Cummins QSL Parts - Rebuild Kit Section

Loading...

Loading... Cummins QSL Engine Overhaul Kits – Complete Catalog by CPL Number

When it's time to overhaul your Cummins QSL engine, choosing the correct rebuild kit is critical for ensuring long-term performance, emissions compliance, and durability. At Diesel Pro Power, we offer a full range of Cummins QSL overhaul kits compatible with verified CPL numbers and matched to the specific piston configuration and compression ratio your engine requires.

We proudly serve over 40,000 satisfied customers worldwide, offering fast shipping, expert support, and a streamlined purchasing experience backed by decades of diesel engine expertise.

What Is a Cummins QSL Engine?

The Cummins QSL engine is a turbocharged, heavy-duty inline-six diesel engine designed for industrial, marine, and off-highway applications. It is part of Cummins' "Quantum Series," known for its advanced electronics, improved fuel efficiency, and robust power delivery. The QSL is commonly found in equipment such as mining trucks, excavators, cranes, and some marine propulsion or auxiliary applications.

The QSL typically features:

-

Displacement: 8.9 liters

-

Bore x Stroke: 114 mm x 145 mm

-

Engine Configuration: Inline-6

-

Turbocharged and aftercooled

-

Emissions systems: EGR and/or DPF in later versions

-

Power output: Typically between 250–400 horsepower depending on application and configuration

Due to the variety of CPL (Control Parts List) numbers used across different versions of the QSL engine, selecting the right rebuild kit involves identifying not just the engine model but also the CPL number, piston type, and compression ratio.

QSL Engine Overhaul Kits – Key Considerations

Before selecting your overhaul kit, consider the following:

1. CPL Compatibility

CPL numbers ensure the parts you're installing match the engine's original configuration, including piston design, fuel system, camshaft profile, and emissions calibration. Diesel Pro Power lists all supported CPL numbers for each overhaul kit to help you match your engine precisely.

2. Piston Configuration

The QSL uses two-piece articulated pistons in most versions. These pistons consist of a steel crown and an aluminum skirt, joined together via a piston pin. This design offers improved heat resistance and durability under high load—especially valuable in off-highway or severe-duty environments.

3. Compression Ratios

Two compression ratios are typically used in the QSL engine family:

-

17.0:1 Compression Ratio – This is a standard compression configuration for QSL engines intended for industrial and off-highway applications. It balances performance with fuel economy.

-

16.5:1 or Lower – Found in some versions designed for lower emissions or specific duty cycles, these pistons lower peak cylinder pressure to reduce NOx formation and accommodate EGR systems.

Compression ratio is a measure of how much the air/fuel mixture is compressed inside the cylinder before ignition. Higher ratios generally improve efficiency but require stronger components and higher-quality fuel. Always match the compression ratio of your rebuild kit to your engine's original specifications.

Available Overhaul Kits for Cummins QSL Engines

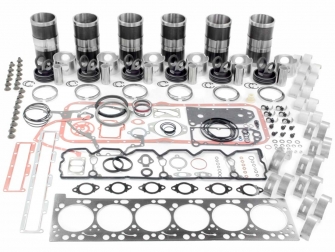

Overhaul Kit for Cummins QSL – 2-Piece Piston (Compatible with CPLs: 1096, 2701, 2736)

This rebuild kit is tailored for engines utilizing articulated two-piece pistons and includes components such as:

-

Piston assemblies (matched to your compression ratio and design)

-

Piston rings

-

Cylinder liners

-

Main bearings

-

Connecting rod bearings

-

Thrust washers

-

Full gasket set (upper and lower)

-

O-rings, seals, and wear components

This kit is engineered for operators who require reliable performance for heavy equipment, generators, or industrial vehicles where downtime must be minimized. It is especially suited to CPL 1096, 2701, and 2736—configurations typically used in industrial off-highway machines.

Compression ratio: Typically 17.0:1, depending on the specific CPL. Verify with our tech team before ordering.

