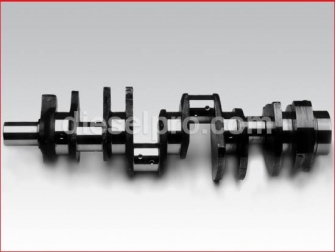

Cummins QSK 19 Engine Parts - Crankshaft Section

Loading...

Loading... Cummins QSK19 Engine Parts – Crankshaft Section

The crankshaft is the heart of the Cummins QSK19 engine’s bottom-end, converting the linear motion of the pistons into the rotational power that drives everything from marine propulsion systems to mining haul trucks and generator sets. Because the QSK19 is designed for high-horsepower, continuous-duty applications, crankshaft durability and proper bearing support are critical to engine longevity.

Diesel Pro Power supplies a complete selection of Cummins QSK19 crankshaft components, including the crankshaft itself, bearing shell sets in standard and oversize sizes, front and rear seal kits, and related gasket components. All products are selected to meet or exceed OEM specifications and support thousands of hours of industrial and marine performance.

With over 40,000 satisfied customers worldwide, Diesel Pro Power is your trusted source for heavy-duty crankshaft components shipped fast, globally.

Understanding the Cummins QSK19 Crankshaft

The crankshaft in the QSK19 engine is a forged steel component designed to handle massive internal combustion forces across six cylinders. Its long design, balanced counterweights, oil galleries, and journal tolerances are engineered for long service life, minimal vibration, and high torque output.

Key Functions:

-

Converts reciprocating piston movement into rotary motion

-

Supports smooth, balanced engine rotation

-

Distributes power to accessory drives via timing gears

-

Regulates engine inertia for smoother power delivery

Engine Platform Compatibility:

-

QSK19

-

K19

-

KTA19

-

QSK19-M (Marine variants)

-

Tier 2 and Tier 3 industrial configurations

The QSK19 crankshaft must be precisely matched to the engine’s build list (CPL number), as variations in journal size, seal type, or counterweight geometry can affect performance and compatibility.

New Crankshaft for QSK19 Engines

The QSK19 crankshaft is available as a brand-new, OEM-compatible unit. It includes machined main journals, rod journals, oiling holes, and counterweights pre-balanced to factory specs.

Advantages of a New Crankshaft:

-

No stress risers or fatigue from previous use

-

Factory-toleranced journal sizes for standard bearings

-

Clean oil galleries, no embedded debris

-

Ideal for zero-hour rebuilds or engines operating in critical environments (marine, offshore, mining)

Installation Recommendations:

-

Always measure crankcase bores for concentricity

-

Replace all crankshaft bearings during installation

-

Install with new seals and gaskets at both ends

-

Recheck torque values after initial engine run-in period

Crankshaft Bearing Shell Sets for QSK19

Each QSK19 engine uses a complete set of upper and lower crankshaft bearing shells to support the crankshaft within the engine block. These bearing shells serve as a low-friction interface that protects both the crankshaft and the crankcase bores during rotation.

Standard Size Crankshaft Bearing Set

This set includes all upper and lower bearing halves for all main journals in the engine. Standard-size bearings are used when the crankshaft journals and engine block align with factory dimensions and have not been machined or worn.

Best Used When:

-

Replacing bearings during preventive maintenance

-

Crankshaft journals show no signs of scoring or out-of-round wear

-

Micrometer measurements match Cummins factory specs

-

Oil pressure is within normal range and consistent across journals

Oversize 0.010" Crankshaft Bearing Set

This set is for engines where the crankshaft journals have been machined 0.010" undersize to correct wear, scoring, or out-of-round tolerances. Oversize bearings maintain correct oil clearance and hydrodynamic film thickness even on reground journals.

Ideal Applications:

-

Engines that experienced bearing failure

-

Rebuilds where crankshaft polishing wasn’t sufficient

-

Equipment with low oil pressure caused by excessive bearing clearance

Oversize 0.030" Crankshaft Bearing Set

This oversize bearing set is used when the crankshaft has been machined to 0.030" under its original dimension. This is typically a last machining stage before replacement becomes necessary, though the crankshaft may still be serviceable.

Important: Always verify crankshaft diameter before selecting an oversize. Installing incorrect bearing sizes will result in oil starvation, knock, or total engine failure.

Front Crankshaft Seal Kits for QSK19

The front crankshaft seal prevents engine oil from leaking out of the timing cover. It also shields the crankshaft gear from environmental debris and retains oil pressure inside the crankcase.

Front Seal Kit – Standard

Includes the front radial seal and the installation sleeve. This kit is compatible with most QSK19 engine configurations and is commonly replaced during timing gear service or in-frame overhauls.

