Cummins QSB 5.9 Parts - Fuel Pump Section

Loading...

Loading... Cummins QSB 5.9L Fuel Pump & Fuel System Components

The Cummins QSB 5.9L is one of the most reliable mid-range diesel engines in the marine and industrial world, well-regarded for its clean combustion, impressive torque, and long service life. At the core of its dependable operation is a precisely engineered fuel delivery system. The fuel pump and its related components are responsible for drawing fuel from the tank, delivering it to the injection system at the correct pressure, filtering out contaminants, and ensuring consistent, uninterrupted engine performance.

For any QSB 5.9L operator, understanding the components that make up the fuel pump system is essential — not just for maintaining performance, but also for extending the engine’s operational life and preventing costly breakdowns. This section provides a detailed overview of each part in the fuel delivery chain, from the primary transfer pump to the final fuel filter elements, pressure monitoring devices, and essential maintenance accessories.

Fuel Transfer Pumps for the Cummins QSB 5.9L

The fuel transfer pump is the first stage in the QSB 5.9L’s fuel system. Its job is to pull fuel from the tank and deliver it to the injection system at a steady, adequate pressure. A well-functioning transfer pump ensures smooth starts, prevents fuel starvation under load, and maintains optimal injector performance.

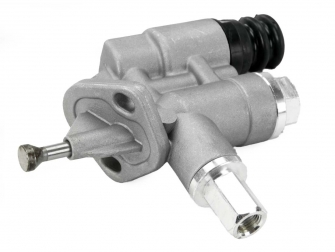

Mechanical Lever-Style Fuel Transfer Pump

The lever-style mechanical fuel transfer pump for the QSB 5.9L is designed for durability and consistent output. Using a cam-driven lever mechanism, it provides a reliable, continuous supply of diesel from the fuel tank to the high-pressure injection system. Because it is mechanically driven, it does not rely on electrical systems — making it ideal for marine and industrial environments where simplicity and mechanical reliability are prized.

Key Features:

-

Designed for the fuel flow and pressure requirements of the QSB 5.9L.

-

Robust lever-actuated design minimizes moving parts subject to wear.

-

Maintains steady fuel delivery even during engine speed changes.

-

Built with corrosion-resistant materials suitable for marine service.

-

Easy-to-service mounting location for quick replacement during scheduled maintenance.

Maintenance Tip: Check the pump periodically for external leaks and ensure the lever arm moves smoothly. Replace the pump immediately if there are signs of excessive wear or erratic fuel pressure.

Mechanical Piston-Style Fuel Transfer Pump

The piston-style fuel transfer pump offers an alternative mechanical method for moving fuel from the tank to the engine’s injection system. It uses a reciprocating piston action to draw in and push out fuel, creating a steady pressure supply.

Key Features:

-

Engineered for the QSB 5.9L’s precise pressure requirements.

-

Piston mechanism ensures consistent delivery under varying load conditions.

-

Compact, heavy-duty construction for long service life.

-

Sealed body design prevents fuel leakage and contamination ingress.

Maintenance Tip: Regularly inspect inlet and outlet fittings for tightness, and replace seals as part of routine service to avoid air intrusion into the fuel line.

Fuel Pump Gaskets & Seals for the QSB 5.9L

Gaskets in the fuel pump system are small but critical components. They form the seal between the pump and the mounting surface, preventing both fuel leaks and the intrusion of air into the system. Even the smallest leak can cause fuel starvation, loss of pressure, and difficult starting.

Fuel Transfer Pump Gasket

The fuel transfer pump gasket for the QSB 5.9L is specifically cut to match the contours of the pump base and engine mounting surface. Its high-grade material resists diesel fuel, temperature changes, and vibration.

Key Features:

-

Precision fit for the QSB 5.9L transfer pump housing.

-

Resists swelling and breakdown caused by prolonged diesel exposure.

-

Maintains seal integrity over thousands of operating hours.

-

Easy installation during pump replacement or maintenance.

Maintenance Tip: Always replace gaskets when servicing the fuel transfer pump. Reusing old gaskets can result in leaks and air intrusion.

Fuel Injection Pump Gasket

Positioned between the injection pump and its mounting point, this gasket seals in high-pressure fuel and prevents leaks that could impair engine performance or cause unsafe conditions.

Key Features:

-

Designed for the QSB 5.9L’s injection system layout.

-

High-pressure sealing capacity for dependable operation.

-

Built to maintain flexibility despite constant heat cycling.

Maintenance Tip: When installing a new gasket, clean both mating surfaces thoroughly to remove old sealant or debris before fitting the new one.

