The Twin Disc MG521 marine transmission is renowned for its robust construction, smooth power transfer, and long-lasting reliability. It’s designed to meet the demands of a wide range of marine applications, including fishing boats, tugboats, workboats, and offshore supply vessels. At Diesel Pro Power, we provide a comprehensive selection of MG521 parts, including rebuilt transmissions, overhaul plate kits, gasket sets, plate kits, rubber blocks, and oil pump and filter assemblies. Our commitment to exceptional quality, fast shipping, and expert support ensures your MG521 transmission remains operational with minimal downtime. Our rebuilt Twin Disc MG521 marine transmissions are meticulously reconditioned to meet and exceed OEM specifications, ensuring smooth, reliable operation and long-lasting durability. Each rebuilt unit undergoes complete disassembly, thorough inspection, precision reassembly using high-quality components, and rigorous testing to ensure optimal performance under real-world conditions. Every rebuilt MG521 transmission comes equipped with essential components, including: Mechanical selector valve assembly (control valve) – For precise, responsive gear shifting and reliable power transfer. Pilot housing flange – Ensures secure, stable mounting between the transmission and engine. Oil pump – Maintains continuous oil flow, providing critical lubrication to reduce friction and extend component life. Oil level gauge – Facilitates easy monitoring of fluid levels, promoting regular maintenance. Output flange – Provides a secure connection to the propeller shaft, ensuring efficient and reliable power transfer. Note: Drive ring is sold separately. All rebuilt MG521 transmissions are sold with a refundable core deposit. See details for more information. The 2.0:1 ratio strikes an excellent balance between speed and torque, making it a versatile choice for commercial fishing boats, mid-sized workboats, and recreational vessels. It offers efficient cruising performance while maintaining adequate thrust for typical operational conditions. Vessels that require smooth maneuverability combined with fuel efficiency benefit greatly from this ratio. It’s ideal for operations where moderate load and quick responsiveness are essential. The 3.0:1 ratio provides enhanced pulling power, delivering superior torque for vessels that handle heavier loads, such as utility vessels, offshore supply boats, and larger fishing vessels. This ratio is ideal for applications where strong propulsion is needed for towing, hauling, or operating in challenging conditions with variable loads. The 3.0:1 ratio ensures a balance between dependable thrust and manageable speed for operators needing both power and versatility. The 3.5:1 ratio offers even greater torque, making it suitable for larger workboats, trawlers, and vessels engaged in demanding operational conditions. This ratio excels in scenarios where enhanced control and strong power delivery are essential, such as rough seas, heavy payloads, or continuous operations. Vessels equipped with the 3.5:1 ratio benefit from improved handling and stability while maintaining reliable fuel economy and power output. The 4.0:1 ratio delivers maximum torque and exceptional control, making it the go-to choice for tugboats, large cargo vessels, offshore support craft, and other heavy-duty marine operations. This ratio excels in situations where powerful, steady propulsion is required for maneuvering in ports, towing large loads, or maintaining position in strong currents. Its high torque output ensures smooth and confident operation under even the most demanding marine conditions, providing peace of mind and superior performance for vessel operators. Our overhaul plate kit includes all the brass friction plates and steel plates needed for a complete clutch rebuild, restoring smooth engagement and consistent transmission performance. Designed to withstand high loads and continuous use, this kit ensures long-term operational efficiency. A complete gasket set featuring main housing gaskets, O-rings, seal rings, and auxiliary gaskets. These components ensure a leak-free seal, maintaining system pressure and integrity during maintenance or overhaul. Manufactured from premium materials for durability in harsh marine environments. A selection of individual brass and steel plates for targeted clutch repairs. Ideal for addressing specific wear or damage, this kit offers a cost-effective solution for maintaining smooth clutch performance. The rubber block, also known as a torsional isolator, connects the transmission output flange to the propeller shaft. It effectively absorbs vibrations, reduces stress on drivetrain components, and compensates for misalignments caused by hull flex or engine movement. Made from durable, marine-grade materials for long-lasting performance. The oil pump and filter assembly ensures consistent lubrication and filtration of transmission fluid, reducing wear on internal components and extending transmission life. The oil pump maintains continuous oil flow under demanding conditions, while the filter removes contaminants for optimal system performance. 