Why Replace the Front Seal?

-

Oil seepage around the front cover

-

Low oil levels between service intervals

-

Dust accumulation on the harmonic balancer

-

Planned front gear housing removal

Front Seal Kit – With Dust Shield

Includes an added dust barrier to protect the seal lip from external contaminants. Recommended for engines operating in dusty or high-debris environments such as mines, quarries, or offshore installations.

Rear Crankshaft Seal Kits for QSK19

The rear crankshaft seal prevents oil from escaping between the flywheel housing and crankshaft flange. It is crucial for maintaining oil containment under full-load operation and for preventing leaks that could affect the clutch or transmission bell housing.

Rear Seal Kit – For Wet Housing

This kit includes the rear seal and an installation sleeve, designed for engines that use a wet rear housing configuration. In these engines, the crankcase oil level rises closer to the seal, making proper installation and seal quality even more critical.

Rear Seal Kit – Oversize for Wet Housing

This variant is used when the crankshaft rear sealing surface has minor wear or scarring and has been reconditioned. The oversize seal provides a tighter interference fit to restore leak-free performance.

Rear Seal Kit – For Dry Housing

Used on engines where the rear of the crankshaft is not in direct contact with crankcase oil (dry flywheel housing). This configuration is more common in generator sets and marine engines with external flywheel enclosures.

Installation Tip: Always use the correct installation tool or alignment sleeve to prevent seal cocking or early failure.

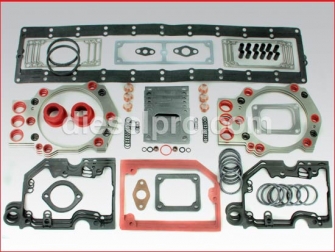

Gaskets for Crankshaft-Related Components

Upper Gasket Set (For Turbo-Aftercooled Engines)

This set includes gaskets that may be removed or disturbed during crankshaft and bottom-end service. While not exclusive to the crankshaft, this gasket set ensures complete resealing of the upper engine—including valve covers, intake manifold, and turbo mounting flanges—after a bottom-end overhaul.

Important Inclusions:

-

Cylinder head gaskets

-

Intake manifold gaskets

-

Valve cover seals

-

Turbo-to-manifold gaskets

-

Oil return gaskets

Replacing these components alongside crankshaft parts ensures a leak-free rebuild and reliable operation under thermal cycling.

Crankshaft Failure Signs and Prevention

Early detection of crankshaft wear or failure can save thousands in repair costs. Here are the most common warning signs and what causes them:

Symptoms of Crankshaft Trouble

-

Low oil pressure – caused by excessive bearing clearance

-

Metal flakes in oil analysis – indicates bearing or journal wear

-

Knocking sounds – often due to rod or main bearing failure

-

Excessive vibration – may be caused by bent crankshaft or counterweight imbalance

-

Oil leaks at seals – caused by crankshaft wobble or groove wear

Common Causes of Failure

-

Poor lubrication or oil starvation

-

Contaminated oil (metal, dirt, coolant)

-

Improper torque on main bearings

-

Misaligned crankcase bores

-

Overloading or overspeeding

-

Hydraulic lock due to coolant or fuel ingestion

When to Replace the Crankshaft

-

Journal wear beyond service limits

-

Multiple cracked or fractured counterweights

-

Previous welding or grinding repairs near oil holes

-

Reground more than 0.030" undersize

-

Vibration or balance issues after overhaul

-

Scoring due to bearing seizure

Replacing the crankshaft is more economical than risking catastrophic failure—especially in marine and power generation environments.

Installing a New QSK19 Crankshaft: Best Practices

Preparation

-

Clean crankcase bores and oil passages thoroughly

-

Inspect and align main bearing saddles

-

Use a calibrated micrometer to measure journal diameters and verify bearing size

-

Pre-lubricate journals with assembly lube or high-pressure oil

Installation

-

Install bearings in caps and saddles dry for initial fitment

-

Torque caps in sequence to Cummins specifications

-

Check end play using a dial indicator

-

Rotate the crankshaft manually to verify smoothness

-

Install seals with dedicated tools to prevent distortion

-

Prime the oil system before startup

Why Choose Diesel Pro Power for QSK19 Crankshaft Components?

-

OEM Precision: Our crankshafts and bearings meet strict Cummins tolerances

-

Fast Global Shipping: Most components ship same-day

-

Expert Support: Need help verifying oversize or seal type? We’re here to assist

-

Comprehensive Inventory: Crankshafts, bearings, seals, and gaskets—available in one place

-

Trusted Worldwide: Serving marine, mining, and industrial operators in over 180 countries

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588