Cummins N14 Engine Parts - Rebuild Kit Section

Loading...

Loading... Cummins N14 Engine Overhaul Kits Catalog

Overview of the Cummins N14 Engine

The Cummins N14 is one of the most dependable and powerful inline-six diesel engines ever produced. Known for its durability and wide range of industrial and commercial applications, the N14 has powered countless trucks, marine vessels, and stationary equipment since its introduction in the early 1990s. It is electronically controlled and available in various horsepower ratings, offering both fuel efficiency and power under demanding operating conditions.

The N14 evolved from the legendary Cummins Big Cam series and featured an enhanced electronic control module (ECM), advanced fuel management system, and improved emissions control. The N14's architecture includes 855 cubic inches of displacement and a heavy-duty cast iron block that supports high compression ratios, making it ideal for engine rebuilding and long service life.

Why Overhaul Your N14 Engine?

Rebuilding an N14 engine is a cost-effective alternative to replacement, especially when the engine block and head remain in usable condition. A high-quality inframe overhaul kit ensures continued reliability, reduced emissions, restored fuel economy, and optimized compression and combustion cycles. Whether you're performing preventative maintenance or reacting to a loss of power, increased oil consumption, or poor fuel mileage, a full engine rebuild helps restore your engine to peak operating condition.

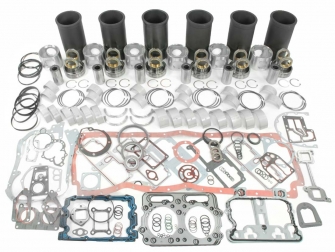

What's Included in an N14 Inframe Rebuild Kit?

Every Cummins N14 rebuild kit from Diesel Pro Power is carefully assembled to meet OEM-level specifications and fitment standards. Each inframe kit includes critical components required for a full rebuild without removing the engine from the chassis:

-

Cylinder liners (sleeves)

-

Pistons (either one-piece or two-piece depending on your application)

-

Piston rings

-

Piston pins and retainers

-

Connecting rod bearings

-

Main bearings

-

Thrust washers

-

Cylinder head gasket set

-

Oil pan gasket

-

Exhaust and intake manifold gaskets

These rebuild kits are matched to specific CPL (Control Parts List) numbers to ensure proper compatibility with your exact engine configuration.

N14 Inframe Rebuild Kits with Two-Piece Pistons

Rebuild Kit for CPL 1807, 1833, 2027, 2038, 2330, 2389, 2575, 2590

This Cummins N14 inframe rebuild kit includes two-piece pistons, which are ideal for heavy-duty, high-compression engine builds. Two-piece pistons consist of a forged steel crown and an aluminum skirt, offering better heat resistance and reduced thermal expansion. These kits are used in applications where extended uptime and power density are critical.

These piston designs allow for improved combustion under high cylinder pressures and temperatures. The advanced metallurgy also minimizes carbon build-up and wear, extending engine life.

Rebuild Kit for CPL 1809, 1844, 1852, 1896, 1921, 1924, 1987, 2003, and More

Designed for an extensive range of CPLs, this two-piece piston inframe kit supports some of the most commonly configured N14 engines in the field. The kit is ideal for long-haul trucks, marine engines, and generator sets that operate under heavy load for long periods.

The use of two-piece pistons in these rebuild kits ensures exceptional durability, particularly in applications with aggressive duty cycles. With their resistance to scuffing and thermal fatigue, these kits help reduce oil consumption and emissions while maximizing compression performance.

Supporting Components for Cummins N14 Overhauls

A successful inframe rebuild requires more than just pistons and liners. Diesel Pro Power offers a full range of auxiliary components that are compatible with the Cummins N14 engine platform and are essential to any complete overhaul.

Piston Cooling Nozzles

The N14’s piston cooling system uses oil spray nozzles mounted at the base of the cylinder. These nozzles direct engine oil toward the underside of the piston to regulate temperatures and prevent piston seizure under load. Each N14 engine requires one nozzle per cylinder.

When rebuilding your engine, it is highly recommended to replace all piston cooling nozzles to prevent clogging or wear-related failure. A compromised cooling nozzle can lead to hot spots on the piston crown, increasing the risk of ring failure or piston scuffing.

Filtration Components for N14 Rebuilds

Filters play a vital role in protecting rebuilt engines from contaminants that can cause premature wear. Diesel Pro Power provides direct-fit replacements designed to meet or exceed OEM specifications.

