Cummins M11 Parts - Cylinder Head Section

Loading...

Loading... Cylinder Heads & Related Components for Cummins M11 Engines

Diesel Pro Power proudly stocks a comprehensive range of cylinder head components for the Cummins M11 engine platform, including the ISM and QSM variants. Whether you're performing a full top-end overhaul or simply replacing key valve train components, we carry all the major parts needed to restore compression, combustion efficiency, and durability in demanding diesel environments.

Every product is compatible with M11 engines used in marine vessels, industrial equipment, generator sets, and heavy-duty commercial applications. With over 40,000 satisfied customers worldwide, Diesel Pro Power is your reliable source for M11 engine top-end rebuild components.

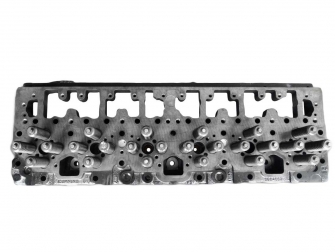

Complete Cylinder Head Assemblies for Cummins M11

Our premium new cylinder heads for Cummins M11, ISM, and QSM engines come fully assembled with valves and springs already installed. These heads are built to OEM specifications using high-grade castings and hardened valve seats. Designed for direct-fit replacement, they are ideal for customers seeking maximum uptime and reliability from their rebuild.

This head supports a wide range of electronic and mechanical M11 variants and includes the proper coolant and oil flow pathways for both industrial and marine-rated M11 configurations.

Valve Train Components for M11 / ISM / QSM Engines

Diesel Pro Power offers all major valve train components for the M11 series, allowing operators to service only the parts they need or complete a full cylinder head refresh. These include:

Intake Valves

Our intake valves for M11 engines are precision-machined to deliver smooth airflow into the combustion chamber and resist wear from high-temperature intake air and fuel mist. Designed for engines manufactured after 1991, these valves maintain a reliable seal and support optimal combustion efficiency.

Exhaust Valves

Built to withstand extreme exhaust temperatures, our M11 exhaust valves are made from high-nickel alloys and treated for superior fatigue and corrosion resistance. Suitable for extended-duty cycles in marine, genset, and vocational vehicles.

Valve Springs

We offer high-tension valve springs for both intake and exhaust sides. These springs restore correct seating pressure, reduce valve float, and are essential when replacing worn or heat-fatigued components.

Cylinder Head Hardware & Seals

A successful M11 head overhaul depends on correct hardware and proper sealing. Our inventory includes:

Cylinder Head Bolts

Cummins M11 engines require two types of bolts for securing the cylinder head to the engine block. We stock both the main clamping bolts and auxiliary bolts used in select engine designs. These fasteners are engineered to withstand the thermal and mechanical stresses of M11 operation.

Valve Guides

Valve guides center the valve stem during its travel, ensuring smooth operation and reducing oil consumption. Diesel Pro Power provides high-durability guides for both intake and exhaust sides, precisely machined to meet factory tolerances.

Valve Stem Seals

We carry both standard and high-performance valve stem seals that prevent oil leakage past the valve stem while still allowing lubrication. These are especially important for reducing oil burning and maintaining consistent engine performance.

Valve Seat Inserts

Our M11 seat inserts are available in standard and oversize formats. These inserts help dissipate heat from the valve into the head and maintain a proper valve seal even under prolonged load and high RPM conditions.

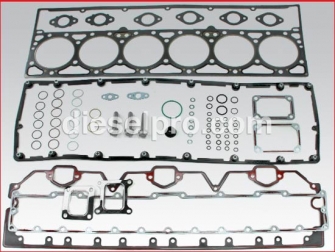

Upper Gasket Sets for Cummins M11 & ISM Engines

We offer full upper cylinder gasket sets for Cummins M11, ISM, and QSM engines. Each set includes:

-

Cylinder head gasket

-

Intake and exhaust manifold gaskets

-

Rocker cover gaskets

-

Injector tube seals

-

Valve cover gaskets

-

Thermostat housing gaskets

-

Sealing washers and O-rings

These kits ensure a complete top-end reseal with components manufactured from high-quality composite and multi-layer steel materials. All items meet or exceed OEM performance specifications.

Rocker Cover Gaskets & Housings

Our selection includes both rocker cover gaskets and rocker cover housing gaskets for later-style Cummins M11 designs. These gaskets prevent oil leaks around the top of the cylinder head and are crucial for keeping contaminants out of the valvetrain area.

Whether you're performing maintenance or replacing the head entirely, always install fresh rocker gaskets to ensure oil-tight sealing and long-term durability.

Fuel Injector Tubes & Seals

While the primary application for these components lies with the NT855 platform, some M11 rebuilders utilize shared parts such as injector tubes and O-ring seals when updating the fuel rail or injector seating. Diesel Pro Power offers a complete line of O-ring seals and copper washers to ensure proper sealing around the injector body and prevent fuel leaks or combustion blow-by.

Temperature Switches for Cummins Engines

We also stock temperature switches compatible with Cummins M11 engines used in marine or industrial generator applications. These switches are designed to trigger engine shutdown or alarms at designated operating thresholds to prevent overheating. Threaded for standard NPT connections, they’re an easy add-on during a top-end overhaul.

Common Applications for the Cummins M11

The Cummins M11 platform is widely used in both on-highway and off-highway applications. The cylinder head and top-end components featured in this section are designed for:

-

Marine propulsion and auxiliary engines

-

Power generation (standby and prime gensets)

-

Heavy-duty trucks and buses

-

Agricultural and forestry equipment

-

Oilfield service rigs and drilling platforms

These engines deliver exceptional power-to-weight ratios and are well-regarded for their fuel efficiency and durability. Our replacement cylinder head parts are suited to meet the demands of these challenging environments.

Tips for Rebuilding the Cummins M11 Cylinder Head

To ensure the long-term success of your top-end rebuild, follow these key service guidelines:

-

Replace all head bolts; never reuse old bolts that may have stretched under torque.

-

Use a calibrated torque wrench and follow the Cummins-approved tightening sequence and torque angles.

-

Inspect valve seat contact width and ensure it is within factory specifications.

-

Replace all valve seals—even if they appear undamaged—to eliminate the risk of oil leaks.

-

Always perform a pressure test on the new head before installation to ensure there are no casting flaws or porosity issues.

Why Choose Diesel Pro Power for M11 Cylinder Head Components?

-

In Stock & Ready to Ship – No delays. Get parts fast.

-

Worldwide Delivery – We serve over 200 countries.

-

Expert Technical Support – Backed by specialists who know Cummins engines inside and out.

-

Over 40,000 Satisfied Customers – Trusted by professionals across industries.

We specialize in top-end service kits and components that work the first time—and last.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588