Cummins QSL Parts - Cylinder Head Section

Loading...

Loading... Cylinder Heads & Related Components for Cummins QSL Engines

At Diesel Pro Power, we proudly support operators of Cummins QSL engines with top-tier replacement cylinder heads and all the related components needed for a complete and lasting top-end repair. Whether you're running a QSL9 engine in marine, industrial, or off-highway equipment, our curated selection of new cylinder heads, valve train components, gaskets, and fasteners will help you restore optimal combustion, compression, and engine performance.

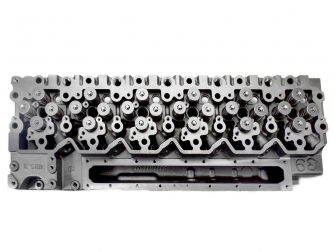

New Cylinder Head Assemblies for Cummins QSL

We offer complete, new cylinder heads for Cummins QSL engines, fully assembled with intake and exhaust valves, springs, and retainers. These are not rebuilt or remanufactured units—they are new castings built to OEM-level performance and quality. Designed to match original Cummins specifications, these heads are tested for dimensional integrity, valve sealing, and durability under heavy-duty operating conditions.

Each QSL cylinder head we carry is ideal for marine propulsion engines, standby generator sets, agricultural machines, and other equipment using the QSL9 platform. Installation is streamlined thanks to pre-installed valve gear and compatibility with OEM gaskets and bolts.

Valve Train Components for QSL Engines

To ensure long-term operation of your QSL head assembly, we stock all critical valve train components, including:

Intake Valves for QSL Engines

Our QSL intake valves are built to resist extreme thermal cycling and are precisely machined to seat cleanly in the cylinder head. These are designed for tight tolerances and optimal airflow performance—key for combustion efficiency and fuel economy.

Exhaust Valves for QSL Engines

Our high-quality exhaust valves for Cummins QSL engines are manufactured using heat-resistant alloys. These components are engineered to withstand high exhaust temperatures, making them ideal for constant-load applications like marine engines or industrial generators.

Valve Springs for QSL Engines

Valve springs maintain the seal between the valve and seat during combustion. Our intake and exhaust springs for QSL engines are rated to OEM tension specs and come with high fatigue resistance to prevent spring failure under extended load cycles.

Cylinder Head Hardware

Your QSL rebuild is only as strong as the hardware holding it together. We supply key hardware components for reliable installation:

Cylinder Head Bolts

Cummins QSL engines require multiple large-format head bolts torqued to specification. These bolts provide the necessary clamping force to seal the head to the block and prevent head gasket failure. We offer both standard and supplemental bolts to complete your installation.

Valve Seat Inserts (Intake & Exhaust)

Proper sealing and heat transfer are essential at the valve seat interface. We carry hardened steel valve seat inserts for both intake and exhaust sides, ensuring longevity and optimal seating in high-load environments.

Valve Guides

Precision valve guides ensure proper valve stem alignment during opening and closing. These are critical for maintaining compression and preventing premature valve wear. Our QSL valve guides are built to factory tolerances using heat-resistant materials for extended durability.

Valve Stem Seals

Valve stem seals control oil flow to the valve stem, preventing oil from entering the combustion chamber. We offer high-quality valve stem seals for the QSL to ensure proper lubrication without excess oil consumption or fouling.

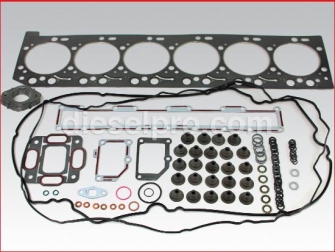

Gasket Sets for Cummins QSL Cylinder Head Rebuilds

A full top-end rebuild requires the right gaskets. We offer two complete upper gasket sets for the Cummins QSL engine, depending on the engine's fuel system configuration:

For CM554 Engines with CAPS Fuel System

This upper gasket set includes all necessary head gaskets, valve cover gaskets, intake and exhaust manifold gaskets, injector tube seals, and sealing washers needed for QSL engines equipped with the CAPS system.

For CM850 Engines with HPCR Fuel System

Engines with the HPCR system (High Pressure Common Rail) require slightly different sealing components. Our CM850-compatible upper gasket set includes all required seals to service QSL engines using electronic high-pressure injection.

Both gasket sets use materials rated for heat, pressure, and chemical resistance in diesel applications. They ensure a perfect seal between the head and engine block, as well as proper containment of fuel, coolant, and oil pathways.

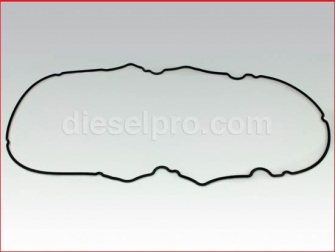

Valve Cover Gaskets for QSL Engines

Cummins QSL valve covers may vary in design—some use 5-bolt covers, while others use 8-bolt. We stock both types of valve cover gaskets to match your specific engine model.

These gaskets provide oil-tight seals between the cylinder head and rocker cover. Whether you're doing a full head replacement or resealing the cover after a valve adjustment, these gaskets prevent oil leaks and protect internal valvetrain components from contamination.

Supporting Components

For a complete rebuild or valve job, the following parts may also be required:

Rocker Cover Housing Gaskets

These gaskets seal the lower rocker housing to the top of the cylinder head and are often reused improperly, leading to leaks. We offer fresh gaskets to ensure full sealing integrity.

Temperature Sensors & Switches

We carry temperature switches rated to trigger at standard Cummins threshold temperatures. These are often used in marine and generator applications to protect against overheating and provide accurate coolant temperature monitoring.

Why Choose Diesel Pro Power for QSL Cylinder Head Parts?

-

Global Shipping: We ship QSL parts to over 200 countries with fast delivery options.

-

Expert Service: Our technical team specializes in Cummins heavy-duty engines and can help verify fitment or suggest related components.

-

In-Stock Availability: All items listed are in stock and ready to ship from our warehouse.

-

Trusted by Thousands: We’ve served over 40,000 customers across the diesel industry.

Common Applications of Cummins QSL Engines

The QSL engine is used in a wide range of marine and industrial platforms, including:

-

Marine propulsion for workboats and ferries

-

Standby and prime generator sets

-

Agricultural tractors and harvesters

-

Construction equipment like loaders and excavators

-

Oilfield power units and pressure pumpers

Our cylinder head kits and components are built to withstand the load cycles and environmental stresses seen in these applications.

Rebuild Tips for Cummins QSL Cylinder Heads

-

Always torque the head bolts using Cummins' specified sequence and torque angles.

-

Replace all valve springs during a full head job to ensure consistent performance.

-

Inspect the injector sleeves and replace if pitting, scoring, or corrosion is found.

-

Use the correct upper gasket set based on your fuel system (CAPS vs HPCR).

-

After installation, always perform a coolant pressure test and a compression check.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588