Cummins QSB 7.0 Parts - Marine Water Pump Section

Loading...

Loading... Cummins QSB 7.0 Marine Water Pump & Cooling System Parts

The Cummins QSB 7.0 engine is a powerful, electronically controlled marine diesel platform commonly used in commercial vessels, yachts, patrol craft, and auxiliary equipment. Built for performance and durability, the QSB 7.0 relies on a raw water cooling system to regulate engine temperature and ensure optimal combustion efficiency.

At Diesel Pro Power, we offer high-quality, marine-grade raw water pump components and accessories engineered specifically for the Cummins QSB 7.0 engine. This section includes the gear-driven sea water pump, impeller servicing tools, and maintenance insights to help keep your cooling system operating efficiently in harsh saltwater environments.

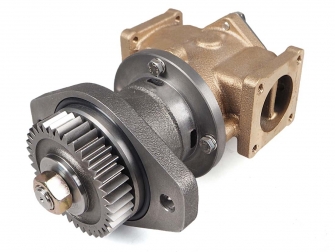

Gear-Driven Raw Water Pump for Cummins QSB 7.0 Marine Engines

Heavy-Duty Marine Water Pump with Gear and Spline Drive

Designed exclusively for the Cummins QSB Series marine engines, this sea water pump is built to exceed OEM performance standards. With a factory-installed gear and spline drive shaft, this pump is ready to drop in for straightforward installation and reliable operation.

Features:

-

Pump Type: Gear-driven raw water pump with integrated marine-grade housing

-

Drive Interface: Spline drive—optimized for torsional transfer and wear resistance

-

Construction: Corrosion-resistant bronze and stainless internal hardware

-

Fitment: Engineered to match the mounting flange and gear interface of Cummins QSB 7.0 marine platforms

This pump delivers consistent water flow at low and high RPMs, ensuring proper heat transfer even during full-throttle operation or prolonged idling. The gear-driven design reduces vibration and enables more precise synchronization with engine timing.

Applications:

-

Workboats and patrol vessels powered by QSB 7.0 engines

-

Mid-size commercial fishing craft

-

Marine generator sets

-

Custom marine retrofits and engine repowers

For optimal performance, always verify pump alignment and spline lubrication during installation.

Why the QSB 7.0 Requires a Reliable Raw Water Pump

In marine environments, saltwater is used to extract heat from the engine's closed-loop coolant via a heat exchanger. The raw water pump is the component that makes this heat exchange possible. A malfunctioning or worn pump can lead to overheating, reduced engine performance, or catastrophic failure.

Benefits of a properly functioning QSB 7.0 raw water pump:

-

Maintains consistent engine operating temperature

-

Reduces risk of head gasket failure due to overheating

-

Prevents corrosion of cylinder liners and other cooling circuit components

-

Helps maintain turbocharger temperature balance

When replacing a marine water pump, it is essential to also inspect related components such as impellers, gaskets, heat exchanger surfaces, and coolant flow pathways.

Supporting Tools: Impeller Puller for Cummins QSB 7.0 Water Pump

Universal Marine Impeller Puller Tool

Removing a marine impeller can be a frustrating process without the right equipment. The impeller puller tool is specially designed to extract impellers from QSB 7.0 and other Cummins pump housings without damaging the blades or scarring the pump shaft.

Tool Features:

-

Fits: QSB, QSC, and other mid-range Cummins marine engines

-

Function: Provides even pull pressure across all impeller blades

-

Use Case: Ideal for removing rubber or neoprene marine impellers that have hardened due to age or heat

-

Material: Heavy-duty stainless steel for marine shop environments

This tool is recommended for every marine technician's kit. It helps ensure clean removal, reduces the risk of tearing impeller vanes, and speeds up pump servicing dramatically.

What to Inspect When Servicing the QSB 7.0 Raw Water Pump

To ensure long service life and maximum uptime on your Cummins QSB 7.0 marine engine, inspect and maintain the following components during each scheduled water pump service:

1. Impeller Blades

-

Check for cracks, splits, or missing blades

-

Hardened impeller material indicates overheating or extended service interval

2. Pump Shaft and Bearings

-

Look for corrosion, pitting, or wobble

-

Any shaft movement can cause seal failure and internal leakage

3. Seals and Gaskets

-

Replace all O-rings and gaskets with marine-rated replacements

-

Prevents saltwater ingress and coolant loss

4. Mounting Surface and Gear Alignment

-

Ensure the pump mounts flush to the engine front plate

-

Check gear backlash and spline shaft integrity

How Often Should You Replace the Raw Water Pump on a QSB 7.0?

Under normal marine operation, we recommend servicing the raw water pump every 300 to 500 engine hours, or at the beginning of every operating season—whichever comes first. However, you should replace the pump immediately if you experience:

-

Low sea water flow (visible at the exhaust outlet)

-

Overheating alarms

-

Leaking from the pump weep hole

-

Audible bearing noise or grinding

Common Causes of Raw Water Pump Failure

Understanding what leads to pump failure helps prevent unexpected downtime and costly repairs:

-

Dry Running: Starting the engine without water in the system damages the impeller quickly

-

Zinc Debris Contamination: Loose anode material can enter the impeller housing

-

Salt Build-Up: Crystallized deposits reduce flow efficiency

-

Improper Winterization: Freezing water inside the pump can crack housings and damage seals

To extend pump life, always flush the cooling system after use, especially in brackish or polluted waters.

Raw Water Pump Fitment Overview for Cummins QSB Series

While this catalog focuses on the QSB 7.0, this marine water pump also fits select QSB 5.9 and QSB 6.7 engines that use the same spline-drive, gear-mounted configuration. Confirm fitment by verifying:

-

Pump mounting bolt pattern

-

Gear tooth profile and shaft depth

-

Hose outlet/inlet size and angle

If you're unsure whether your current engine uses a keyed or splined impeller, our customer support team can help you verify by engine serial number or photos.

Trusted By Marine Professionals Around the World

With over 40,000 satisfied customers across 200+ countries, Diesel Pro Power is the go-to supplier for Cummins marine engine parts. Our marine-grade components for the QSB 7.0 platform are trusted in:

-

Offshore fishing fleets

-

Coast Guard patrol boats

-

Commercial transport barges

-

Island ferry systems

-

Tugboats and push boats operating in salt and brackish water

Looking Ahead: What to Add When Servicing the Pump

When replacing your Cummins QSB 7.0 raw water pump, consider the following accessories to ensure a complete and lasting installation:

-

Replacement Impeller: Even new pumps may require future impeller changes

-

Fresh Gasket Set: Prevent leaks at the pump housing or engine face

-

O-Ring Seal Kit: Ensure both inlet and outlet ports are leak-free

-

Zinc Anode Inspection: Check the condition of sacrificial zincs in the heat exchanger

-

Silicone Hoses & Clamps: Evaluate all hoses for soft spots, bulges, or cracking

If you need any of these items added to this catalog section, we can create a matching bundle with part listings.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588