The Detroit Diesel 471 Non-Turbo 4-Valve engine is a variant of the legendary 71 Series lineup. Built for reliability, durability, and field serviceability, this model features a naturally aspirated design paired with a 4-valve cylinder head, offering improved airflow and efficiency. This engine is a mechanical marvel appreciated by operators in marine, generator, and industrial settings. With no turbocharging, fewer electronics, and a proven two-stroke platform, the 471 4-valve engine is favored in long-service marine vessels, military support equipment, classic diesel trucks, and backup power units. Its 4-valve head delivers better breathing—leading to more complete combustion and slightly improved fuel economy and performance—without compromising on the simplicity that the 471 series is known for. At Diesel Pro Power, we proudly support this engine with premium aftermarket parts that outperform or match OEM standards. With quick shipping, expert support, and a full line of service kits, rebuild parts, and replacements, we’re here to ensure your 471 4-valve engine keeps running strong. Model: Detroit Diesel 471 (4-cylinder) Series: 71 Series two-stroke engine Valvetrain: 4 valves per cylinder Number of Cylinders: 4 (inline configuration) Aspiration: Naturally aspirated (non-turbo) Fuel System: Mechanical unit injectors (timed and pressure-actuated) Cycle: Two-stroke diesel Firing Order: 1-3-4-2 Compression Ratio: ~17.0:1 Rated Power Output: Approx. 130–160 HP @ 1,800–2,100 RPM (depending on governor settings and injector size) GovernDimensions or Options: Mechanical (limiting and variable speed) Bore: 4.25 inches (108 mm) Stroke: 5.00 inches (127 mm) Displacement: 284 cubic inches (4.65 liters) Oil Capacity (with filter): ~7.5 gallons (28.4 liters) Cooling System Capacity: ~6.5 gallons (24.6 liters) Oil Pressure (at operating RPM): 40 – 60 PSI Operating Temperature Range: 170°F – 195°F Maximum Allowable Coolant Temp: 200°F Idle RPM Range: 500 – 600 RPM Rated RPM Range: 1,800 – 2,100 RPM Dry Weight (Base Engine): ~1,650 lbs (748 kg) Length: ~52 inches (132 cm) Width: ~29 inches (74 cm) Height: ~39 inches (99 cm) The main difference lies in the cylinder head configuration: 2-Valve Head: One intake and one exhaust valve per cylinder. Standard breathing capacity. 4-Valve Head: Two intake and two exhaust valves per cylinder. Enhanced air intake and exhaust flow. Improved Airflow: Increased volumetric efficiency for better combustion and marginally higher horsepower. Lower Emissions: Cleaner exhaust due to more complete fuel burn. Better Performance at Higher RPMs: Especially useful in marine vessels or equipment under constant load. Greater Efficiency: Slight improvement in fuel economy and throttle response. This engine variant has powered countless vessels across oceans, harbors, and rivers for decades. It's especially valued in environments where dependability and mechanical simplicity are more important than digital controls or high-horsepower performance. Vintage Yachts & Trawlers: A favorite among restorers of 1960s–1980s long-range trawlers and live-aboard boats. Personal Fishing Vessels: Valued for simplicity and cold-start reliability in seasonal sportfishing boats. Retrofit Marine Projects: Often used in sailboats or smaller cruisers as a backup or main propulsion engine. Shrimp Boats & Crabbers: Especially in the Gulf of Mexico and Alaska. Work Barges & Dredges: Trusted in high-torque, low-speed workboats. Ferry Vessels: Deployed in older passenger ferries where engine rooms have tight space constraints. Tugboats: Used in harbor tugboats or assist vessels in regional ports. Outside marine service, this engine has seen widespread industrial deployment: Generators: Common in standby and primary power units from 40–80 kW. Hydraulic Pumps & Water Movers: Used in irrigation, flood control, and mining operations. Construction Equipment: Formerly installed in cranes, rock crushers, and earthmoving machines. Drilling Rigs: Found in well-servicing units and oilfield equipment. Portable Compressors & Air Units: Especially in military or government setups. The U.S. Armed Forces and several NATO militaries have relied on the 471 family for decades: Landing Craft & Amphibious Assault Boats Transportable Generator Sets Tank Recovery Vehicles Fuel Transfer Systems Its 4-valve head variant is preferred in high-output environments where constant load and air efficiency are vital. At Diesel Pro Power, we recognize that most 471 engines still in service today are decades old. OEM parts are no longer produced in volume, and many suppliers no longer carry complete kits for the 4-valve variant. That's where we step in. We provide a full range of aftermarket parts for this engine that meet or exceed OEM tolerances, including: Marine Detroit Diesel 4-71 Component Maintenance Life Practical Guide To Servicing Your Detroit Diesel 71 Series Inline (271, 371, 471, & 671 ) – Part 1 Engine Components and Their Roles (Covering Detroit Diesel 271, 371, 471, 671 Engines) Key Maintenance Procedures (Covering Detroit Diesel 271, 371, 471, 671 Engines) Assembly and Disassembly Guidelines (Covering Detroit Diesel 271, 371, 471, 671 Engines) Safety Protocols for Technicians (Working On Detroit Diesel 271, 371, 471, 671 Engines) Torque Specifications And Wear Limits (Covering Detroit Diesel 271, 371, 471, 671 Engines) Disassembly Of Throttle Controls For Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671) DISASSEMBLY OF AIR BOX COVERS FOR DETROIT DIESEL 71 SERIES INLINE ENGINES (271, 371, 471, 671) Disassembly Of The Blower For Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671) Removing Air Box Drains For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) REMOVING THE VALVE ROCKER COVER ON A DETROIT DIESEL 71 SERIES INLINE ENGINE (271, 371, 471, 671) Torque Specifications Of 71 Series Inline Engines (271, 371, 471, 671) Disassembly Of Components For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Key Components of the Oil Pump and Model-Specific Variations (271, 371, 471, 671) INSIGHTS FROM THE DETROIT DIESEL 71 SERIES INLINE ENGINE MANUAL VOLUME 2 (271, 371, 471, 671) LUBRICATION SYSTEM FOR DETROIT DIESEL 71 SERIES INLINE ENGINES (271, 371, 471, 671) Disassembly of the Oil Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Reassembly of the Oil Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Oil Filters For Detroit Diesel 71 Series Inline Engines (271,371, 471, 671) LUBRICATING OIL PRESSURE REGULATOR FOR DETROIT DIESEL 71 SERIES INLINE ENGINES (271, 371, 471, 671) Oil Cooler For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Oil Pan For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Ventilating System for Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Oil Pump Maintenance For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Radiator Cooling For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Cooling System and Heat Exchanger For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Cooling System Configurations For 71 Series Inline Engines (271, 371, 471, 671) Types of Coolant for Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Chemicals & Coolant For Your Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671) Maintaining The Heat Exchanger Core For Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671) Guidelines for Coolant For Detroit 71 Series Inline Engines (271, 371, 471, 671) Introduction to the Water Pump System for the 71 Series Inline Engine (271, 371, 471, 671) Disassembly of the Freshwater Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Reassembly of the Freshwater Pump For Detroit Diesel 71 Series Inline (271, 371, 471, 671) Freshwater Pump Maintenance For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Raw Water Pump Maintenance (Marine Application) For 71 Series Inline Engines (271, 371, 471, 671) Disassembly of the Raw Water Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Reassembly of the Raw Water Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Water Pump For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Thermostat Operation For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) SYSTEMATIC APPROACH TO TROUBLESHOOTING DETROIT DIESEL 71 SERIES INLINE ENGINES (271, 371, 471, 671) Cooling System Troubleshooting For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Troubleshooting Tips for Improved Efficiency In Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671) Detroit Diesel 271,371,471,671 Inline Engine Tune Up Guide Disassembly Turbocharger (If Equipped) For Detroit Diesel 71 Series Inline Engines (471, 671) Disassembly Of Turbochargers For Detroit Diesel 71 Series Inline Engines – (471, 671)

