Cummins KTA 19 Engine Parts - Gasket Section

Loading...

Loading... -

-

-

-

-

-

-

-

-

-

-

-

-

Detroit Diesel Striker Plate Gasket for 6V71, 6V92, 12V71 and 12V92

5145235

Gasket between blower and Striker PlatePrice: $ 15.19 -

-

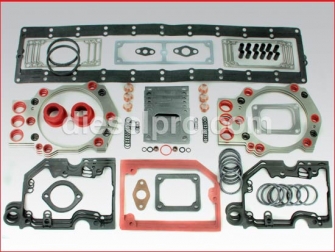

Cummins Upper Gasket Set

4024805

For turbo engines without aftercooler Three push rod holePrice: $ 590.40 -

-

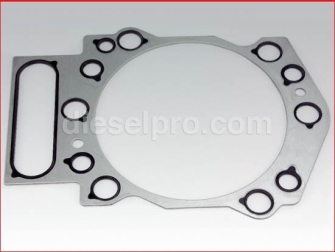

Head Gasket for Cummins KTA19, KTA38, KTA50 and QSK19

3634664

6 needed to service entire engine.Price: $ 67.12 -

-

-

-

-

-

-

-

-

Gasket Spray -High Tack Sealant (Hold & Seals Cut Gaskets)

99MA

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 25.67 -

3H Gasket Maker

3H

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 17.46 -

-

-

-

-

Gasket Maker - Ultra Blue RTV Silicone Sensor Safe

77BR

For Detroit Diesel & Cummins enginesPrice: $ 11.03 -

Gasket Sets and Gasket Components for Cummins KTA19 Engines

The Cummins KTA19 is a heavy-duty diesel engine known for its high horsepower output, exceptional durability, and robust design in marine and industrial applications. A key aspect of ensuring long-term performance is maintaining proper seals throughout the engine’s internal and external systems. Gaskets play a critical role in containing pressure, directing fluids, and preventing leaks. Whether you're performing a full in-frame rebuild or replacing worn components during scheduled maintenance, having access to the right gasket sets and individual sealing elements is essential.

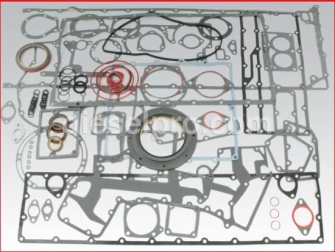

Full Gasket Sets for KTA19 Engines

Upper Gasket Sets for KTA19

Upper gasket sets are typically used during top-end rebuilds and cylinder head service. These sets include gaskets for the cylinder head, valve train, intake and exhaust manifolds, thermostat housing, rocker cover, and injector sealing.

Applications:

-

Used when removing or replacing the cylinder head.

-

Recommended when addressing coolant leaks, valve train issues, or compression loss.

-

Kits are available for both naturally aspirated and aftercooled (KTTA) configurations.

Included Components:

-

Cylinder head gaskets

-

Valve cover gaskets

-

Injector O-rings and sleeves

-

Thermostat housing gaskets

-

Rocker lever and cam follower cover gaskets

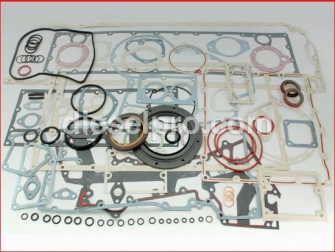

Lower Gasket Sets for KTA19

Lower gasket sets support bottom-end repairs or overhauls and contain seals for the oil pan, front and rear gear housing, timing cover, crankcase, and water/oil passages.

Applications:

-

Ideal for oil leak repairs or full in-frame rebuilds.

-

Required when overhauling pistons, liners, and crankshaft bearings.

Typical Components:

-

Oil pan gasket

-

Front and rear seal gaskets

-

Oil cooler housing and adapter gaskets

-

Gear train cover gaskets

-

Camshaft hole and hand hole cover gaskets

Cylinder Head Gaskets and Related Components

Cylinder Head Gasket for KTA19

The cylinder head gasket is the primary seal between the block and the cylinder head. It prevents combustion gases from escaping and keeps coolant and oil from mixing.

Key Details:

-

Engines like the KTA19 require six individual head gaskets—one per cylinder.

-

Designed to withstand high cylinder pressures and extreme thermal cycling.

-

Compatible with KTA19, KTA38, KTA50, and QSK19 platforms.

Rocker Lever and Housing Gaskets

These gaskets seal the valve rocker housing and rocker lever covers, ensuring that oil remains in the upper valve area and preventing contamination or leaks from breather areas.

Common Failure Symptoms:

-

Oil seepage around the valve cover area.

-

Engine top-end oil leaks after extended service intervals.

Cam Follower Cover and Hole Gaskets

Cam follower cover gaskets are responsible for sealing the access points around the cam follower bore, which must remain properly sealed to retain oil and avoid debris ingress.

Crankshaft and Camshaft Hole Cover Gaskets

Gaskets for crank and camshaft hole covers seal inspection ports used during maintenance or timing procedures. A small failure here can lead to slow oil leaks or dust intrusion in sensitive areas.

Exhaust and Intake Gasket Components

Exhaust Manifold Gaskets

These gaskets seal the exhaust manifold to the cylinder head, ensuring hot exhaust gases are properly routed to the turbocharger or stack.