Overhaul Kit for Cummins QSL – 2-Piece Piston (Compatible with CPLs: 388, 1286, 1480, 1793, 1861, 1978, 1979, 1980, 2176, 2724, 3079, 3158, 3211, 3212, 3312, 3435, 3630, 4159, 4254, 4805, 8419, 8600, 8703)

Designed for a broader range of QSL engines in diverse applications, this overhaul kit includes:

-

Premium-grade two-piece piston assemblies

-

Heat-treated piston rings

-

Cylinder liners (wet or dry, based on CPL)

-

Engine bearings (main and rod)

-

Upper and lower gasket sets

-

Valve stem seals

-

Thermostat seals, injector washers, and other wear gaskets

This rebuild kit is ideal for users rebuilding QSL engines in forestry equipment, rock crushers, mining haulers, or severe-duty construction machines. Compression ratios in these CPLs vary, but most are in the 16.7:1 to 17.0:1 range. Always consult Diesel Pro’s CPL cross-reference chart for accuracy.

Supporting Components for Cummins QSL Rebuilds

In addition to overhaul kits, you may want to replace or inspect other components during the rebuild. Diesel Pro Power offers a complete line of supporting products:

Piston Cooling Nozzles

Essential for cooling the underside of the piston crown and preventing heat damage. We stock both 1.22” and 1.73” length versions to match different CPL configurations. Always confirm your required length by referencing your engine serial number or CPL.

Crankshaft Seal Kits – Front and Rear

We offer both front and rear crank seal kits, including versions for engines with wet clutch housings or external dampers. These include the seal and sleeve to ensure a tight, leak-free crankshaft housing.

Filters (Oil, Fuel, Water Separator)

During a rebuild, it's crucial to install fresh filtration to protect your investment. We carry a complete inventory of spin-on fuel filters, oil filters, and water separators designed specifically for the QSL.

Rocker Cover Gaskets

If you're replacing cylinder heads or inspecting valves, be sure to install a new rocker cover gasket. Proper sealing ensures no oil leaks contaminate the engine or surrounding components.

Valve Adjustment Tools

Precision tools like feeler gauges and piston ring tools are available for accurate valve lash setting and piston assembly. These tools help maintain factory tolerances and prevent premature wear.

Why Diesel Pro Power?

Here’s what sets us apart when it comes to your Cummins QSL overhaul:

-

Expertise by CPL: Every kit we offer is matched to your CPL number to eliminate guesswork.

-

No Surprises: You’ll get the components you expect, guaranteed to fit your specific QSL configuration.

-

Worldwide Shipping: Fast, tracked delivery to over 180 countries, backed by logistics professionals.

-

Engineered Quality: Our kits feature OEM-grade components made to exceed factory durability standards.

Installation Notes & Best Practices

Cylinder Head Inspection

Always inspect the cylinder head for cracks, warping, or valve damage before installing an overhaul kit. Surface flatness should be within OEM tolerance, and valve guides must be tight.

Turbocharger Evaluation

Check for oil leaks, shaft play, and compressor damage. A worn turbo can cause oil ingestion or low boost pressure, both of which can jeopardize a freshly rebuilt engine.

Injector Testing

Injectors should be tested for spray pattern, pop pressure, and return flow. Dirty or worn injectors can cause imbalance across cylinders and affect combustion.

Emissions Components

On QSL engines equipped with EGR or DPF systems, always clean or replace emissions equipment as necessary. Clogged EGR coolers or DPFs can increase engine backpressure and compromise reliability.

Compatible Applications for Cummins QSL Engines

The QSL engine is used in a variety of heavy-duty equipment. Common applications include:

-

Wheel loaders and bulldozers

-

Large skid steer or track loaders

-

Rock crushers and screeners

-

Stationary power generators

-

Logging and forestry harvesters

-

Industrial compressors

-

Drilling rigs and directional boring machines

In marine contexts, the QSL may be used in gensets, propulsion systems for mid-size vessels, or auxiliary engines where high torque and long service intervals are required.

Common Signs Your QSL Engine Needs an Overhaul

-

Excessive oil consumption

-

Blue or white exhaust smoke

-

Loss of power under load

-

Hard starts, especially when cold

-

Blow-by from the crankcase breather

-

Poor fuel efficiency

-

Low compression readings on multiple cylinders

If you're experiencing any of these symptoms, performing a compression test and inspecting piston, liner, and bearing wear can confirm the need for a rebuild.

Final Thoughts

Whether you're running a Cummins QSL in a 300-horsepower mining truck or a high-torque industrial crane, restoring it with the correct overhaul kit matched to your CPL is essential. Diesel Pro Power makes it easy by listing every compatible CPL for each rebuild kit and backing it with expert customer support.

Avoid costly downtime. Restore your QSL engine with confidence—choose the overhaul kit that’s engineered for your exact configuration.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588