N14 Oil Filter

The oil filter for the Cummins N14 engine is a high-capacity, spin-on design engineered to trap harmful particles and keep your lubrication system clean. It features a durable construction to withstand high oil pressures and extended service intervals. After any rebuild, replacing the oil filter is essential to prevent debris from circulating through the new components.

Fuel Filter & Water Separator

The N14 is sensitive to fuel quality, especially in marine and industrial environments. Diesel Pro Power offers a range of fuel filters and water separators to protect your rebuilt engine from water, sediment, and microbial contamination. These filters are equipped with high-capacity media for extended operation and feature direct thread-fit designs for easy installation.

Tools and Service Aids for Cummins N14 Rebuilds

Diesel Pro Power also supplies a variety of tools and service accessories that simplify your rebuild project and help ensure professional-quality results.

Feeler Gauge for Valve Lash Adjustment

After replacing the cylinder head gasket and reinstalling the rocker assembly, precise valve lash adjustment is essential for optimal engine operation. Diesel Pro Power’s feeler gauge set spans from .002" to .025", providing accurate calibration for both intake and exhaust valves.

Correct valve lash ensures smooth idle, proper combustion, and extended valvetrain life. An incorrect gap can lead to power loss, increased fuel consumption, and even valve damage.

Piston Ring Assembly Tool

Installing new piston rings without damaging the ring lands or over-stretching the rings is crucial. A dedicated piston ring installation tool helps compress the rings uniformly, allowing for safe and accurate insertion into the cylinder liner.

Fuel Filter and Oil Filter Wrenches

These adjustable removal tools provide the right amount of grip and torque to remove stubborn filters without crushing or warping them. These are especially helpful during routine oil and fuel filter changes after a rebuild, when filter housings are tight from factory installation.

Additional Service Products for Extended Engine Life

Radiator Cleaner

Keeping your cooling system free of deposits and corrosion is essential after an inframe rebuild. Diesel Pro Power offers radiator cleaner suitable for use in Cummins N14 cooling systems. It removes rust, oil contamination, and scale buildup, allowing for improved heat transfer and coolant circulation.

Temperature Switch

Replacing the engine temperature switch during a rebuild is a proactive way to prevent future issues related to overheating or faulty temperature readings. This component closes at 205°F and is compatible with Detroit Diesel, Cummins, and Caterpillar platforms.

Compression Ratios in Cummins N14 Rebuilds

Cummins N14 rebuild kits are available with different compression ratios depending on the application and CPL. Most standard inframe kits use a compression ratio of approximately 16.0:1 to 17.0:1, depending on the piston crown design.

What Does Compression Ratio Mean?

The compression ratio refers to the volume of the combustion chamber from its largest capacity to its smallest. A higher compression ratio leads to greater thermal efficiency and more power per combustion cycle. However, it also requires high-quality components and precise timing to avoid knocking or pre-ignition.

High-compression kits are typically used in heavy-duty or performance applications, such as marine propulsion or high-torque industrial engines. Lower compression options may be selected for engines tuned for lower emissions or operating in hot climates.

CPL Matching and Compatibility

Each Cummins engine is assigned a CPL number, which indicates a specific configuration of pistons, injectors, camshaft, ECM programming, and other components. When selecting a rebuild kit, it is critical to match the CPL number of your engine to ensure proper fitment and performance.

Diesel Pro Power makes it easy to match the correct inframe kit to your engine’s CPL, eliminating the risk of mismatched pistons or liners. If you are unsure of your CPL number, it can usually be found stamped on the engine dataplate.

Why Buy Cummins N14 Rebuild Kits from Diesel Pro Power?

Diesel Pro Power has supplied high-quality diesel engine parts for over two decades, serving more than 40,000 satisfied customers worldwide. Our team specializes in helping industrial and marine diesel operators find the right parts the first time, reducing downtime and repair costs.

Benefits of Choosing Diesel Pro Power:

-

Kits assembled to meet or exceed OEM standards

-

CPL-specific compatibility

-

Fast shipping worldwide

-

Technical support from experienced diesel professionals

-

Everything you need for a complete inframe rebuild

Common Applications for the Cummins N14

The Cummins N14 powers a variety of on- and off-road vehicles, stationary equipment, and marine vessels, including:

-

Long-haul trucks (Kenworth, Peterbilt, Freightliner)

-

Construction equipment

-

Mining and oilfield applications

-

Marine propulsion and auxiliary engines

-

Power generation units

Due to its rugged build and wide power range, the N14 remains in use even after decades of service. Properly maintained and rebuilt engines continue to deliver high performance in demanding environments.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588