Cummins QSM Parts - Cylinder Head Section

Loading...

Loading... Cylinder Heads & Related Components for Cummins QSM11

The Cummins QSM11 engine is a high-performance, 4-stroke, inline 6-cylinder diesel engine widely used in industrial and marine applications. Known for its fuel efficiency, power output, and durability, the QSM11 demands reliable top-end maintenance components to keep it performing at peak capacity.

Whether you're overhauling your engine after thousands of hours in service or repairing top-end damage, this section of our QSM11 parts catalog is dedicated to all major cylinder head components and supporting hardware. All products are compatible with Cummins QSM11 as well as select components shared with M11 and ISM engine platforms.

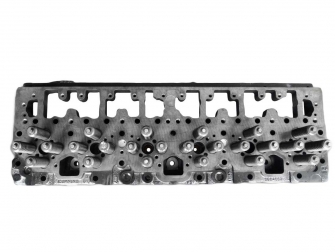

New QSM11 Cylinder Heads – With Valves and Springs Installed

We offer new cylinder heads for Cummins QSM11 engines that come fully loaded with factory-installed valves and springs. These ready-to-install assemblies save time and reduce rebuild risk by eliminating the need for separate valve installation and spring seating.

Key Features:

-

Pre-installed intake and exhaust valves

-

Factory-assembled valve springs, retainers, and seals

-

Machined for OE-level performance and sealing

-

Marine-ready option available for wet exhaust environments

These heads are suitable for marine propulsion engines, generator sets, and heavy industrial equipment. Choosing a complete head ensures optimal performance and fast turnaround during overhauls.

QSM11 Intake & Exhaust Valves

Intake valves for the QSM11 engine are designed for maximum airflow efficiency and high-temperature resistance. These valves allow fresh air to enter the combustion chamber, and their precision machining ensures a tight seal during the compression stroke.

Intake valves should be inspected or replaced if you observe:

-

Loss of compression

-

Valve seat recession

-

Poor cold starts or excessive black smoke

The QSM11 exhaust valves are exposed to some of the harshest operating conditions in the engine. These valves are designed to withstand extreme heat and pressure, especially in turbocharged configurations.

Common signs that exhaust valves may need replacement include:

-

White or bluish smoke at startup

-

Backfiring or incomplete combustion

-

Valve warping or erosion near the seat

Both valve types are direct replacements and are manufactured to Cummins specifications.

Valve Springs for Cummins QSM11

Valve springs maintain the proper seating force on intake and exhaust valves, ensuring they open and close at precisely the right moment. Worn springs can lead to valve float, misfires, or engine knock at higher RPMs.

Each QSM11 engine requires 24 valve springs—12 for intake and 12 for exhaust valves. It is best practice to replace springs when valves are being replaced or if the head is being rebuilt.

Cylinder Head Bolts for QSM11 Engines

Cylinder head bolts are torque-to-yield fasteners that should be replaced any time the cylinder head is removed. The QSM11 uses two types of bolts to secure the head:

-

Standard cylinder head bolts

-

Additional smaller bolts for specific support points

When installing a new cylinder head, using a full set of new bolts ensures proper clamping force across the head surface, preventing warping, head gasket failure, or coolant leaks.

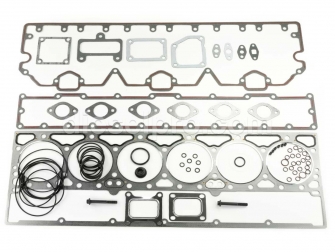

Upper Gasket Set for QSM11 Top-End Rebuild

A complete upper gasket set for the QSM11 is essential for resealing the engine during head installation. This set typically includes:

-

Head gasket

-

Rocker cover gasket

-

Valve stem seals

-

Thermostat housing gaskets

-

Injector O-rings

-

EGR gaskets (if equipped)

Always match your gasket set to the QSM11 platform to ensure compatibility with the cylinder head ports and coolant passages.

Valve Inserts and Guides

Valve seat inserts for intake and exhaust valves provide a hardened surface that resists wear, pitting, and thermal fatigue. During a full valve job or head rebuild, these inserts are replaced if the seating surface is worn, cracked, or recessed.

Using fresh inserts restores valve sealing efficiency and compression performance.

