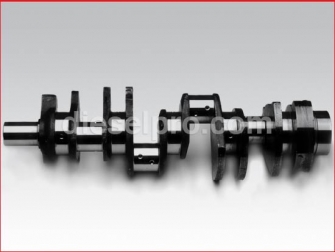

Cummins NH855 Engine Parts - Crankshaft Section

Loading...

Loading... Cummins NH855 Engine Parts – Crankshaft Section

The crankshaft is the backbone of the Cummins NH855 engine. Designed to convert the linear force of piston movement into usable rotational torque, the crankshaft must withstand extreme pressures, heat, and constant stress. In heavy-duty engines like the NH855, the crankshaft plays a vital role in reliability and long service life, especially in marine, industrial, and power generation applications.

At Diesel Pro Power, we provide a complete catalog of crankshafts and related components for the Cummins NH855, including Small Cam and Big Cam variants, as well as compatible options for NT855 and N14 engines. With over 40,000 satisfied customers worldwide, we ensure that every crankshaft component we sell meets or exceeds OEM quality standards for durability, precision, and fit.

Crankshafts for Cummins NH855 Engines

NH855 Small Cam Crankshaft

The Small Cam NH855 crankshaft is engineered specifically for early-generation NH engines. It is designed with exact tolerances to ensure smooth operation under demanding loads. Small Cam crankshafts are typically used in earlier NH855 engines found in marine vessels and stationary industrial equipment.

Key Features:

-

Heavy-duty forged steel construction for maximum strength

-

Designed to handle sustained heavy loads

-

Balanced for vibration reduction and long-term reliability

-

Precision ground journals for perfect bearing fit

This crankshaft is a direct-fit replacement for Small Cam NH855 applications, ensuring seamless integration during engine rebuilds or major repairs.

NH855 / NT855 Big Cam Crankshaft

For later-generation NH855 and NT855 engines, the Big Cam crankshaft features a reinforced design to accommodate updated engine architecture and higher performance demands. It is available in both snub-nose and bull-nose configurations, allowing technicians to select the correct design based on engine type.

Key Features:

-

Designed exclusively for Big Cam Cummins 855 engines

-

Options available for snub-nose or bull-nose styles

-

Increased torsional strength for higher horsepower applications

-

Optimized oil passage design for improved lubrication

This crankshaft is widely used in both marine and industrial NT855 engines, making it a versatile solution for fleets and operators requiring consistent performance.

Tapered Nose Crankshaft – NH855 and HT855

Certain Cummins NH855 and HT855 engines utilize a tapered nose crankshaft design. This variation is engineered for specific applications where the nose taper provides additional stability for auxiliary drive systems or accessories.

Key Features:

-

Tapered nose design for secure fitment of front-end components

-

Heavy-duty metallurgy ensures resistance to fatigue and cracking

-

Built for engines operating under constant high load conditions

Ideal for operators with specialized Cummins NH or HT855 configurations, this crankshaft provides exact fit and long-term durability.

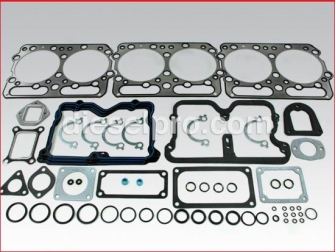

Crankshaft Bearings and Shell Sets

The crankshaft shell bearings support the crankshaft journals and ensure smooth, friction-reduced operation. Worn or undersized bearings can lead to catastrophic crankshaft damage, making replacement critical during overhauls.

Standard Size Bearing Sets

Standard crankshaft shell sets are designed for NH855, NT855, and N14 engines that have not undergone machining. These provide a direct OEM-spec fit, ensuring proper oil clearance and crankshaft support.

Oversized Bearing Sets (0.010" and 0.020")

When a crankshaft has been machined to correct wear, oversized bearing sets (0.010” or 0.020”) are required. These bearings restore proper clearances and maintain optimal oil film strength between the crankshaft and the bearing surface.

Key Benefits:

-

Designed for full engine coverage (upper and lower bearings included)

-

Manufactured from high-strength bearing alloys for wear resistance

-

Ensures consistent lubrication under high loads

Vibration Damper for Cummins NH855 & N14

The vibration damper is mounted on the crankshaft to absorb torsional vibrations and protect the engine from damaging harmonics. Without a functioning damper, the crankshaft can experience premature wear, cracking, or failure.

Key Features:

-

Heavy-duty damper specifically engineered for Cummins 855 and N14 engines

-

Large 13.54” diameter for maximum vibration absorption

-

Maintains crankshaft alignment and longevity

Replacing the vibration damper is essential during major overhauls or whenever signs of cracking, leaking fluid (in viscous dampers), or imbalance are detected.

Crankshaft Seals and Wear Sleeves

To prevent oil leakage and protect the crankshaft assembly, seals and wear sleeves are critical components. The Cummins NH855 uses front and rear seal kits that include both the seal and protective sleeves.

Front Crankshaft Seal Kit

-

Includes both seal and sleeve

-

Provides a tight, leak-free fit for the crankshaft front end

-

Essential for maintaining oil pressure and preventing contamination

Rear Crankshaft Seal Kits

Available in configurations for both dry clutch and wet clutch applications, ensuring proper compatibility with different NH855 and NT855 setups.

-

Dry Clutch Seal Kit: Designed for engines paired with dry clutch assemblies

-

Wet Clutch Seal Kit: Built for engines utilizing wet clutch systems

Rear Wear Sleeve

The rear wear sleeve provides an additional layer of protection for the crankshaft sealing surface, extending the life of both the crankshaft and the seal.

Oil Seal for Fan Hub

In addition to crankshaft-specific seals, the fan hub oil seal protects against leaks where the fan assembly interfaces with the engine. For NH855, NT855, and N14 engines, this small but crucial seal helps maintain proper lubrication and prevents oil loss from the accessory drive system.

Importance of Crankshaft Maintenance in NH855 Engines

The Cummins NH855 is a workhorse engine, often running in marine vessels, power generation units, and heavy industrial equipment for thousands of hours at a time. The crankshaft, as the primary rotating mass in the engine, must always be kept in peak condition to prevent costly downtime.

Best Practices for Crankshaft Maintenance:

-

Replace bearings during every major overhaul

-

Inspect crankshaft journals for scoring, pitting, or cracking

-

Check alignment and straightness before reinstallation

-

Always replace seals and sleeves when disassembling the crankshaft assembly

-

Ensure vibration damper integrity to prevent harmonic damage

Why Choose Diesel Pro Power for NH855 Crankshaft Parts

With decades of experience supplying Cummins engine parts, Diesel Pro Power offers unmatched expertise and reliability. We carry only high-quality new crankshafts, bearings, seals, and vibration dampers that meet strict OEM standards. Every order is backed by fast shipping, professional support, and the trust of over 40,000 satisfied customers worldwide.

When it comes to keeping your Cummins NH855 engine running at peak performance, choosing the right crankshaft components is one of the most important decisions you can make.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588