Cummins QSM Parts - Gasket Section

Loading...

Loading... Cummins QSM11 Gasket Kits & Sealants Catalog

The Cummins QSM11 is a robust, high-performance engine built to handle heavy-duty industrial, construction, and marine applications. Like any engine in its power class, routine maintenance and major overhauls eventually require a reliable gasket and seal replacement strategy. At Diesel Pro Power, we supply complete upper and lower gasket kits, individual seals, and high-performance sealants tailored for QSM11 engines to ensure proper resealing during overhauls, cylinder head work, or minor repairs.

With over 40,000 satisfied customers worldwide, Diesel Pro Power remains the trusted supplier for high-quality Cummins parts—including premium-grade QSM11 gasket sets and accessories that meet or exceed OEM specifications.

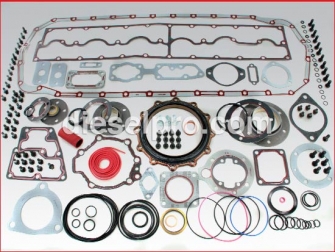

Complete Gasket Sets for Cummins QSM11

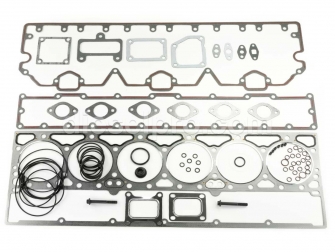

Cummins Upper Gasket Set for QSM11 Engines

Our upper gasket set for the Cummins QSM11 includes all the critical sealing components necessary for top-end rebuilds and repairs. This kit typically includes:

-

Cylinder head gasket

-

Rocker housing gaskets

-

Intake and exhaust manifold gaskets

-

Turbocharger oil supply and drain gaskets

-

Injector seals

-

Valve stem seals

-

Additional sealing hardware specific to the QSM11 engine configuration

The upper gasket set is critical during cylinder head overhauls or top-end refreshes. Whether you're performing a complete rebuild or simply addressing a leaking head gasket, this set provides a reliable seal to restore engine compression and prevent coolant or oil leaks.

Cummins Lower Gasket Set for QSM11 Engines

The lower gasket kit is essential when working on the crankcase, oil pan, or gear housing. This set includes:

-

Oil pan gasket

-

Front and rear crankshaft seals

-

Gear housing gaskets

-

Liner O-rings or seal rings

-

Water pump gasket (when applicable)

-

Accessory drive and mounting gaskets

Using a matched lower gasket set reduces the risk of future oil seepage and ensures all components are resealed with uniform material quality.

QSM11 Individual Gaskets & Seals

We also offer a full selection of standalone gaskets and seals for routine maintenance or partial rebuilds.

Rocker Cover and Rocker Housing Gaskets

-

Rocker Cover Gasket (Late Style): Provides a long-lasting seal between the rocker box cover and housing, helping prevent oil spray and crankcase vapor leaks.

-

Rocker Housing Gasket: Ensures the rocker box assembly seals effectively to the cylinder head.

These gaskets are critical for maintaining oil pressure and minimizing crankcase contamination in high-hour engines.

Oil Pan Gasket

-

Oil Pan Gasket (External Dampening): Designed specifically for QSM11 engines with external dampening systems. It creates a robust seal that withstands vibration and temperature cycling under heavy-duty use.

Exhaust Manifold Outlet Gasket

-

Seals the junction between the manifold outlet and turbo flange or pipe adapter. A new gasket here helps prevent exhaust leaks, improves turbo efficiency, and reduces under-hood heat buildup.

Front Cover and Gear Cover Seals

-

Front Cover Seal Ring: Prevents oil leakage at the timing gear access point.

-

Gear Cover Seal: Ensures the front gear train remains sealed against dirt, oil leaks, and pressure fluctuations.

Rectangular Ring Seals (Various Sizes)

These are critical for specialized passages, including oil and coolant routing. Using OEM-spec rectangular seals ensures reliable fitment and avoids compression-set failures under engine load.

Cylinder Liner Seal Rings

Cylinder liner sealing is a vital concern for long-life engines like the QSM11. Our liner seal rings (O-rings) are manufactured for maximum elasticity and chemical resistance. They help prevent coolant and combustion gas migration into unintended areas, protecting the engine block and liner integrity.

