Cummins KTA 38 Engine Parts - Gasket Section

Loading...

Loading... -

-

-

Cummins Gasket for Engine Water Pump for K38 engines

206193

Gasket for mounting flangePrice: $ 3.27 -

Cummins O-ring seal for Engine Water Pump for K38 engines

206457

O-ring seal located between water pump and inlet connectionPrice: $ 9.43 -

Cummins O-ring seal for Engine Water Pump for K38 engines

3007512

O-ring seal located in the water outletPrice: $ 12.24 -

-

-

-

-

-

-

-

-

-

-

-

-

Head Gasket for Cummins KTA19, KTA38, KTA50 and QSK19

3634664

6 needed to service entire engine.Price: $ 67.12 -

-

-

-

-

-

-

-

Gasket Spray -High Tack Sealant (Hold & Seals Cut Gaskets)

99MA

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 25.67 -

3H Gasket Maker

3H

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 17.46 -

-

-

-

-

Gasket Maker - Ultra Blue RTV Silicone Sensor Safe

77BR

For Detroit Diesel & Cummins enginesPrice: $ 11.03 -

Cummins KTA38 Engine Gasket Catalog and Technical Guide

The Cummins KTA38 is a 38-liter V12 diesel engine designed for high-performance industrial and marine applications. Operating under extreme pressure, temperature, and vibration, this engine relies heavily on a complete and properly installed gasket system. Gaskets are essential in creating oil-tight, pressure-resistant seals between mating surfaces throughout the engine—ensuring efficient combustion, fluid control, and emissions compliance.

This guide covers every major gasket and sealing solution available for the Cummins KTA38 engine platform. Whether you're doing a full overhaul or replacing a leaking cover, Diesel Pro Power provides premium aftermarket gaskets, o-rings, and sealants specifically designed for KTA38 engines.

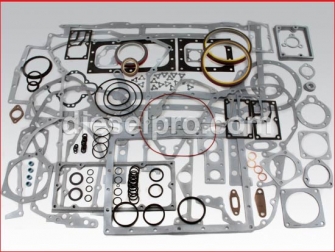

Full Gasket Sets for the KTA38 Engine

Upper Gasket Set

A Cummins KTA38 upper gasket set includes all necessary components for resealing the cylinder head and related top-end areas of the engine. This comprehensive kit is essential for in-frame rebuilds or cylinder head servicing. Common components include:

-

Cylinder head gaskets (six required for full engine service)

-

Valve cover gaskets

-

Intake and exhaust manifold gaskets

-

Thermostat housing gaskets

-

Injector seals

-

Rocker lever and cam follower cover gaskets

Designed for high heat and combustion environments, these gaskets are constructed from multi-layer steel (MLS), graphite, or composite materials to withstand expansion, vibration, and pressure cycling.

Lower Gasket Set

The lower gasket set provides all the necessary gaskets and seals for the engine’s crankcase, oil system, and timing gear housing. This set is used during full disassembly or bottom-end servicing and typically includes:

-

Oil pan gasket

-

Rear main seal

-

Front crankshaft seal

-

Gear cover gaskets (upper and lower)

-

Oil cooler seals and o-rings

-

Crankshaft and camshaft hole cover gaskets

-

Water pump mounting gasket

Each gasket in the lower set is precision cut to factory specifications and built for chemical resistance to oils, coolants, and high-temperature environments.

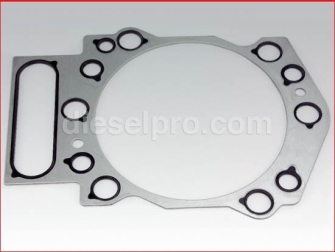

Cylinder Head Gaskets for the KTA38

The KTA38 engine requires six cylinder head gaskets to seal the combustion chambers and cooling jackets between the cylinder blocks and heads. These gaskets are multi-layered and engineered for:

-

High combustion pressures

-

Cylinder alignment

-

Optimal coolant and oil flow around the cylinder bores

Cylinder head gaskets should be replaced whenever the heads are removed. It’s also critical to inspect head bolt torque and flatness of mating surfaces during installation.

Exhaust and Turbocharger Gaskets

Exhaust Manifold Gasket

Located between the exhaust manifold and the cylinder head, this gasket ensures that high-temperature exhaust gases are channeled directly into the exhaust system. These gaskets are typically made of steel with heat-resistant sealing material. Symptoms of failure include exhaust leaks, increased engine noise, and heat damage to nearby components.

Exhaust Outlet Connection Gasket

This gasket seals the connection between the exhaust manifold and the downpipe or turbo inlet. It prevents exhaust gas leaks, improves turbo response, and ensures safe operating temperatures.

Turbo Mounting Gasket

Used to seal the turbocharger to the exhaust manifold or turbine inlet flange. For water-cooled turbos, this gasket must withstand both high exhaust heat and coolant exposure. Proper sealing at the turbo mount is crucial for preventing soot leaks and maintaining optimal turbocharger efficiency.

Water Pump and Cooling System Gaskets

Water Pump Mounting Gasket

The gasket that seals the water pump to the engine block. A proper seal ensures that coolant flow is maintained without leaks or pressure loss. These gaskets are made from coolant-resistant materials and are shaped to match the complex mounting flange of the KTA38 water pump.

Water Pump O-Ring Seals

There are several o-ring seals used on the KTA38 water pump:

-

Inlet o-ring: seals the water pump to the engine's coolant inlet

-

Outlet o-ring: seals the pump to the coolant discharge passage

Both o-rings are made from durable elastomer compounds rated for high temperatures and glycol-based coolants. These o-rings must be replaced whenever the water pump is serviced or removed.