24-Hour Worldwide Shipping: Orders are processed and shipped quickly to minimize vessel downtime. Extensive Inventory: We carry a comprehensive selection of MG521 parts in stock and ready to ship. Expert Customer Support: Our team provides guidance on product selection, installation, and maintenance. Over 15,000 Satisfied Customers: Trusted by marine operators and mechanics worldwide for quality parts and reliable service. Easy Online Shopping: Our user-friendly website makes it simple to browse, select, and order parts from the comfort of your home or office. The MG521 is used in a variety of vessels, including fishing boats, tugboats, offshore supply vessels, workboats, and recreational vessels. Essential parts include the rebuilt gear, overhaul plate kit, gasket set, plate kit, rubber blocks, and oil pump and filter. A complete set of brass friction plates and steel plates, designed to restore smooth clutch engagement and reliable performance. We offer 24-hour worldwide shipping, ensuring fast delivery to your location. Yes! Our parts are engineered to meet or exceed OEM standards, providing dependable performance and longevity. Our website makes it easy to find parts specific to your engine. For additional guidance, our expert support team is available to assist. Look for fluid leaks, slipping gears, overheating, unusual noises, or reduced performance. Absolutely! Our knowledgeable team is available to provide expert advice, troubleshooting support, and installation guidance. Yes! We offer a wide selection of parts for other Twin Disc models, all available through our online store. Visit our website, browse the MG521 parts catalog, select your items, and complete your order online. Contact us if you have any questions. Choose Diesel Pro Power as your trusted supplier of Twin Disc MG521 marine transmission parts. With fast shipping, expert support, and quality you can rely on, we make it easy to keep your MG521 running smoothly. Explore our catalog today and place your order with confidence. For assistance, contact us at 888-433-4735 (US) or 305-545-5588 (International) during business hours (8 a.m. to 5 p.m. EST, Monday–Friday). The Twin Disc MG521 is a high-capacity marine transmission built for continuous-duty performance in offshore, commercial fishing, towing, and industrial marine operations. Designed for reliability and torque stability under demanding workloads, the MG521 is an evolution of Twin Disc’s trusted geartrain architecture—offering enhanced reduction ratios, heavy-duty internal components, and dependable hydraulic clutch engagement. Its compatibility with high-horsepower diesel engines and optional power take-off (PTO) systems makes it a preferred solution for operators running workboats, trawlers, dredgers, and supply vessels. The MG521 can be configured for straight or down-angle installations, providing installation flexibility for a range of hull types and engine room layouts. Type: Heavy-duty marine transmission with oil-cooled hydraulic clutch Horsepower Rating (Approximate): Continuous Duty: Up to 1,000 HP @ 1800 RPM Intermittent Duty: Up to 1,200 HP @ 2300 RPM Maximum Input Speed: 2500 RPM Reduction Ratios Available: 2.00:1 2.50:1 3.00:1 3.50:1 4.00:1 4.50:1 Input Housing: SAE No. 0 or SAE No. 1 Flywheel Compatibility: 18", 14" Clutch Type: Hydraulically actuated multi-disc, oil-cooled Cooling System: Oil-to-water heat exchanger standard Lubrication System: Pressure lubrication with internal oil pump Oil Capacity: Approximately 24–30 quarts Dry Weight: Approximately 1,600–1,900 lbs depending on ratio and configuration Mounting Options: Straight or 8° down-angle output Rotation Compatibility: Bi-directional input for LH or RH engines Optional Features: Hydraulic or mechanical PTO Trolling valve Flexible or rigid engine mounts Electronic shift controls The MG521 is engineered for rugged, continuous-duty operation and is frequently found in: Tugboats and Pushboats: Where high bollard