Cummins QSB 5.9 Parts - Oil Section

Loading...

Loading... -

Cummins Oil Pump

4939587

For engines with a front gear train.

Pinions have 23/24 Helix Teeth.For engines with CPL#s 591, 599, 714, 721, 742, 831, 1279, 1288 ,1519, 1522, 1523, 1524, 1551, 1816, 1889, 1914, 1948, 1961, 1962, 1975, 2014, 2063, 2071, 2122, 2205, 2208, 2242, 2243, 2292, 2347, 2372, 2373, 2446, 2447, 2486, 2530, 2686, 2891, 2893, 8208, 8217, 8236, 8266, 8267, 8304, 8305, 8306, 8444

Price: $ 104.45 -

Cummins Oil Pump

4939588

For engines with a rear gear train.

Pinions have 22/24 Straight Teeth.For Engines With CPL#s 426, 427, 656, 1388, 1860, 2605, 2676, 2715, 3070, 3071, 3072, 3094, 3095, 3277, 3335, 3336, 3632, 3858, 3861, 3870, 3934, 4606, 4608, 4577, 4699, 4804, 8464, 8466, 8610, 8611, 8732

Price: $ 110.98 -

Cummins Oil Pump

4897481

For engines with a front gear train.

Pinions have 22/24 Straight Teeth.For engines with CPL#s 0742, 8206

Price: $ 104.45 -

-

-

-

-

-

-

Cummins Oil Filter

3908616

Spin-on type. 3.66" outside diameter, 5.35" height, thread size: 1-16 UNPrice: $ 25.74 -

Cummins Oil Filter

3937743

Spin-on type, 3.66" outside diameter, 6.95" height, thread size: 1-16 UNPrice: $ 32.80 -

Oil Filter Removal Wrench for Detroit Diesel, Caterpillar & Cummins

2321

4-21/32" to 5-5/32"Price: $ 63.29 -

-

-

-

Zinc for Cummins Marine Engine Fuel and Oil Coolers

3957921

Brass plug NPT 3/8”, zinc length 1”Price: $ 20.77 -

-

Fuel & Oil Pressure Switch - 10 PSI Make/Break

23520024

10 PSI make/break with 1/8 nptPrice: $ 99.79 -

Fuel & Oil Pressure Switch - 20 PSI Make/Break

23520025

20 PSI make, break with 1/8 nptPrice: $ 96.44 -

Fuel & Oil Pressure Switch - 27 PSI Make/Break

23511819

27 PSI make/break with 1/8 nptPrice: $ 81.10 -

Oil System Components for Cummins QSB 5.9L Engines

The oil system in the Cummins QSB 5.9L engine is critical for proper lubrication, cooling, and protection of internal components. A healthy oil pump, quality filtration, and effective oil cooling all contribute to extending engine life, maintaining performance, and preventing costly repairs. Diesel Pro Power offers a full selection of oil pumps, oil coolers, gaskets, oil filters, and pressure monitoring devices for the QSB 5.9L, supporting both front and rear gear train configurations.

Whether your engine is powering a marine vessel, industrial generator, or heavy equipment, the right oil system components keep it running efficiently under heavy loads and demanding operating conditions.

Cummins QSB 5.9L Oil Pumps

The oil pump is the heart of the lubrication system, drawing oil from the sump and delivering it under pressure to the engine’s bearings, camshaft, valve train, and other moving parts. The QSB 5.9L can be configured with either a front gear train or a rear gear train, and the oil pump selection must match the specific CPL (Control Parts List) configuration.

Front gear train configurations in the QSB 5.9L use precision-engineered pinions with either 23/24 helix teeth or 22/24 straight teeth, depending on the CPL designation. Helical gear designs reduce noise and deliver smoother power transfer, while straight tooth versions are robust and simple to maintain. Both types are engineered for optimal oil pressure delivery across all engine speeds.

Applications for front gear train pumps often include marine propulsion systems, generator sets, and industrial machinery where consistent lubrication is required even under constant high loads.

Rear gear train configurations use oil pumps with 22/24 straight teeth, designed for high durability and easy serviceability. These pumps are common in certain marine configurations where the gear train location provides easier maintenance access in confined engine rooms.

Rear gear train oil pumps maintain strong lubrication flow even during extended idling or varying RPM ranges, making them well-suited for tugboats, fishing vessels, and industrial applications with fluctuating load demands.

Oil Pump Performance and Maintenance

Proper oil pump function is essential to:

-

Maintain stable oil pressure across varying temperatures and loads.

