The Detroit Diesel 8V71 Non-Turbo engine is a naturally aspirated, V8 two-stroke diesel engine from the iconic Series 71 family. With its proven mechanical simplicity, solid low-end torque, and long-lasting reliability, the 8V71 non-turbo engine has been the backbone of commercial marine fleets, industrial machines, military equipment, and power generators for decades. Equipped with eight cylinders in a 90-degree V configuration, this engine delivers more horsepower and torque than its smaller siblings (6V71, 6-71, or 4-71) while maintaining the modular, serviceable architecture that made Detroit Diesel engines globally respected. The non-turbo setup makes it easier to maintain, eliminates turbo-related failure points, and provides smooth, dependable power delivery. At Diesel Pro Power, we support the 8V71 Non-Turbo engine with a full line of aftermarket parts—including overhaul kits, cylinder heads, gaskets, injectors, and cooling components. Our high-quality replacements are built to match or exceed OEM specifications, and we offer fast worldwide shipping to keep your engine—and your operation—running strong. Engine Series: Detroit Diesel Series 71 Model: 8V71 Non-Turbo Engine Type: 2-Stroke Diesel Configuration: V8 (90-degree angle) Aspiration: Naturally Aspirated (no turbocharger) Valvetrain: 4 valves per cylinder Firing Order: 1-2-7-8-4-5-6-3 Fuel System: Mechanical unit injectors (pressure-timed) Governor Type: Mechanical (variable or limiting speed) Compression Ratio: ~17:1 Bore: 4.25 inches (108 mm) Stroke: 5.00 inches (127 mm) Displacement (Total): 568 cubic inches (9.3 liters) The 8V71 Non-Turbo engine uses the same bore and stroke as other Series 71 models, but with eight cylinders it offers more output for heavy-duty applications where performance and load-carrying are critical. Power output for the 8V71 Non-Turbo varies based on injector size and RPM settings. Common injector sizes include: Injector Size Approx. Horsepower @ RPM N55 ~260 HP @ 1,800 RPM N60 ~275 HP @ 2,100 RPM N65 ~290 HP @ 2,100 RPM N70 ~305 HP @ 2,100 RPM Rated RPM Range: 1,800 – 2,100 RPM Idle RPM: 500 – 600 RPM Oil Capacity (with filters): ~14 gallons (53 liters) Coolant Capacity: ~8.5 gallons (32 liters) Operating Oil Pressure: 40 – 60 PSI at rated RPM Thermostat Operating Range: 170°F – 195°F Maximum Coolant Temp: 200°F The large oil and cooling capacities reflect the engine’s V8 structure and the added need for thermal management during long duty cycles. Length: ~63 inches (160 cm) Width: ~42 inches (107 cm) Height: ~50 inches (127 cm) Dry Weight: ~2,600 – 2,800 lbs (1,180–1,270 kg), depending on accessories Despite its eight-cylinder configuration, the 8V71 is compact enough for most large marine engine rooms, machinery bays, and mobile industrial applications. No turbocharger, no electronics—just classic Detroit Diesel engineering that’s easy to repair with common tools and mechanical know-how. Each cylinder head covers two cylinders and can be serviced or replaced independently, saving time and reducing maintenance costs. Many 8V71s remain in service after 30,000+ operating hours thanks to robust engineering and ready availability of quality aftermarket rebuild parts. With proper block heaters or ether assist, the 8V71 non-turbo version starts reliably in cold conditions, making it ideal for commercial fleets operating in variable climates. The 8V71 Non-Turbo engine has been widely deployed in both commercial and recreational vessels, offering a balance of power, reliability, and easy serviceability. Tugboats and Push Boats: Used for harbor assist, river towing, and barge transport Crabbers and Shrimpers: Found in fishing fleets from Alaska to the Gulf Coast Passenger Ferries and Crew Boats: Provides reliable, consistent operation in commuter or charter service Utility and Workboats: Runs deck winches, cranes, pumps, and auxiliary systems Landing Craft and Barges: Offers steady propulsion in shallow and variable-draft vessels Classic Trawlers and Liveaboard Boats: Found in older Hatteras, Grand Banks, and other luxury yachts from the 1960s–1980s Boat Restorations: Valued by owners restoring vintage commercial boats for private or charter use Twin Engine Configurations: Popular in large vessels with dual 8V71s for redundancy and torque The 8V71 Non-Turbo is equally at home in land-based equipment requiring long hours of consistent output. Standby and Prime Power Generators (100–150 kW): Used in mining camps, hospitals, and government installations Irrigation and Water Transfer Systems: Drives high-capacity pumps in agriculture and flood management Air Compressors: Operates pneumatic drilling and pressure systems in oilfields Heavy Construction Equipment: Installed in trenchers, dozers, and cranes Drilling Rigs and Skid Units: Provides mechanical or hydraulic drive power The U.S. military and allied forces used the 8V71 extensively for: Landing Craft (LCM-8s, LCU) Amphibious Assault Boats Field Power Generators Armored Vehicles and Transport Trucks Civil Defense Systems (Cold War-era infrastructure) These engines are still found in government reserve fleets, NGO disaster relief teams, and repowered international military units. Well-maintained 8V71 engines can last for decades, but common signs that a rebuild or major service is due include: Excessive Exhaust Smoke (Blue or Black): Indicates worn rings, injectors, or poor combustion Oil in Coolant or Vice Versa: Sign of gasket failure or liner seal leaks Blow-by: Increased crankcase pressure suggests piston ring or liner wear Hard Starting or Loss of Power: Injector, compression, or timing issues Oil Consumption Increases: Could be valve guide or cylinder wear Diesel Pro Power offers complete in-frame and out-of-frame overhaul kits, matched to your injector size and application. The Legacy of the Detroit Diesel Marine 8V71 Engine & Its Use Today Aftermarket Parts For A Detroit Diesel 8V71 Engine Overview of the Detroit Diesel V71 Series Engines (6V71, 8V71, 12V71, 16V71) General Service Guidelines for Detroit Diesel V71 Series Engines (6V71, 8V71, 12V71, 16V71) Cylinder Block for Detroit Diesel V71 Series Engines (6V71, 8V71, 12V71, 16V71) Cylinder Head for Detroit Diesel V71 Series Engines (6V71, 8V71, 12V71, 16V71) Common Maintenance and Repair Needs for Detroit Diesel V71 Cylinder Heads (6V71, 8V71, 12V71, 16V71) Fuel and Air Systems for Detroit Diesel 6V71, 8V71, 12V71, and 16V71 Engines Injectors Maintenance for Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Governor Maintenance for Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Blowers Maintenance for Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Air Filters Maintenance for Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Fuel Leaks Troubleshooting for Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Air Intake Restrictions for Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Injector Malfunction Troubleshooting for Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Lubrication and Cooling Systems for Detroit Diesel 6V71, 8V71, 12V71, and 16V71 Engines Electrical and Exhaust Systems for Detroit Diesel 6V71, 8V71, 12V71, and 16V71 Engines Troubleshooting and Preventive Maintenance for Detroit Diesel 6V71, 8V71, 12V71, and 16V71 Engines Specifications and Torque Tables for Detroit Diesel 6V71, 8V71, 12V71, and 16V71 Engines Safety Considerations for Detroit Diesel 6V71, 8V71, 12V71, and 16V71 Engines Lubrication System: Comprehensive Guide For Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Oil Pumps for Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Oil Pressure Regulation For Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Oil Filters for Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Cooling System: Comprehensive Guide For Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Types of Cooling Systems for Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Key Components of the Cooling System for Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Raw Water Pump Specifics for Detroit Diesel V71 Marine Engines (6V71, 8V71, 12V71, 16V71) Importance of Cooling System Maintenance for Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Detailed Torque and Specifications For Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Step-by-Step Maintenance Procedures For Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Oil Pump Removal and Reassembly for Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Draining and Refilling the Cooling System For Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Troubleshooting Guide For Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Complete Parts Catalog for Detroit Diesel V71 Engines (6V71, 8V71, 12V71, 16V71) Comprehensive FAQ for Detroit Diesel V-71 Series Manual (6V71, 8V71, 12V71, 16V71)