pull and torque are needed for prolonged propulsion tasks Commercial Fishing Vessels: Ideal for deep-sea trawlers, seiners, and longliners operating long hours offshore Offshore Support Vessels (OSVs): Delivers stable, high-load propulsion for vessels servicing oil rigs and platforms Dredging and Mining Support Craft: With strong PTO compatibility for hydraulic pumps and support equipment Harbor Utility and Workboats: Provides durable performance in towing, line handling, and cargo transport roles Designed to support engines producing 800 to 1,200 horsepower, the MG521 is compatible with a range of commercial diesel engines used in marine propulsion: Cummins KTA38-M Cummins QSK38 (commercial duty ratings) Caterpillar 3412E Caterpillar C32 (mid-range ratings) MTU Series 2000 and 4000 (lower ratings) Detroit Diesel 16V92 Detroit Diesel 16V149 High Torque Capacity: Built for marine applications requiring constant power delivery under heavy load Wide Ratio Selection: Allows for tailored propulsion performance across vessel types Efficient Clutch Engagement: Hydraulic clutch system ensures minimal wear and smoother transitions Durable Internal Architecture: Forged gears and precision-machined shafts for long service life Flexible Configuration: Available in both straight and down-angle outputs to suit new and existing installations Vessel Type MG521 Suitability Notes Tugboats (Harbor & River) Excellent Delivers required torque for heavy push/pull ops Offshore Supply Vessels Excellent High-load geartrain matches OSV mission profiles Deep-Sea Fishing Vessels Excellent Withstands hours of propulsion with variable load Dredging and Support Craft Excellent Strong PTO pairing for auxiliary hydraulic systems Passenger Ferries and Yachts Not Ideal Overpowered for light-duty, high-speed recreational use Overview of the MG521 marine transmission Intended applications in marine environments Safety disclaimer and reference to OEM manuals for deeper technical data Understanding Twin Disc’s no-guarantee policy from official documentation Basic design characteristics Performance parameters (torque, gear ratios, max input RPM) Lubrication type and oil capacity Operating temperature range Mounting orientation and space considerations Pre-installation inspection Alignment with engine and shaft Foundation and mounting bolt torque Flange connections Coupling procedures and tolerances Hydraulic and mechanical control hookup procedures Safety and PPE requirements during installation Checklist before first start Priming the oil system First run parameters and idle check Oil pressure verification Troubleshooting during startup Noise and vibration analysis Maintenance intervals (daily, 250 hours, annually) Lubrication change frequency Filter inspection and replacement Linkage and control cable checks Alignment verification Fastener and bolt re-torque inspection Best practices for operating hours logging Signs of wear or damage (noise, heat, metal shavings) Disassembly procedure Gear tooth inspection – pitting, wear, scoring Bearing play, end float measurement Cleaning procedures for removed components Installation of new gears and bearings Rechecking gear backlash and alignment Reassembly and torque specs Post-repair testing and diagnostics Slipping or delayed engagement Unusual noises (whine, grind, knock) High operating temperatures Oil leaks (input/output seal, sump) Low oil pressure Excessive vibration Troubleshooting charts and flow processes Emergency bypass procedures Mechanical control linkage vs. EC300 electronic controls Cable routing and securement Calibrating control responses Synchronization with throttle systems Troubleshooting control signal loss Control system bleed procedures (if applicable) Disconnecting from engine and shaft Draining oil and safe containment Lifting techniques and rigging requirements Inspection before reinstallation Re-torquing mounting and coupling hardware Oil refill and priming procedure Operational checks after reinstallation Common wear components (clutch plates, seals, bearings) Recommended replacement intervals Interchangeable parts and aftermarket options Diesel Pro Power premium rebuild kits Importance of using proper gasket and seal kits Torque specs for major component reinstallation Overview of rebuild kits available Comparison to OEM parts Diesel Pro Power aftermarket kits with OEM matching warranty Contents of standard rebuild kits Plate kits, gasket kits, seal kits, and bearings When to replace full assemblies vs. individual parts Lead times, support, and ordering from Diesel Pro

