Cummins KTA 19 Engine Parts - Engine Water Pump Section

Loading...

Loading... -

Engine Water Pump for Cummins KTA19, QSK19 Engines

3011389

New fresh water pump — for Cummins KTA19 and QSK19 engines; OEM-quality replacement for reliable cooling performance.Price: $ 1,317.50 -

-

-

-

-

-

-

-

-

-

-

Temperature switch for Detroit Diesel, Cummins, Caterpillar engines

5146080

Closes at 205 degrees Fahrenheit.Thread size is 1/2 NPTPrice: $ 97.19 -

-

-

-

-

-

-

-

-

-

-

-

-

-

Clamp for a coolant and fuel Hose

10H

Effective Diameter Range:

Minimum 9/16", Maximum 1-1/16"

Price: $ 3.04 -

Clamp for a cooland and fuel Hose

5104592

Effective Diameter Range:

Minimum 1", Maximum 1.5"

Price: $ 4.52 -

Clamp for a coolant Hose

3412320

Effective Diameter Range:

Minimum 11/16", Maximum 1-1/4"

Price: $ 14.76 -

Clamp for a coolant Hose

4920417

Effective Diameter Range:

Minimum 13/16", Maximum 1-3/4"

Price: $ 15.78 -

Clamp for a coolant Hose

3922846

Effective Diameter Range:

Minimum 1-5/16", Maximum 2-1/4"

Price: $ 16.50 -

Clamp for a coolant Hose

3922847

Effective Diameter Range:

Minimum 1-9/16", Maximum 2-1/2"

Price: $ 16.68 -

Clamp for a coolant Hose

3922849

Effective Diameter Range:

Minimum 2-5/16", Maximum 3"

Price: $ 17.19 -

Clamp for a coolant Hose

5188036

Effective Diameter Range:

Minimum 2-7/8", Maximum 3.5"

Price: $ 5.16 -

Cummins KTA19 Fresh Water Pump & Cooling System Parts Catalog

Diesel Pro Power offers a comprehensive range of freshwater pump and cooling system components specifically designed for the Cummins KTA19 engine. Trusted by over 40,000 satisfied customers worldwide, our catalog includes the main freshwater pump, repair kits, gaskets, thermostats, coolant hoses, clamps, and related hardware to ensure your marine or industrial Cummins KTA19 engine runs at optimal temperature and reliability.

Engine Fresh Water Pump for Cummins KTA19

The freshwater pump is a key part of the Cummins KTA19 engine’s closed-loop cooling system. This centrifugal-style pump circulates coolant through the engine block and cylinder heads, absorbing heat and maintaining efficient combustion temperatures.

Key Features:

-

Designed for continuous-duty marine and industrial use

-

Precision-cast housing ensures tight tolerances and minimal wear

-

Factory-balanced impeller for long-term reliability

-

Compatible with both KTA19 and QSK19 engine configurations

-

Robust bearing support for reduced vibration and noise

Whether you’re replacing a failed water pump or performing a major cooling system service, our direct-fit pump delivers factory-grade performance and durability.

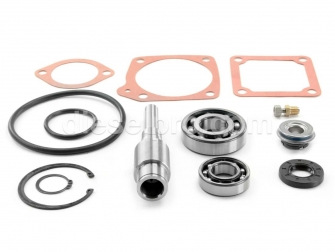

Water Pump Repair Kit for Cummins KTA19

For maintenance-minded operators, our water pump repair kit includes all essential internal components needed to overhaul your existing KTA19 pump housing. This is a cost-effective solution for reducing downtime without compromising quality.

Includes:

-

Water pump bearings

-

Impeller

-

Mechanical seals

-

Spacer sleeves

-

Gaskets and O-rings

This kit is ideal when the pump housing is in good condition but internal wear has reduced flow rate or caused coolant leakage.

Gasket for KTA19 Water Pump

A durable gasket is essential for sealing the water pump to the engine block. Our gasket is made from high-temperature resistant materials that withstand prolonged exposure to coolant and pressure without degradation.

Application Notes:

-

Designed specifically for Cummins KTA19 and QSK19 engines

-

Easy installation and compression-sealing

-

Prevents coolant seepage and air leaks

Replace the gasket any time the pump is removed to maintain a proper seal and avoid premature failure.

Thermostats for Cummins KTA19

Proper thermostat function ensures your Cummins KTA19 maintains optimal operating temperatures regardless of ambient conditions. We offer both 175°F and 180°F options to accommodate regional requirements and engine calibration.

Thermostat Options:

Both thermostat types feature stainless steel housings, wax-based actuators, and precision-engineered valve seats.