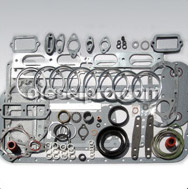

Parts for Detroit Diesel 8V71 Non-Turbo

-

Select Parts Category

Loading...

Loading... Detroit Diesel 8V71 Non-Turbo Engine Specifications & Applications

Introduction to the Detroit Diesel 8V71 Non-Turbo Engine

Core Engine Specifications

Bore, Stroke, and Displacement

Power Ratings by Injector Size

Torque Output: ~720–850 lb-ft depending on configuration

Oil and Cooling System Capacities

Engine Dimensions and Weight

Key Benefits of the 8V71 Non-Turbo Design

Pure Mechanical Simplicity

Modular Components

Long-Lasting Power

Cold Start Reliability

Marine Applications of the Detroit Diesel 8V71 Non-Turbo

Commercial Marine Use

Recreational and Restoration Use

Industrial and Generator Applications

Military and Emergency Use

Common Rebuild Intervals and Service Signs

Additional Resources

Marine Detroit Diesel 8V71 Component Maintenance Life

Detroit Diesel 6V71, 8V71, 12V71, 16V71 Engine Tune Up

Introduction to the Practical Guide to Servicing Your Detroit Diesel V71 Series Engines (6V71, 8V71, 12V71, 16V71)

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588