Cummins KTA 50 Engine Parts - Crankshaft Section

Loading...

Loading... Crankshaft Components for Cummins KTA50 Engines

The Cummins KTA50 engine is built to deliver massive power and torque in demanding environments like marine propulsion, industrial generation, mining equipment, and offshore operations. At the core of this high-performance engine lies the crankshaft—the rotating backbone of the internal combustion process.

The crankshaft translates the linear motion of the pistons into the rotational power that drives generators, propellers, and heavy machinery. Given the massive torque output of the KTA50, its crankshaft and related components must be extremely precise, durable, and well-maintained. Diesel Pro Power offers a full selection of KTA50 crankshaft parts, including standard and oversize bearing sets, crank seals, sleeves, gaskets, and complete crankshafts.

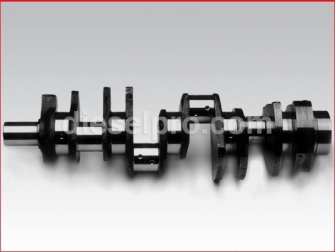

Cummins KTA50 Crankshaft – New

New Crankshaft for Cummins KTA50

Application: Factory-new crankshaft for Cummins KTA50

Type: Forged steel crankshaft

Condition: Brand new, not rebuilt or reground

This OEM-spec crankshaft is the heart of the rotating assembly. With robust bearing journals, counterweights for balance, and hardened surfaces for durability, the KTA50 crankshaft is engineered to handle the stresses of high-horsepower diesel output over thousands of service hours.

Key Features:

-

Precision-ground journals for flawless bearing contact

-

Fully counterweighted to balance 16-cylinder configurations

-

Machined oil passages to ensure consistent lubrication

When to Replace:

-

If journal surfaces are deeply scored or cracked

-

During major overhauls after failure of rod or main bearings

-

If crankshaft endplay exceeds Cummins specifications

Crankshaft Bearing Sets for KTA50 Engines

Crankshaft Shell Set – Standard Size

Use: For crankshafts with original journal dimensions

Includes: Upper and lower main bearings for full engine

Standard crankshaft bearing sets are used when the crank journals are in good condition and have not been reground. These bearings provide a precision fit between the crankshaft and engine block, allowing for proper oil film formation and load distribution.

Benefits:

-

Engineered for long service life and high-load endurance

-

Excellent oil clearance retention for stable operation

-

Reduces wear on crank journals and block saddles

Crankshaft Shell Set – Oversize 0.010"

Use: For crankshafts that have been reground 0.010" undersize

Includes: Full set of upper and lower main bearings

When crankshafts are worn or damaged, they are often reground to a smaller diameter. Oversize bearings compensate for this reduction, restoring proper clearances and pressure distribution.

Why Choose Oversize Bearings:

-

Restores factory-fit tolerances after journal machining

-

Maintains lubrication integrity

-

Protects rebuilt crankshafts from premature wear

Crankshaft Seals and Sleeves

Front Crankshaft Seal Kit

Includes: Front oil seal and mounting sleeve

Function: Prevents oil leakage at the front crankshaft opening

The front crankshaft seal is critical for preventing oil from escaping the timing gear housing. The included sleeve ensures a smooth sealing surface, especially useful when the crank surface has wear grooves.

Seal Features:

-

Resistant to high temperatures and rotating friction

-

Maintains seal integrity under vibration and shaft movement

-

Designed to fit tightly into front housing for leak-free operation

Rear Crankshaft Seal Kit

Includes: Rear main seal and mating sleeve

Function: Prevents oil leaks at the flywheel end of the crankshaft

The rear crank seal is exposed to high pressure from crankcase gases and requires a reliable seal to prevent oil from leaking past the flywheel. This kit includes a new sleeve to ensure proper contact surface and longevity.

