your rebuild right the first time.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588