Cummins L10 Parts - Cylinder Head Section

Loading...

Loading... Cylinder Heads & Related Components for Cummins L10 Engines

The Cummins L10 engine is a durable, mid-range diesel platform widely used in industrial machinery, commercial marine vessels, and vocational trucks. Known for its robust construction and high torque output, the L10 requires equally dependable components when it's time for a top-end overhaul or head rebuild.

At Diesel Pro Power, we supply a full range of cylinder head and valvetrain components specifically tailored to the Cummins L10 platform. From intake and exhaust valves to upper gasket sets, injector tubes, and rocker cover gaskets, we help you complete the job with confidence. With over 40,000 satisfied customers and fast worldwide shipping, we're trusted by professionals across industries.

Intake & Exhaust Valves for Cummins L10

The L10 engine uses intake and exhaust valves that differ depending on production year. Engines built before 1991 use one configuration, while those built after 1991 use updated valve designs. We offer both types to ensure compatibility regardless of your L10’s build date.

Intake Valves

Designed for optimal airflow and long-lasting durability under intense pressure and heat, our intake valves are made from high-quality alloys. Whether you're restoring a pre-1991 engine or working with a later variant, we have the correct intake valve for your needs.

Exhaust Valves

The exhaust valves play a critical role in managing combustion gases and maintaining backpressure control. Our L10 exhaust valves resist warping and pitting, even under high thermal cycling. Choose the right valve based on your engine's year of manufacture for proper fit and function.

Valve Springs for Cummins L10

Each valve in the L10 cylinder head is paired with a high-tensile valve spring to control timing and ensure a clean seal at high RPMs. These springs are engineered for both intake and exhaust operation, helping your engine maintain correct valve seating and preventing valve float under load.

Cylinder Head Bolts for L10 Engines

Replacing the cylinder head bolts is essential any time the head is removed from the block. The Cummins L10 uses a combination of primary head bolts and auxiliary bolts that must be torqued to exact specifications. We supply high-grade replacement bolts that ensure reliable head clamping force and long-lasting engine integrity.

Some bolts are shared across other Cummins engine families, such as the M11, QSM, ISL, and QSL, but we provide the exact quantity and type needed specifically for the L10.

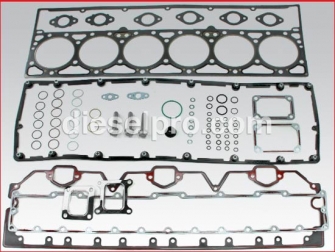

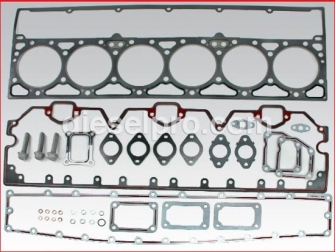

Cylinder Head Gasket & Upper Gasket Sets for Cummins L10

A successful cylinder head rebuild demands the use of a complete upper gasket set. We stock multiple versions of these kits to cover different L10 build specs and emissions variants. These kits include:

-

Cylinder head gasket

-

Intake and exhaust manifold gaskets

-

Valve cover gasket(s)

-

Rocker box gaskets

-

Injector tube O-rings

-

Valve stem seals

-

Turbocharger connection gaskets

-

Thermostat housing and coolant pipe seals

These gasket sets are designed to eliminate coolant and oil leaks, preserve compression, and protect against exhaust gas blow-by. If your L10 shares architecture with the M11 or ISM engines, we also carry hybrid kits that cover these shared sealing surfaces.

Injector Tubes & Seals for L10 Engines

The injector tubes on the L10 engine are critical for delivering fuel into the combustion chamber without leaks. Each injector tube is supported by an O-ring seal that must be replaced during reassembly to ensure combustion pressure doesn’t force fuel or gases out of the injector bore.

We supply both the tubes and the seals to make injector service seamless. These components are also compatible with certain NH855, NT855, and N14 platforms, making them a reliable cross-platform solution.

Valve Inserts (Seats) for Cummins L10

To restore proper valve seating in your cylinder head, Diesel Pro Power carries valve seat inserts for both intake and exhaust valves. These hardened inserts are press-fit into the cylinder head and provide a long-lasting surface for valve contact. We also carry oversized inserts for applications requiring head machining or valve seat resurfacing.

Whether you're doing preventative maintenance or repairing valve seat erosion, these inserts help restore original engine performance and sealing integrity.

Valve Guides & Seals

Our catalog includes valve guides for precisely aligning the intake and exhaust valves as they open and close. These guides ensure proper valve stem support and help reduce oil consumption and blow-by.

Additionally, we carry valve stem seals for both intake and exhaust valves. These seals prevent oil from entering the combustion chamber via the valve guide bore, which can otherwise lead to oil burning, fouled injectors, and emissions issues.

Rocker Cover Gaskets for Cummins L10

We supply both early and late-style rocker cover gaskets for Cummins L10 engines. These gaskets seal the top of the cylinder head, preventing oil leaks from the rocker housing. Choosing the correct style for your engine's build date ensures leak-free operation and long-term reliability.

We also offer the rocker cover housing gasket, which seals the interface between the valve cover and the rocker arm housing.

Miscellaneous Components

In addition to core rebuild components, Diesel Pro Power also offers a selection of vital small parts for completing your L10 head repair:

Heavy Hex Nuts for Rocker Arms

These specialized nuts are used to secure the rocker arm adjuster screws. Proper torque is critical to maintain valve lash and avoid top-end noise or performance loss.

Temperature Switch

This temperature sensor switch helps safeguard your engine from overheating by activating a warning system or shutdown procedure once a set temperature threshold is reached (commonly 205°F). It is suitable for Cummins, Detroit Diesel, and Caterpillar platforms and uses a standard 1/2” NPT thread for easy installation.

Trusted Parts for a Reliable Rebuild

Diesel Pro Power is committed to helping you complete a successful cylinder head overhaul or top-end service with:

-

Genuine quality—We source only reliable components built to match or exceed OEM tolerances.

-

Comprehensive kits—From valve seals to bolt kits and injector tube O-rings, you’ll find everything in one place.

-

Worldwide shipping—Parts are stocked and ready to ship, serving customers in over 200 countries.

-

40,000+ satisfied customers—Trusted globally by marine operators, powerplant technicians, and industrial service shops.

Common Cummins L10 Applications

The Cummins L10 engine is widely used in:

-

Marine propulsion and auxiliary power

-

Agricultural equipment

-

Construction machinery

-

On-highway vocational trucks

-

Industrial generators and pumps

-

Municipal and transit fleets

Our parts catalog is designed to support this broad range of environments, with components engineered to handle extreme duty cycles and challenging field conditions.

L10 Cylinder Head Rebuild Best Practices

To maximize the performance and lifespan of your engine, keep these service tips in mind:

-

Always use new head bolts during reinstallation to ensure proper torque and clamping.

-

Match your valve and gasket set to the production year of your engine—pre-1991 and post-1991 components differ.

-

Thoroughly clean the cylinder head and block mating surfaces prior to installing the new gasket.

-

Pressure-test your cylinder head to check for cracks or leaks before final assembly.

-

Use assembly lubricant on all valve components and bolts to prevent galling and premature wear.

-

Verify valve lash settings after initial run-in and again after a few hours of operation.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588