Installation Notes:

-

Clean and inspect crank journal before installing sleeve

-

Use manufacturer-specified tools to avoid damaging the seal

-

Pre-lubricate the seal lip for dry-start protection

Rear Crankshaft Sleeve

Application: Fits over crankshaft rear journal

Purpose: Provides new sealing surface for the rear main seal

If the crankshaft journal is grooved or worn from previous seals, this sleeve restores a like-new surface, ensuring the new seal can perform optimally.

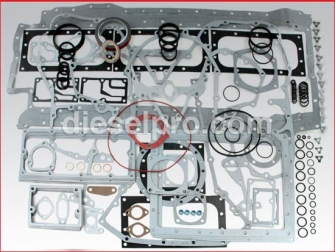

KTA50 Crankcase Gasket Sets (Upper and Lower)

Upper Gasket Set for KTA50

Includes: Head gaskets, intake and exhaust manifold gaskets, valve cover gaskets, cam follower cover gaskets, and more

Purpose: Seals the top-end of the engine

During crankshaft service, the upper gasket set is often replaced to reassemble components such as timing covers, valve train housings, and manifolds.

Highlights:

-

Resistant to high-temperature and oil saturation

-

Precision-molded sealing surfaces

-

Includes all gaskets required for upper engine assembly

Lower Gasket Set for KTA50

Includes: Oil pan gasket, main bearing seals, gear housing gaskets, and rear cover gaskets

Purpose: Seals lower portion of the engine block and crankcase

During crankshaft replacement or bottom-end overhaul, the lower gasket set ensures leak-free sealing of all mating surfaces in the crankcase area.

Features:

-

Made from durable, pressure-rated composite materials

-

Includes all critical seals for main bearings and oil circulation

-

Compatible with all Cummins KTA50 variants

Gear Cover Gaskets

Upper Gear Cover Gasket

Location: Front gear housing—upper section

Purpose: Prevents oil leakage from timing gear cover

This gasket is vital during crankshaft or camshaft service, sealing the interface between the upper front timing housing and the block.

Lower Gear Cover Gasket

Location: Front gear housing—lower section

Purpose: Seals the base of the front timing case

Both gear cover gaskets are critical for complete sealing of the crankcase and front-end gear housing, especially during crankshaft installation.

Importance of Crankshaft Maintenance in KTA50 Engines

Why the Crankshaft Is Critical

The crankshaft is responsible for:

-

Converting piston movement into rotational power

-

Synchronizing power strokes through precise phasing

-

Supporting flywheel and gear train assemblies

Given the KTA50’s massive displacement and torque output, the crankshaft endures extreme stress. A failure here can cause catastrophic engine damage, downtime, and costly repairs.

Common Signs of Crankshaft Wear or Failure

-

Low oil pressure: May be caused by worn main bearings

-

Knocking noises: Often due to bearing clearance issues

-

Excessive vibration: Can indicate journal imbalance or cracks

-

Oil leaks near the flywheel: Rear crank seal failure

If any of these symptoms appear, a crankshaft inspection and possible replacement should be considered immediately.

Installation Tips for Crankshaft Components

-

Measure bearing clearances with plastigage during installation

-

Lubricate all bearing surfaces with assembly oil before startup

-

Use proper torque sequence for main bearing caps

-

Align timing marks correctly when reinstalling crankshaft and camshaft gears

-

Replace both front and rear crankshaft seals and sleeves during a rebuild

Diesel Pro Power: Your Trusted Source for Cummins KTA50 Crankshaft Parts

With over 40,000 satisfied customers worldwide, Diesel Pro Power offers more than just replacement parts. We provide:

-

Same-day shipping on all in-stock crankshaft components

-

Expert support from technicians who understand KTA50 service requirements

-

OEM-grade quality to match or exceed Cummins performance standards

-

Secure ordering and global delivery for marine, industrial, and power gen customers

Whether you’re performing a full bottom-end overhaul or replacing just the crank seals, Diesel Pro Power has every component you need for a reliable rebuild.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588