-

These rings are also used across compatible engines such as L10, M11, and ISM, but our inventory is QSM11-ready.

Turbocharger Gaskets

-

Turbo Oil Supply Gasket: Ensures the oil feed line to the turbocharger is properly sealed. A compromised seal here can result in pressurized oil leaks, risking turbo bearing failure.

-

Turbo Mounting Gasket: Maintains a tight connection between the turbo base and exhaust manifold, preventing exhaust bypass and heat damage to nearby components.

Oil Cooler Gaskets

QSM11 engines use a high-efficiency oil cooler system to maintain optimal operating temperatures.

-

Our oil cooler gaskets are designed for high thermal loads and long-term durability. Replacing these during an oil cooler service or removal ensures proper resealing.

Hand Hole Gaskets

The QSM11 engine includes several hand-hole inspection ports for maintenance. Our hand hole gaskets ensure these access points are sealed correctly, preventing oil seepage during engine operation.

Sealants and Specialty Compounds for Gasket Replacement

Silkolene High-Temperature Jointing Compound

-

This jointing compound is ideal for turbo mounting surfaces or exhaust manifold gaskets.

-

Designed to withstand extreme heat, ranging from 550°C to 760°C.

-

Recommended for both Detroit Diesel and Cummins turbo applications.

High Tack Gasket Spray

-

Designed to hold gaskets in place during installation and improve initial seal formation.

-

Ideal for vertical or difficult-to-access surfaces where gasket slippage is a concern.

3H Liquid Gasket Maker

-

A versatile, brush-on liquid sealant that fills surface imperfections and complements conventional gasket installations.

-

Especially useful for uneven or older sealing surfaces.

Red Threadlocker (High Strength)

-

Used for bolting components where vibration may loosen fasteners (e.g., exhaust studs, gear cover bolts).

-

Withstands high heat and mechanical stress without loosening.

RTV Silicone Gasket Makers

We stock a full range of RTV sealants, each optimized for specific temperature and sensor compatibility requirements:

-

Sensor-Safe RTV (Blue and Ultra Blue): Safe for use around oxygen sensors and electronic engine management systems.

-

High Temp RTV (Red): Designed for sealing turbocharger and exhaust components where high heat resistance is needed.

-

Non-Hardening Pliable Sealant: Ideal for components that may require future disassembly, such as access plates or inspection covers.

J-B Weld Cold Weld

-

Epoxy-based solution for emergency repairs or non-pressurized crack sealing.

-

Compatible with both cast iron and aluminum Cummins components.

Why Proper Gasket Selection Matters

Choosing the correct gasket set or sealant isn’t just about fit—it’s about reliability. In QSM11 engines operating in demanding marine or industrial environments, improper sealing can lead to:

-

Oil leaks that reduce pressure and damage internal components

-

Coolant seepage that promotes cavitation or liner pitting

-

Exhaust leaks that reduce turbocharger efficiency

-

Increased wear on mating surfaces

-

Costly unscheduled downtime

All of our gaskets and sealants are designed to withstand the specific thermal, chemical, and vibrational stresses associated with QSM11 diesel operation.

When to Replace Gaskets in a Cummins QSM11 Engine

During Overhaul: Always replace all gaskets and seals with new ones during any engine rebuild to ensure compression and fluid containment.

During Component Replacement: When changing the cylinder head, water pump, turbocharger, oil cooler, or timing gears, always use new gaskets to prevent leaks.

When Seepage is Detected: If oil or coolant seepage is visible at mating surfaces, reseal that component immediately. Seemingly minor leaks can become major issues under load.

If Using Non-OEM Gasket Sets Previously: Low-cost aftermarket gaskets often degrade faster or don’t seal correctly. Diesel Pro Power offers OEM-grade options that last.

Why Diesel Pro Power?

-

40,000+ Customers Worldwide trust us for diesel engine parts.

-

Fast Shipping from our U.S. warehouse means minimal downtime.

-

Spanish-Speaking Support (Hablamos Español).

-

Marine and Industrial Focus: We understand the unique sealing challenges in offshore, port, construction, and industrial applications.

-

Dedicated Support: Need help identifying your QSM11 configuration or CPL? Our team can assist.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588