Fuel Shutoff Solenoid – 12 Volt

The fuel shutoff solenoid in the QSB 5.9L plays a crucial safety role, allowing the engine to be stopped quickly and reliably by cutting off fuel flow. The 12-volt configuration matches the electrical system of most QSB 5.9L-powered vessels and equipment.

Key Features:

-

Precision-engineered for the QSB 5.9L fuel system.

-

Quick-acting design ensures rapid shutdown in emergency situations.

-

Durable windings and plunger components resist wear.

-

Corrosion-protected housing for marine environments.

Maintenance Tip: Test the solenoid regularly by activating the shutdown system while monitoring fuel flow. Replace the solenoid if it fails to respond immediately.

Fuel Filtration for the QSB 5.9L

Clean fuel is vital to the QSB 5.9L’s performance and injector longevity. Water, dirt, and other contaminants can damage injectors, cause power loss, and lead to costly downtime. The QSB 5.9L’s filtration system consists of primary and secondary filters, often with integrated water separation.

Standard Spin-On Fuel Filter

This spin-on fuel filter traps fine particles before they can reach the injectors, ensuring consistent fuel quality and reducing wear.

Key Features:

-

Filtration media designed for optimal particle capture without restricting flow.

-

Durable canister construction withstands pressure fluctuations.

-

Compatible with the QSB 5.9L’s fuel head assembly.

Maintenance Tip: Replace the filter at intervals recommended in the Cummins service schedule, or sooner if contaminated fuel is suspected.

Fuel Filter with Integrated Water Separator

An advanced filter element that also removes water from diesel fuel, protecting the QSB 5.9L from corrosion and injector damage. This is especially important for marine environments, where fuel tanks are more susceptible to condensation.

Key Features:

-

Combines filtration and water separation in one unit.

-

Water collection bowl allows for easy draining.

-

Designed to maintain optimal fuel flow rates for the QSB 5.9L.

Maintenance Tip: Check and drain the water collection bowl regularly. Excess water in the fuel system can cause severe damage.

Racor Fuel/Water Separator Units for the QSB 5.9L

Racor separators are widely used in marine diesel applications to protect engines from contaminated fuel. They separate water from diesel before it reaches the engine’s main fuel filter.

Available Sizes for QSB 5.9L Applications:

-

500 Series – Compact, ideal for moderate flow requirements.

-

900 Series – Medium capacity for engines with higher fuel consumption.

-

1000 Series – High capacity for continuous-duty applications.

Key Features:

-

Clear collection bowl for visual inspection of water and sediment.

-

Easy element replacement without disconnecting fuel lines.

-

Marine-grade materials for corrosion resistance.

Racor Filter Elements for the QSB 5.9L

Each Racor unit requires a specific element, available in micron ratings to match your filtration strategy.

-

2 Micron (Brown Top) – Final-stage filtration to protect injectors from the smallest particles.

-

30 Micron (Red Top) – Primary-stage filtration to remove larger particles and water before fine filtration.

Maintenance Tip: Always use the correct element for your separator size and replace according to operating hours or contamination levels.

Fuel & Oil Pressure Switches for the QSB 5.9L

Pressure switches monitor vital system pressures and can trigger alarms or shutdowns when readings fall below safe limits.

Available Settings:

-

5 PSI – For low-pressure alert systems.

-

10 PSI – Common for standard monitoring.

-

20 PSI – Used in systems with higher baseline pressures.

-

27 PSI – For high-performance configurations requiring tighter monitoring.

Key Features:

-

Calibrated for accuracy within the QSB 5.9L’s operating range.

-

Rugged construction for vibration and moisture resistance.

-

Simple threaded installation with secure electrical connection.

Tools & Accessories for QSB 5.9L Fuel System Maintenance

Fuel Filter Removal Wrench

An adjustable wrench designed to grip and remove fuel filters without slipping, even in tight engine compartments.

Key Features:

-

Fits the common QSB 5.9L filter sizes.

-

Heavy-duty steel frame for long service life.

-

Textured grip for secure handling in oily or wet conditions.

Marine Engine Zinc for Fuel & Oil Coolers

In marine QSB 5.9L applications, zinc anodes protect metal cooler components from galvanic corrosion, extending service life.

Key Features:

-

Brass plug body with threaded design for easy installation.

-

High-purity zinc core for effective corrosion prevention.

-

Specifically sized for the QSB 5.9L’s cooler housings.

Ongoing Maintenance Advice for QSB 5.9L Fuel Systems:

-

Follow a strict filter change schedule to maintain fuel quality.

-

Monitor fuel pressure readings and investigate sudden changes immediately.

-

Inspect hoses and clamps during every service interval.

-

Drain water separators frequently in marine environments.

-

Test shutoff solenoids as part of safety system checks.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588