Valve guides maintain correct lateral movement of the valve stem. When valve guides become worn or misaligned, it can cause oil burning, uneven valve seating, or stem scoring. Our guides are manufactured to meet OE tolerance specs and should be installed in intake and exhaust positions in matching pairs.

Valve Stem Seals

Valve stem seals prevent oil from seeping into the combustion chamber via the valve stem. These seals are essential for oil control and valve train longevity, especially under turbocharged, high-pressure conditions common in QSM11 industrial and marine engines.

Replacing valve seals is recommended anytime the cylinder head is serviced or rebuilt.

Rocker Cover Components for QSM11

The rocker cover gasket prevents oil leaks from the valve cover. Our QSM11 rocker cover gaskets are available in updated material designs for enhanced longevity. These gaskets are precision-cut to fit the QSM11 rocker cover profile and resist degradation from heat and oil exposure.

Rocker Cover Housing Gasket

This gasket seals the rocker cover housing to the cylinder head. It's essential to replace this gasket during top-end work to maintain crankcase sealing and avoid oil leaks onto the exhaust manifold.

Temperature Switch for Engine Monitoring

Many Cummins QSM11 engines, particularly marine versions, utilize temperature switches to trigger alarms or engine shutdowns when coolant temperatures exceed safe levels. The replacement switch we offer is compatible with QSM11 platforms and closes the circuit at approximately 205°F. It fits ½” NPT threads and is widely used in marine and industrial control panels.

When Should You Replace the Cylinder Head on a QSM11 Engine?

Signs of cylinder head failure or wear may include:

-

Coolant entering the combustion chamber (white smoke from exhaust)

-

Frequent overheating

-

Poor compression in one or more cylinders

-

Pitting or cracks between valves

-

Excessive valve lash clearance

A new cylinder head is highly recommended if the original is warped, cracked, or has previously failed valve seats or guides. In marine environments, corrosion is also a major concern, making a new head with preinstalled components a safer long-term solution.

Planning a QSM11 Top-End Rebuild? Here’s What You’ll Need

A successful top-end rebuild on the QSM11 requires a complete combination of supporting components. Here is a checklist of everything you should consider:

|

Component |

Purpose |

|

New Cylinder Head |

Base of the rebuild; fully assembled for convenience |

|

Valve Set (Intake + Exhaust) |

Controls airflow in/out of the chamber |

|

Valve Springs |

Maintains valve timing and seating pressure |

|

Valve Guides |

Aligns the valve stem and reduces side wear |

|

Valve Stem Seals |

Prevents oil from leaking into combustion chamber |

|

Cylinder Head Bolts |

One-time use bolts that secure the head to the block |

|

Upper Gasket Set |

All required gaskets for top-end reassembly |

|

Rocker Cover Gasket & Housing Gasket |

Seals the valve cover area and prevents oil leaks |

|

Temperature Switch |

Helps monitor cooling system integrity in real-time |

Using new components throughout ensures long-term reliability, better compression, and reduced emissions. Replacing only select parts can cause premature failure or rework later.

QSM11 Engine Compatibility & Applications

The QSM11 is a variant of the Cummins 11-liter engine family and is found in:

-

Marine propulsion systems (including fishing vessels, workboats, and yachts)

-

Industrial generators

-

Off-highway equipment

-

Oilfield and gas compression applications

-

Locomotive and rail support systems

It shares certain components with the M11 and ISM engine platforms. However, it's important to use QSM11-specific cylinder head parts when it comes to gaskets, valves, and cylinder heads—especially for marine configurations.

Why Buy From Diesel Pro Power?

With more than 40,000 satisfied customers globally, Diesel Pro Power is trusted for high-quality diesel engine components shipped fast and backed by expert support.

Benefits of choosing Diesel Pro Power:

-

All parts are hand-inspected and stored in climate-controlled conditions

-

Worldwide shipping with same-day dispatch on in-stock items

-

Responsive customer service to help confirm part compatibility

-

Trusted by mechanics, fleet managers, marine operators, and industrial technicians

We stock what we list—and we know what fits. When you're rebuilding your Cummins QSM11 engine, you can rely on Diesel Pro to provide precision-matched parts for long-term uptime.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588