Cummins QSB 5.9 Parts - Gasket Section

Loading...

Loading... -

-

-

-

-

-

-

-

-

-

-

-

-

762 Hi-Temperature jointing compound for Detroit Diesel and Cummins turbos

762

225 gm tube - Temp range 550C to 760CPrice: $ 188.19 -

-

-

-

-

Gasket Spray -High Tack Sealant (Hold & Seals Cut Gaskets)

99MA

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 25.67 -

3H Gasket Maker

3H

For Detroit Diesel & Cummins engines. Available for ground shipping only in USA and CanadaPrice: $ 17.46 -

-

-

-

-

Gasket Maker - Ultra Blue RTV Silicone Sensor Safe

77BR

For Detroit Diesel & Cummins enginesPrice: $ 11.03 -

Cummins QSB 5.9 Gasket Section – Marine & Industrial Applications

The Cummins QSB 5.9 is a high-performance diesel engine used extensively in both marine and industrial settings. One of the key factors in keeping this engine operating at peak efficiency is the integrity of its gasket and sealing systems. From preventing coolant leaks to ensuring proper combustion chamber compression, the right gaskets are essential for engine reliability, performance, and longevity.

At Diesel Pro Power, we offer a complete selection of gaskets, seals, O-rings, and sealing compounds designed specifically for the Cummins QSB 5.9 platform. Our inventory covers everything from full upper and lower gasket sets to specialized seals for the oil cooler, turbocharger, water pump, and fuel system.

Importance of Quality Gaskets in Cummins QSB 5.9 Engines

Gaskets perform a vital function by sealing surfaces between engine components to prevent leaks of oil, coolant, fuel, and combustion gases. In a Cummins QSB 5.9, which is designed for high torque output and continuous duty, gasket performance directly impacts:

-

Compression retention in the cylinders.

-

Cooling system efficiency by preventing coolant loss.

-

Oil circulation integrity by keeping lubrication channels sealed.

-

Turbocharging efficiency by eliminating boost leaks.

-

Prevention of cross-contamination between oil and coolant passages.

Complete Gasket Solutions for Cummins QSB 5.9

Whether you are conducting a full engine overhaul, replacing a single leaking component, or performing preventative maintenance, our Cummins QSB 5.9 gasket catalog has the right solution.

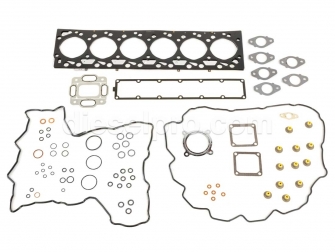

Upper Gasket Set for Cummins QSB 5.9

The upper gasket set is used when performing top-end repairs, such as cylinder head removal. It typically includes:

-

Cylinder head gasket

-

Valve cover gaskets

-

Intake and exhaust manifold gaskets

-

Injector seals

-

Miscellaneous O-rings for top-end components

This set is ideal for resolving compression loss, coolant seepage into combustion chambers, or oil leaks from upper engine components.

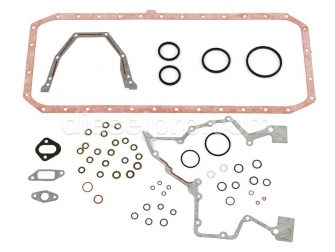

Lower Gasket Set for Cummins QSB 5.9

The lower gasket set is used for bottom-end servicing. It contains:

-

Oil pan gasket

-

Front and rear crankshaft seals

-

Timing cover gasket

-

Oil pump gaskets

-

Water pump gaskets

These gaskets are crucial for maintaining oil pressure and preventing leaks in the lower half of the engine.

Individual Gaskets and Seals for QSB 5.9

The marine water pump O-ring seals the inlet and outlet ports of the raw water pump, ensuring efficient cooling water transfer. Each QSB 5.9 requires two of these O-rings, and they should be replaced any time the pump is serviced.

Prevents oil leakage from the sump. This gasket should be replaced whenever the oil pan is removed, ensuring a proper seal against high-vibration conditions common in marine use.

Seals the oil pick-up tube to the engine block, preventing air from entering the oil system—a critical factor in maintaining proper oil pressure.

Ensures an airtight seal on the intake manifold cover to maintain correct air pressure and flow into the combustion chambers.

Maintains a leak-free seal in the aftercooler, helping to keep intake air temperatures within safe operating limits.

Prevents oil leaks from the top of the cylinder head. Designed to withstand high temperatures and oil exposure over extended service intervals.

Fuel Transfer Pump and Fuel Injection Pump Gaskets

These gaskets prevent fuel leaks at the pump mounting surfaces, ensuring consistent fuel delivery and preventing contamination.

Provide a tight seal for the oil cooler cover, preventing oil leakage and ensuring the cooler operates at maximum efficiency.

Seals the turbocharger oil drain line to the engine block, preventing oil seepage into the bilge or machinery spaces.

A precision seal that ensures no coolant loss from the water pump assembly.

Prevents coolant leaks around the thermostat housing and helps maintain proper engine operating temperature.

Gasket Makers, Sealants, and Compounds for Cummins QSB 5.9

In addition to pre-formed gaskets and O-rings, certain repairs may require liquid gasket makers or sealing compoundsto ensure a perfect seal. We stock a full range of high-performance options compatible with the QSB 5.9.

-

Hi-Temperature Jointing Compound – Withstands up to 760°C, ideal for turbocharger and exhaust system sealing.

-

Gasket Spray – High Tack Sealant – Secures paper or composite gaskets in place during installation.

-

Liquid Gasket Maker – For flexible sealing where parts may experience vibration or movement.

-

Threadlocker – High Strength Red – Locks threaded fasteners against vibration loosening.

-

Silicone Sensor Safe Gasket Maker – Ideal for components with sensitive electronics nearby.

-

J-B Weld Cold Weld – For emergency or temporary repairs on metal surfaces.

-

High-Temp RTV Silicone – Suitable for areas exposed to extreme heat.

-

Ultra Blue RTV Silicone – A versatile, sensor-safe sealing option.

-

Non-Hardening Pliable Sealant – Remains flexible for long-term vibration resistance.

Maintenance Tips for Cummins QSB 5.9 Gaskets

-

Always Replace Gaskets During Component Removal – Even if the old gasket looks intact, reusing it can lead to leaks.

-

Inspect Sealing Surfaces – Clean and smooth surfaces help gaskets seat correctly and last longer.

-

Use Torque Specifications – Over-tightening can crush gaskets, while under-tightening can cause leaks.

-

Choose Marine-Grade Sealants – If your QSB 5.9 operates in saltwater conditions, corrosion-resistant sealants are essential.

-

Replace O-Rings with OEM-Quality Parts – Especially important for high-pressure systems like fuel and cooling circuits.

Why Buy Your QSB 5.9 Gaskets from Diesel Pro Power?

-

Global Shipping – Fast delivery worldwide, ensuring minimal downtime.

-

40,000+ Satisfied Customers – Trusted by commercial fleets, shipyards, and industrial operators.

-

Extensive Inventory – Everything from full gasket kits to the smallest O-ring.

-

Marine & Industrial Specialists – We focus on non-automotive diesel applications, so our parts fit the right engines for the right jobs.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588