Thermostat Seals and Gaskets

To support a full thermostat replacement or service, we stock seals and gaskets that provide leak-proof installation.

Components Available:

-

Thermostat O-ring

-

Thermostat housing gasket

-

Seal rings for Detroit Diesel compatibility (if dual setups are in use)

These should be replaced with every thermostat swap to ensure reliable cooling system operation.

O-Rings for Water Connections (KTA19, KTA38, KTA50, QSK19)

These high-durability O-rings are vital for ensuring leak-free joints at coolant pipe connections and pump housings. Suitable for marine and stationary KTA series engine applications, these components resist degradation from coolant additives, high heat, and vibration.

Ideal For:

-

Water pump housing outlets

-

Thermostat housings

-

Coolant distribution manifolds

Replace these O-rings during any cooling system disassembly to avoid pressurized coolant loss.

Engine Fan Belts for Cummins KTA19

The ribbed fan belt drives essential front-end components, including the freshwater pump and fan assembly. Our belts are made from reinforced rubber with heat-resistant tensile cords for maximum life and grip under high load.

Belt Specifications:

-

Ribbed V-belt design (8 ribs)

-

Oil and abrasion resistant

-

Compatible with KTA19 belt tensioner setups

Ensure the belt is tensioned properly after installation to prevent squealing or slippage.

Radiator Cleaner for Cummins KTA19

Over time, coolant systems accumulate mineral deposits and corrosion byproducts. Our radiator cleaner is a non-corrosive solution that helps dissolve scale and rust buildup from coolant passages, radiators, and pump components.

Cleaner Benefits:

-

Restores coolant flow and heat transfer

-

Reduces risk of overheating

-

Safe for aluminum and copper cores

Use this cleaner during seasonal maintenance or when installing a new pump.

Temperature Switch for Overheat Protection

The temperature switch offers an extra layer of protection by alerting operators or triggering shutdowns when coolant temps exceed safe limits. This is especially valuable for marine applications where overheat events can damage propulsion systems.

Specifications:

-

Activates at 205°F

-

Thread size: 1/2” NPT

-

Compatible with Cummins and Detroit Diesel engines

Install this switch in-line with your alarm or safety system.

Silicone Coolant Hoses for Cummins KTA19

We offer a full range of high-temperature silicone coolant hoses in varying diameters. These hoses are ideal for high-pressure marine cooling circuits, offering enhanced flexibility and longer life compared to traditional rubber hoses.

Available Sizes (Inside Diameter):

-

3/4", 1", 1-3/4", 1-7/8", 2", 2-1/8", 2-1/4", 2-3/8", 2-1/2", 2-3/4", 3", 3-1/2", 4"

Features:

-

4-ply construction with reinforced inner lining

-

Temperature rating up to 500°F

-

Excellent resistance to coolant additives and UV exposure

All hoses are sold in 1-foot increments and can be trimmed as needed.

Hose Clamps for KTA19 Cooling System

For secure coolant and fuel line connections, our premium-grade clamps are engineered for high-pressure applications and long service life. Options range from 9/16" to over 3.5" in diameter to accommodate all hose sizes in the KTA19 system.

Common Clamp Ranges:

-

9/16"–1-1/16"

-

1"–1.5"

-

1-5/16"–2-1/4"

-

2-7/8"–3.5"

Construction Details:

-

Stainless steel band and screw

-

Smooth inner lining to prevent hose damage

-

Reusable and corrosion-resistant

Replace clamps during hose service or anytime leaks are detected under pressure.

Gauges for Monitoring Cooling System Performance

Proper monitoring is essential for marine and industrial operators running the Cummins KTA19. We offer a variety of gauges suitable for water temperature, pressure, and alarm functions:

Available Gauges:

-

Mechanical gauges (standard)

-

Mechanical with alarm triggers

-

Electrical gauges (12V and 24V compatible)

Installing these gauges gives operators early warning signs of cooling system failure and helps prevent catastrophic overheating.

Why Cooling System Maintenance Is Critical for the KTA19

The Cummins KTA19 operates under intense thermal loads, especially in marine propulsion and industrial power generation environments. Its closed-loop coolant system is responsible for regulating core engine temperatures, lubricating internal passages, and dissipating exhaust heat through the heat exchanger or radiator.

Without a properly functioning freshwater pump and associated components, the KTA19 can quickly overheat, leading to:

-

Cylinder head warping or cracking

-

Turbocharger failure

-

Head gasket blowouts

-

Reduced engine lifespan

Routine replacement of seals, hoses, thermostats, and coolant along with scheduled inspections of the water pump and impeller are key to maintaining performance and avoiding costly downtime.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588