Considerations:

-

Must withstand high temperatures and thermal cycling.

-

Should be replaced anytime the manifold is removed to avoid exhaust leaks or noise.

Exhaust Manifold Outlet Gasket

The outlet gasket sits between the exhaust manifold and turbo flange or pipe and requires a high-temp sealing surface. A failed gasket here may cause power loss or turbo underperformance.

Turbo Mounting Gasket

Used on water-cooled turbochargers, these gaskets provide a seal between the turbo base and the manifold or engine housing. Designed to resist oil seepage and boost pressure leaks under extreme conditions.

Fuel System Gaskets and Seals

Fuel Pump Gasket and Regulator Gasket Set

Fuel pump gaskets prevent diesel fuel from leaking where the pump mounts to the engine block or gear housing. Regulator gaskets help maintain proper fuel pressure and sealing within the regulator body.

Typical Issues Solved:

-

Fuel seepage from mounting flanges.

-

Poor injector pressure due to regulator leakage.

Injector Installation Gasket Kit

Used for high-pressure injectors on KTA19 and QSK19 engines, this kit includes all the seals needed to properly seat injectors and prevent combustion or fuel leaks around the injector body.

Oil System Gaskets

Oil Cooler Gaskets and O-Rings

The KTA19 uses several gaskets and O-rings in the oil cooler system to maintain separation between oil and coolant circuits.

Common Gaskets in This Category:

-

Oil cooler cover gasket

-

Oil cooler housing gasket

-

Oil cooler adapter gasket

-

Oil cooler O-ring

Leaks in this area can lead to oil mixing with coolant, which can severely damage engine internals.

Oil Pan Adapter Gasket

This gasket seals the oil pan adapter to the block and must be replaced during any oil pan removal or adapter maintenance. A faulty gasket here can lead to external oil drips and mess in the engine bay or bilge.

Cooling System Gaskets

Thermostat Gasket

This gasket seals the thermostat housing to the coolant passage. A leak here can cause coolant loss and inconsistent engine temperature readings.

Hand Hole Cover Gasket

Used to seal the hand hole inspection plates on the engine block, which allow access to internal components. Gaskets must be replaced when covers are removed for inspection or maintenance.

Gear Train and Timing Cover Gaskets

Gear Train Cover Gasket

This gasket provides a reliable seal between the gear train housing and the engine block, ensuring oil is contained within the front housing area and preventing debris from entering the timing gear system.

Note: Should always be replaced when performing timing gear service, gear lash inspection, or crankshaft seal maintenance.

Accessory Drive and Seal Components

Accessory Drive Oil Seal

Seals the accessory drive shaft to prevent oil leakage from the front of the engine. This seal should be inspected regularly and replaced if oil is observed around the pulley or drive housing.

Sealants and Gasket Makers for KTA19 Engines

Gasket Spray and Liquid Sealants

Gasket sprays are used to enhance the seal of paper or fiber gaskets, improving adhesion and preventing leaks. Liquid sealants, including RTV silicone, fill irregularities between metal surfaces for long-lasting seals.

Popular Options:

These compounds are commonly used in tandem with traditional gaskets during engine reassembly to ensure leak-free results under extreme operating conditions.

Gasket Service Tips for Cummins KTA19 Engines

When to Replace Gaskets

-

During scheduled top-end or in-frame rebuilds

-

Any time a component requiring a seal is removed

-

When external leaks or loss of pressure is observed

-

After overheating or mixing of fluids (oil/coolant)

Best Practices

-

Always clean mating surfaces thoroughly before installing a new gasket.

-

Use proper torque specifications to prevent over-compression or leaks.

-

Replace bolts or studs if they show signs of stretching or corrosion.

-

Use sealant only when specified by the Cummins service manual.

-

Match the gasket type (paper, metal, composite) to the component’s requirements.

Preventing Gasket Failures

-

Use OEM-quality gaskets with proper materials and construction.

-

Avoid reusing old gaskets—even if they appear undamaged.

-

Ensure the engine is operating within correct temperature and pressure ranges.

-

Address underlying causes of repeated failures (e.g., warped surfaces, improper torque).

Compatible Engines

Many of the gaskets listed are shared across multiple Cummins engine platforms. While this section focuses on the KTA19, most components—especially for the cooling, fuel, and oil systems—are also compatible with:

-

Cummins QSK19

-

Cummins KTA38

-

Cummins KTA50

Always verify compatibility before ordering if working with cross-platform components.

Summary of Key Gasket Types by System

|

System |

Common Gaskets Included |

|

Cylinder Head Area |

Head Gaskets, Rocker Cover Gaskets, Injector Seals |

|

Intake/Exhaust |

Manifold Gaskets, Turbo Gaskets, Outlet Gaskets |

|

Cooling System |

Thermostat Gasket, Oil Cooler Cover & Housing Gaskets |

|

Oil System |

Oil Pan Adapter Gasket, Oil Cooler O-rings, Adapter Gaskets |

|

Fuel System |

Fuel Pump Gasket, Regulator Gasket, Injector Install Kits |

|

Gear Train & Covers |

Gear Train Cover Gasket, Hand Hole Gasket, Cam Hole Gasket |

|

Sealants & Adhesives |

RTV, Threadlockers, Cold Weld, Non-Hardening Sealants |

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588