Thermostat Gasket

This gasket seals the thermostat housing to the engine block or coolant passage. A properly functioning thermostat and a leak-free housing are essential for maintaining stable engine temperatures, especially in marine and high-load applications.

Fuel System Gaskets

Fuel Pump Mounting Gasket

This gasket seals the mechanical fuel pump to the engine block. It prevents fuel and oil leaks from the pump base and maintains consistent pressure in the fuel supply circuit.

Fuel Pump Regulator Gasket Set

This kit includes all the gaskets required to service or replace the fuel pump regulator assembly. Proper sealing here ensures consistent fuel delivery and accurate pressure control, especially important for engines running high-pressure injectors.

Oil System Gaskets

Oil Pan Gasket

The oil pan gasket seals the oil pan to the bottom of the crankcase. It is essential for maintaining oil pressure and preventing external oil leaks. This gasket is typically made from molded rubber or composite cork materials with metal core reinforcements.

Oil Pan Adapter Gasket

Used between the oil pan and the adapter housing, this gasket plays a crucial role in sealing oil passages and supporting structural rigidity. It is often replaced along with the oil pan gasket.

Oil Cooler Cover Gasket

This gasket seals the oil cooler housing to the engine block. A failure here can lead to oil leaks or coolant-oil cross-contamination. These gaskets are generally flat and made from fiber-reinforced rubber.

Oil Cooler O-Rings

These circular gaskets seal the oil cooler core and passages. They must be perfectly seated to prevent oil pressure drops or coolant infiltration. Replacing these o-rings during oil cooler service is critical for system reliability.

Rocker Lever and Camshaft Area Gaskets

Rocker Lever Cover Gasket

Seals the rocker arm housing to the top of the cylinder head. This area is prone to vibration and oil splash, so the gasket must be soft enough to conform but resilient against breakdown from oil and temperature.

Rocker Lever Housing Gasket

Located beneath the housing structure that supports the rocker arms. Replacing this gasket during top-end rebuilds ensures proper oil control and keeps contaminants out of the valvetrain.

Cam Follower Cover Gasket

Seals the cam follower or tappet access covers. This gasket is usually removed during valve lash adjustment or camshaft servicing and should be replaced afterward to ensure a secure seal.

Crankshaft and Camshaft Sealing Gaskets

Front and Rear Crankshaft Seals

While not traditional flat gaskets, front and rear crankshaft seals are part of the sealing system and are essential for containing engine oil. These seals may be complemented with:

-

Crankshaft hole cover gaskets

-

Sleeves to protect sealing surfaces

Rear main seal failures often lead to oil leaks at the flywheel area and are commonly addressed during overhauls.

Camshaft Hole Cover Gasket

Used to seal the inspection hole or service opening at the camshaft gear area. Failure here can result in slow oil leaks or contamination of the gear housing.

Gear Cover Gaskets

The timing gear cover protects and houses the front-end timing gears. It consists of:

Both are needed for full gear housing access and are commonly replaced during timing gear inspection, camshaft work, or crankshaft seal replacement. These gaskets must endure both oil exposure and vibration.

Injector Installation Gaskets

Injector installation kits often include gaskets or seals for high-pressure injectors. These gaskets ensure:

-

Leak-free fuel delivery

-

Isolation of combustion gases

-

Proper injector seating

Each injector port may include copper washers, high-temp seals, and mounting gaskets to ensure reliable performance and prevent compression blow-by.

High-Performance Gasket Makers and Sealants

In addition to pre-cut gaskets, Diesel Pro Power offers a full range of professional-grade sealants, including:

Gasket Maker – Silicone RTV

Ideal for sealing flanges without paper gaskets or enhancing gasket integrity. Available in high-temperature and sensor-safe formulas.

High-Tack Spray Gasket Adhesive

Used to hold paper gaskets in place during assembly. This tacky compound helps prevent movement or misalignment before torqueing bolts.

Non-Hardening Pliable Sealant

Used for oil-tight joints that may need disassembly in the future. This sealant stays soft and allows for easy removal.

Threadlocker – High Strength

For fasteners that pass through gasketed areas or hold pressure-sealed components in place. Prevents bolt loosening under vibration.

J-B Weld Cold-Weld Compound

Useful for emergency repairs on gasketed components where cracks or pinholes exist in mating surfaces.

Best Practices for Gasket Replacement on the KTA38

-

Clean All Mating Surfaces: Use a gasket scraper and brake cleaner to remove old material and residue.

-

Inspect Surface Flatness: Warped heads or blocks may require resurfacing.

-

Use Torque Sequences: Always follow OEM torque specs and tightening patterns.

-

Check for Cracks: Especially around coolant and oil passages before reassembly.

-

Pre-Lube Seals and O-Rings: Use engine oil or approved assembly lube to prevent dry starts.

-

Don’t Reuse Old Gaskets: Always install new gaskets and seals to avoid leaks or future failure.

Why Buy KTA38 Gaskets from Diesel Pro Power?

With more than 40,000 satisfied customers globally, Diesel Pro Power has built a reputation on quality, consistency, and unmatched support for heavy-duty diesel engines like the Cummins KTA38. When you buy your gasket sets and sealing solutions from Diesel Pro Power, you get:

-

OEM-quality aftermarket parts

-

Full inventory for complete engine coverage

-

Marine and industrial compatibility

-

Fast shipping and expert support

Common Applications for KTA38 Gaskets

-

Marine propulsion (ferries, workboats, tugs)

-

Mining haul trucks and shovels

-

Industrial power generation

-

Oilfield power units and fracturing pumps

-

Rail locomotive power units

In all these applications, gasket reliability means the difference between uptime and costly repairs.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588