Cummins ISM Parts - Piston Kit Section

Loading...

Loading... Piston Kits & Related Components for Cummins ISM Engines

The Cummins ISM is a powerful, high-performance engine used across a wide range of heavy-duty on-highway, industrial, and vocational equipment. When it comes time to rebuild or refresh your engine, the piston kit is one of the most critical assemblies to get right. At Diesel Pro Power, we offer premium piston kits and related components specifically designed for Cummins ISM engines. Each component is manufactured to meet or exceed OEM specifications, ensuring long-lasting durability, efficient combustion, and optimal engine performance.

Complete Piston Kits for Cummins ISM

1-Piece Piston Kits for ISM Engines

For certain CPL numbers associated with marine and high-performance industrial configurations, the ISM uses a 1-piece steel or aluminum alloy piston. These pistons are forged for strength and engineered to withstand the extreme temperatures and combustion forces generated in high-duty cycle engines.

Common Features of 1-Piece Pistons:

-

Precision-machined for tight tolerances

-

Integrated combustion bowl design

-

Heat-treated alloy for improved resistance to thermal stress

-

Supplied with piston pin and retaining clips

-

Compatible with specific ISM CPLs (refer to your engine documentation)

These pistons are most frequently used in marine applications and select industrial setups that demand extreme durability and high-load endurance. Each piston kit includes the piston, pin, retaining clips, and optional pre-installed rings depending on configuration.

2-Piece Piston Kits for ISM Engines

Many ISM engines use 2-piece articulated piston designs. These kits are built with a forged steel crown and an aluminum skirt, joined together with a robust piston pin. This setup provides the best of both worlds: the strength of steel where combustion happens and the lightweight, low-friction benefits of aluminum in the skirt.

Advantages of 2-Piece Piston Construction:

-

Reduced weight without sacrificing strength

-

Lower friction for better fuel economy

-

Improved wear characteristics over time

-

Excellent performance at high engine speeds and loads

Each 2-piece piston kit comes with the piston crown, skirt, piston pin, and retainers. These kits are designed specifically for ISM engine CPL numbers and require no modifications for direct replacement.

Cylinder Liners for Cummins ISM

Each piston operates within a cylinder liner, also known as a cylinder sleeve. These liners are machined to perfection to ensure proper piston travel and combustion sealing.

Key Cylinder Liner Features:

-

Manufactured with high-grade alloy cast iron

-

Honed finish for optimal ring seating and oil retention

-

Designed for press-fit installation

-

Available in standard and oversize dimensions

It’s essential to inspect liners for scoring or taper wear during an overhaul. Diesel Pro Power offers standard-size liners as well as oversize options for engines that have been bored or honed.

Piston Ring Sets for ISM Pistons

Piston rings create the critical seal between the piston and the cylinder liner. The ISM piston ring set typically includes:

-

Compression Rings: Designed to withstand the high-pressure combustion environment and maintain cylinder compression.

-

Oil Control Rings: Regulate oil film on the liner wall and scrape excess oil back into the sump.

Ring Set Details:

-

Engineered for specific ring groove dimensions and liner wall finishes

-

Chrome or moly-faced for extended life

-

Compatible with both 1-piece and 2-piece piston kits

Each ring set is tailored for a single piston. Order as many as needed based on the number of cylinders you are rebuilding.

Piston Pins and Retainers

The piston pin (or wrist pin) connects the piston to the connecting rod. Over time, pins can wear and create excessive clearance that leads to knocking and decreased efficiency.

ISM Wrist Pin Features:

-

Case-hardened steel for long service life

-

Precision-ground surfaces for exact fitment

-

Supplied with matching retainers

We recommend replacing the wrist pin and retainers whenever installing new pistons to prevent imbalance or misalignment.

Liner Seal Rings and Shims for ISM Engines

Cylinder liners require proper sealing at the block deck and water jacket interface to prevent coolant leaks and maintain compression. Diesel Pro Power supplies the following components:

Liner Seal Rings

-

Designed for a perfect seal between the liner and engine block

-

Manufactured from high-quality elastomeric material

-

Resist high temperatures and coolant additives

Liner Shims

Used to adjust liner projection and maintain proper deck height relative to the piston. Available in various thicknesses for precise adjustment.

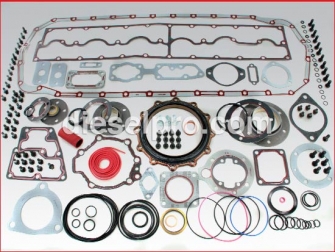

Lower Gasket Sets for ISM

While technically not part of the piston kit, the lower gasket set is required to complete any rebuild involving piston and liner installation. These sets typically include:

-

Oil pan gasket

-

Rear main seal

-

Front crank seal

-

Various O-rings and seals related to the lower engine assembly

All gaskets in the set are built for high-heat environments and tested to ensure a leak-free seal during reassembly.

Rebuilding an ISM Engine with New Pistons: What You Need to Know

Rebuilding an ISM engine is a complex job that requires precision, knowledge, and the right components. When replacing pistons, here are some critical tips to ensure success:

1. Match Your CPL

Each ISM engine has a unique CPL (Control Parts List) number. Always match your piston kit to your engine’s CPL to ensure proper fitment, compression height, combustion chamber geometry, and emissions compliance.

2. Inspect for Damage

During disassembly, inspect cylinder liners, connecting rods, and piston pins for wear or fatigue. Any scoring, cracks, or excessive clearance should prompt replacement.

3. Replace in Sets

For balance and performance, it’s recommended to replace all pistons at once—even if only one shows visible damage. Mismatched pistons can create imbalance and uneven wear.

4. Use Proper Tools

Piston ring compressors, liner installation tools, and micrometers are all essential for professional results. Diesel Pro Power also offers engine tools for Cummins ISM applications.

Frequently Replaced Components with ISM Piston Kits

When ordering piston kits, many customers also purchase the following related components:

-

Rod Bearings: To ensure smooth movement at the crankshaft journal

-

Main Bearings: For full support of the crankshaft

-

Connecting Rods: If the original rods are bent, twisted, or have damaged small ends

-

Camshaft Bushings: Often replaced during full engine overhauls

-

Oil Pumps: For engines that show signs of low oil pressure

Each of these parts contributes to the performance and longevity of your engine. Replacing them alongside pistons ensures you won’t need to revisit the engine any time soon.

Why Choose Diesel Pro Power for Cummins ISM Piston Kits?

With over 40,000 satisfied customers worldwide, Diesel Pro Power has built a reputation as a trusted provider of high-quality diesel engine parts. Here’s what sets us apart:

-

Exact Fit Guarantee: Every part is matched to your engine CPL and application

-

Fast Shipping: In-stock parts ship same day from our Florida warehouse

-

Expert Support: Our team is available to help you verify compatibility and answer technical questions

-

Global Reach: We ship to over 180 countries with reliable tracking and support

Whether you’re rebuilding an ISM for a highway fleet truck, industrial generator, or marine vessel, Diesel Pro Power has the right piston kits and components for your needs.

Need Help Identifying the Right ISM Piston Kit?

We understand that Cummins ISM engines come in many configurations. If you’re unsure which kit you need:

-

Locate your engine’s CPL number on the dataplate

-

Contact our team for assistance using our live chat or contact form

-

Use our “Verify CPL Compatibility” links next to each product

Getting the correct parts the first time will save time, money, and frustration. Let our experts help guide your rebuild with confidence.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588