Twin Disc MG 521 Marine Transmission Parts

-

Select Parts Category

Loading...

Loading... Twin Disc MG521 Marine Transmission Reb uilt Transmissions & Parts Catalog

Introduction: Premium-Quality Parts for Smooth, Reliable Marine Performance

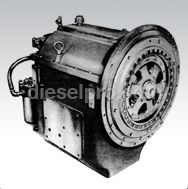

Rebuilt Twin Disc MG521 Marine Transmissions for Sale

Twin Disc MG521 Marine Transmission 2.0:1 for Sale

Twin Disc MG521 Marine Transmission 3.0:1 for Sale

Twin Disc MG521 Marine Transmission 3.5:1 for Sale

Twin Disc MG521 Marine Transmission 4.0:1 for Sale

Our Selection of Twin Disc MG521 Parts

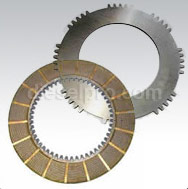

Overhaul Plate Kit – For Twin Disc MG521 Transmission

Gasket Set – For Twin Disc MG521 Transmission

Plate Kit – For Twin Disc MG521 Transmission

Rubber Blocks (Couplings) – For Twin Disc MG521 Transmission

Oil Pump and Filter – For Twin Disc MG521 Transmission

Why Choose Diesel Pro Power for MG521 Parts?

Frequently Asked Questions (FAQs) about the Twin Disc MG521

1. What types of vessels use the MG521 transmission?

2. What essential parts should I have on hand for MG521 maintenance?

3. What’s included in the overhaul plate kit?

4. How fast can I get MG521 parts from Diesel Pro Power?

5. Are Diesel Pro Power’s aftermarket parts reliable?

6. How do I know which parts I need for my MG521?

7. What are signs that my MG521 transmission needs maintenance?

8. Do you offer technical support?

9. Can I purchase parts for other Twin Disc transmissions?

10. How do I place an order?

Order Twin Disc MG521 Parts Today

Marine Transmission Specifications & Applications of the Twin Disc MG521

Overview of the Twin Disc MG521 Marine Transmission

Key Specifications of the Twin Disc MG521

Common Marine Applications for the MG521

Most Common Engine Models Paired with the Twin Disc MG521

Cummins Marine Engines

These Cummins engines match well with the MG521’s torque tolerance and gear reduction options, particularly in trawlers and supply vessels.Caterpillar Marine Engines

Popular in fishing fleets and offshore supply applications, these Caterpillar platforms pair effectively with MG521 for continuous-duty workloads.MTU Marine Engines

Used in high-performance or large-displacement vessels, MTU engines provide high torque that the MG521 is built to manage reliably.Detroit Diesel Marine Engines

The MG521 is frequently used in vessel repowers or refits where these legacy high-horsepower Detroit engines are still in service.

Advantages of the Twin Disc MG521

Ideal Use Cases for the MG521

Additional Resources

Practical Guide To Servicing the Twin Disc MG521 Marine Gear

Introduction For Twin Disc MG521 Marine Gear

General Specifications For Twin Disc MG521 Marine Gear

Installation Guidelines For Twin Disc MG521 Marine Gear

Initial Startup Procedure For Twin Disc MG521 Marine Gear

Scheduled Maintenance For Twin Disc MG521 Marine Gear

Inspecting and Replacing Bearings and Gears For Twin Disc MG521 Marine Gear

Troubleshooting Common Problems For Twin Disc MG521 Marine Gear

Control System Integration For Twin Disc MG521 Marine Gear

Removal and Reinstallation For Twin Disc MG521 Marine Gear

Parts and Component Replacement Guide For Twin Disc MG521 Marine Gear

Rebuild Kit and Aftermarket Parts Overview For Twin Disc MG521 Marine Gear

50 FAQ’s – Frequently Asked Questions For Twin Disc MG521 Marine Gear

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588