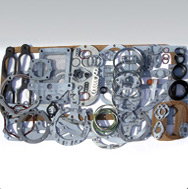

Parts for Detroit Diesel 471 Non-Turbo - (4 Valve Head Type)

-

Select Parts Category

Loading...

Loading... Detroit Diesel 471 Non-Turbo 4-Valve Engine Specifications & Applications

Overview of the Detroit Diesel 471 Non-Turbo 4-Valve Engine

Key Specifications of the Detroit Diesel 471 4-Valve Non-Turbo Engine

Engine Configuration

Internal & Capacities

Engine Weight and Dimensions

What’s the Difference Between 2-Valve and 4-Valve 471 Engines?

Benefits of 4-Valve Configuration

Marine Applications of the Detroit Diesel 471 4-Valve Engine

Recreational Marine Use

Commercial Marine Use

Industrial Applications of the 471 Non-Turbo 4-Valve Engine

Military Applications of the 471 4-Valve

Aftermarket Support for the 471 4-Valve Engine

Additional Resources

AIR SCAVENGING AND BLOWER SYSTEM FOR DETROIT DIESEL 71 SERIES INLINE ENGINES (271, 371, 471, 671)

Best Practices for Keeping Air Intake and Exhaust Systems Clean For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Cleaning and Inspection Processes For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Safe Cleaning Procedures Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671)

Critical Inspection Points For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Valve and Injector Maintenance For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Checking Valve Clearance and Injector Timing For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Tools and Equipment For Maintaining Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Detailed Overhaul Process For Detroit Diesel 71 Series Inline Engine (271, 371, 471, 671)

Common Troubleshooting Tips For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Disassembly Of Fuel Lines For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Disassembly Of Exhaust Manifold For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Disassembling The Air Cleaner & The Air Shutdown Housing For Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

Summary of Troubleshooting and Specifications In Detroit Diesel 71 Series Inline Engines (271, 371, 471, 671)

FAQ From Detroit Diesel 71 Series Inline Engine Service Manual (271, 371, 471, 671)

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588