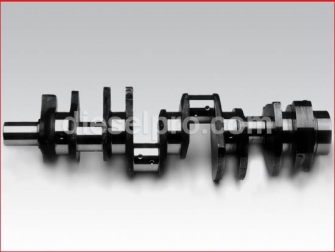

Cummins QSL Parts - Crankshaft Section

Loading...

Loading... Crankshaft & Related Components for Cummins QSL Engines

The crankshaft is the backbone of the Cummins QSL engine, responsible for transforming the reciprocating motion of the pistons into rotational power that drives the entire powertrain. In marine and industrial applications, crankshaft performance is critical to ensure smooth operation, long service life, and reliable power delivery. At Diesel Pro Power, we support over 40,000 satisfied customers worldwide with high-quality Cummins QSL crankshafts and all related components necessary for proper installation, repair, and overhaul.

The Role of the Crankshaft in Cummins QSL Engines

The QSL engine is part of Cummins’ mid-range lineup, known for its robust 8.9L displacement, high horsepower capacity, and adaptability across commercial marine, construction, and industrial platforms. The crankshaft is the central rotating component inside the block, converting piston-driven forces into usable torque.

Key characteristics of the Cummins QSL crankshaft:

-

Forged steel construction for high strength under heavy load.

-

Seven main journals supported by precision main bearings for stability.

-

Counterweights designed for optimal balance and vibration control.

-

Oil passages drilled internally to ensure consistent lubrication of connecting rod journals.

Because the QSL is often exposed to continuous-duty cycles in marine propulsion, generator sets, and construction equipment, maintaining crankshaft integrity is essential.

Complete Crankshaft Assemblies for Cummins QSL

A full crankshaft assembly provides a ready-to-install replacement when the original component shows signs of wear, cracks, or journal scoring. High-quality assemblies are precision-machined and balanced to OEM specifications to ensure smooth rotation and minimal vibration.

-

New Crankshafts – Manufactured to Cummins standards, ready for immediate installation.

-

Rebuilt/Service Crankshafts – Professionally inspected, reground, and balanced to extend service life at reduced cost.

-

Balanced and Indexed – Proper balancing prevents destructive vibrations in marine and stationary applications.

Main Bearings for Cummins QSL

Main bearings provide the critical interface between the crankshaft and the engine block, supporting the crankshaft while allowing it to rotate freely under heavy loads. Diesel Pro Power supplies both standard and oversized bearings to accommodate engine rebuilds.

-

Standard Bearings – Used in engines where journals remain within original specification.

-

Oversized Bearings – Installed after crankshaft journals have been machined undersize during reconditioning.

-

Upper and Lower Halves – Designed with oil grooves to ensure proper lubrication across all journals.

Proper bearing selection is vital for oil clearance, load distribution, and crankshaft longevity.

Connecting Rod Bearings for Cummins QSL

Connecting rod bearings fit between the crankshaft journals and connecting rods, handling the transfer of piston force to rotational energy. Like main bearings, they are available in multiple sizes.

-

Standard & Oversized Rod Bearings – Support journal repairs and precision fitting.

-

High-Durability Designs – Built to withstand constant load reversals under high-compression duty cycles.

-

Oil-Channel Engineering – Ensures consistent lubrication to reduce wear during prolonged operation.

Thrust Washers for Cummins QSL

Thrust washers control axial (end-to-end) movement of the crankshaft within the engine block. Excessive end play can cause misalignment of connecting rods, premature bearing wear, and even crankshaft damage.

-

Precision-Machined Washers – Provide consistent clearance and protect crankshaft integrity.

-

Wear-Resistant Materials – Engineered to withstand high side-loads, especially in engines operating under varying torque demands.

Crankshaft Seals for Cummins QSL

Seals prevent oil leakage at the front and rear of the crankshaft, maintaining proper lubrication and protecting against contamination.

-

Front Crankshaft Seal – Positioned behind the crank pulley, preventing oil leaks at the timing cover.

-

Rear Crankshaft Seal – Protects the flywheel end of the crankshaft; critical for preventing oil seepage into the bellhousing.

-

Seal Kits with Wear Sleeves – Available for comprehensive replacement and extended durability.

Vibration Dampers & Harmonic Balancers

High-performance QSL engines benefit from vibration dampers, which absorb torsional forces and reduce harmful crankshaft vibrations. Without them, crankshaft fatigue and eventual failure can occur.

-

OEM-Quality Dampers – Tuned specifically to Cummins QSL frequency ranges.

-

Extended Service Life – Protects crankshaft journals, bearings, and gears.

-

Replacement Interval – Often overlooked, but replacement is recommended during major overhauls.

Flywheel & Ring Gear Assemblies

The crankshaft transmits power directly to the flywheel, which stabilizes rotation and provides engagement for marine gears or industrial transmissions.

-

Balanced Flywheels – Ensure smooth torque delivery.

-

Ring Gears – Provide starter motor engagement for dependable engine cranking.

-

Matched Sets – Ensures compatibility with QSL engines in marine and industrial applications.

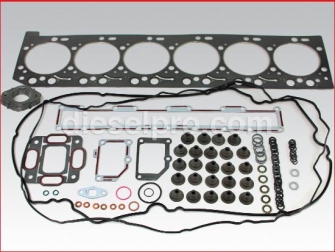

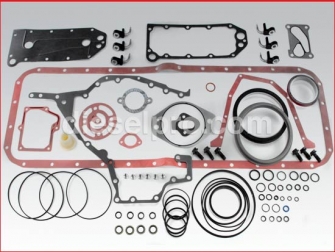

Related Gasket Sets

Whenever the crankshaft or related components are serviced, new gaskets and seals should be installed to maintain oil-tight integrity. Diesel Pro Power offers complete bottom-end gasket sets designed for Cummins QSL applications.

-

Oil Pan Gaskets

-

Front and Rear Seals

-

Bearing Cap Side Seals

-

Timing Cover Gaskets

Signs of Crankshaft & Bearing Wear in QSL Engines

Regular inspection and maintenance of crankshaft components prevent costly engine failures. Signs of potential issues include:

-

Knocking or rumbling noises at low RPM.

-

Low oil pressure due to excessive bearing clearance.

-

Metallic debris in oil filters.

-

Excessive vibration or misalignment.

-

Visible cracks or scoring on crankshaft journals.

Maintenance & Overhaul Recommendations

-

Always inspect crankshaft journals during major overhauls.

-

Replace bearings and thrust washers whenever a crankshaft is reconditioned.

-

Check alignment of main bores to prevent uneven load distribution.

-

Replace seals and dampers proactively to avoid secondary damage.

-

Use only high-quality lubricants and maintain correct oil pressure for long service life.

Why Choose Diesel Pro Power for Cummins QSL Crankshaft Parts?

With over 40,000 satisfied customers worldwide, Diesel Pro Power is a trusted supplier for Cummins QSL engines. We provide:

-

Global Shipping – Fast delivery to marine and industrial customers worldwide.

-

Expert Support – Knowledgeable team with decades of Cummins expertise.

-

High-Quality Components – Only reliable, proven parts designed to meet or exceed OEM standards.

-

Comprehensive Catalog – All crankshaft-related components available in one place.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588