-

Prevent metal-to-metal contact that can cause wear or seizure.

-

Support turbocharger lubrication, ensuring longevity and efficiency.

-

Circulate oil through coolers and filters for optimal thermal management.

Maintenance Tip: Always inspect for signs of wear such as scoring on pump gears or housings. Replace the pump if oil pressure readings drop below manufacturer specifications or if excessive gear lash is observed.

Oil Filtration for Cummins QSB 5.9L Engines

Clean oil is essential for preventing abrasive particles from damaging bearings, piston rings, and valve train components. The QSB 5.9L uses spin-on style oil filters available in different lengths to suit application requirements.

-

Standard Spin-On Filters – Designed for efficient filtration with minimal flow restriction.

-

Extended-Length Filters – Provide additional media surface area for extended service intervals, ideal for long-running marine and generator applications.

Filtration Best Practice: Always pre-fill the oil filter with clean engine oil before installation to reduce the time the engine runs without full oil pressure on startup.

Oil Cooling Components

Heat is one of the most damaging forces in any diesel engine. The QSB 5.9L uses oil coolers to regulate lubricant temperature, preventing viscosity breakdown and thermal damage to components.

Plate-Type Oil Coolers

Most QSB 5.9L engines use multi-plate oil coolers for maximum heat dissipation. The number of plates can vary depending on the specific build and cooling requirements. These coolers are built from corrosion-resistant materials to withstand marine environments and extended service life.

Marine-Specific Cooling Considerations

In marine applications, oil coolers may be integrated with seawater cooling circuits. Sacrificial zinc anodes are often installed to protect cooler internals from galvanic corrosion. Replacing these anodes regularly is essential to avoid cooler damage.

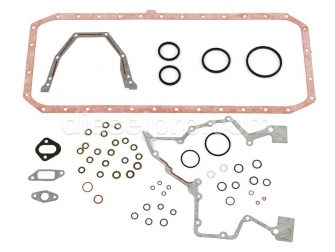

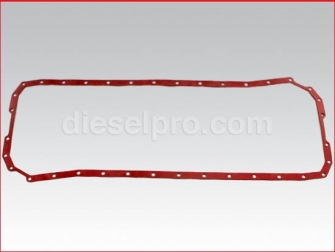

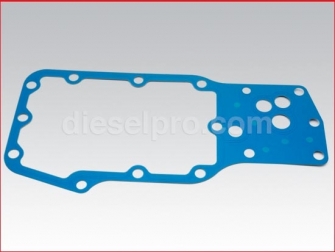

Oil System Gaskets & Seals

The oil system relies on high-quality gaskets and seals to maintain pressure and prevent leaks.

-

Oil Pan Gaskets – Seal the pan to the crankcase, preventing leaks at the lowest point of the lubrication system.

-

Oil Pick-Up Tube Gaskets – Ensure the pump can draw oil without introducing air, which would cause cavitation.

-

Oil Cooler Cover Gaskets – Provide a secure seal between the cooler housing and engine block.

-

Oil Cooler Core Gaskets – Metal or composite gaskets that seal the cooler core to the housing.

Maintenance Tip: Always replace gaskets during servicing to ensure proper sealing. Reusing old gaskets can lead to leaks, pressure loss, and contamination.

Oil Pressure Monitoring

Oil pressure is the key indicator of engine lubrication health. Diesel Pro Power offers a range of mechanical and electric oil pressure gauges along with pressure switches that can trigger alarms or shutdown systems when pressure falls below safe limits.

Common Oil Pressure Switch Ratings

-

5 PSI Make/Break – For low-speed or idle protection.

-

10 PSI Make/Break – Standard safety threshold for many marine engines.

-

20 PSI Make/Break – Higher protection level for engines under sustained load.

-

27 PSI Make/Break – Used in applications requiring maximum lubrication assurance.

Best Practice: Pair an oil pressure switch with an audible alarm in marine applications to alert the operator immediately to lubrication issues.

Oil System Service Tools

Proper service requires the right tools. For oil filter removal, an adjustable oil filter wrench compatible with 4-21/32" to 5-5/32" filters ensures safe and efficient filter changes without damaging the housing.

Summary

The Cummins QSB 5.9L oil system is a carefully engineered combination of pumps, coolers, filtration, sealing components, and monitoring devices. Whether your engine is installed in a yacht, commercial fishing vessel, industrial generator, or construction machine, these components work together to ensure optimal lubrication and temperature control.

Regular inspection, timely replacement, and proper maintenance of these parts are essential to preserving the engine’s longevity, efficiency, and reliability.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588